TinyFPGA AX & BX

A tiny, low-cost, open FPGA dev board that packs a punch.

Funding ended on Apr 19, 2018 at 04:59 PM PDT.

Funding ended on Apr 19, 2018 at 04:59 PM PDT.

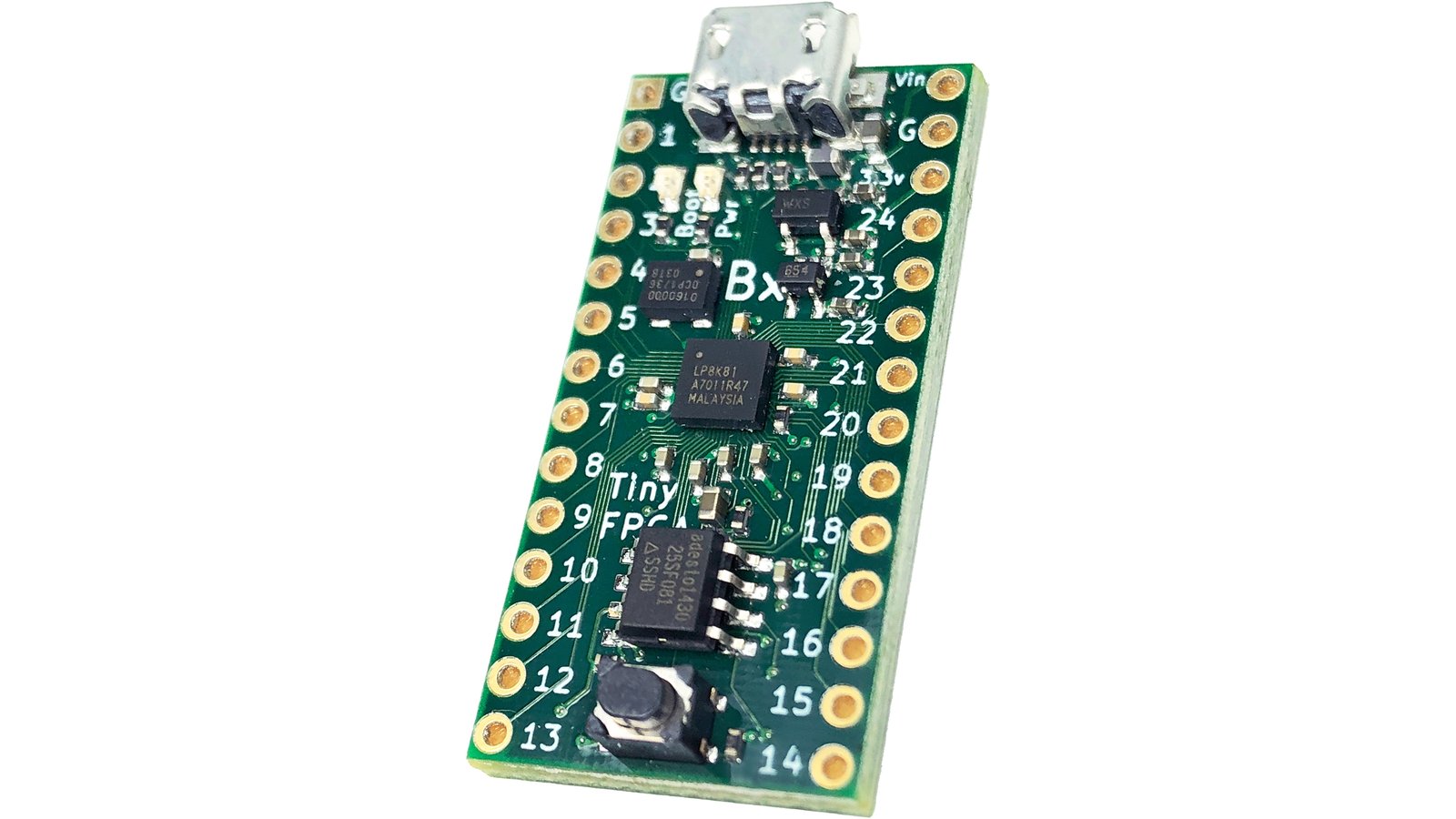

The TinyFPGA BX brings the power and flexibility of custom digital logic designs to the maker community. The BX module allows you to design and implement your own digital logic circuits in a tiny form-factor perfect for breadboards, small spaces, or custom PCBs.

This incredible power allows you to do things that are not possible with traditional microcontrollers. While microcontroller boards have a fixed set of peripheral devices on-board, the TinyFPGA BX modules can implement the exact peripheral devices needed to get the job done. It’s not software bit-banging, it’s the real deal implemented in digital logic. When the next project has different requirements, reprogram the TinyFPGA BX with a new design suited to the task.

The full potential of programmable logic devices allows for even more ambitious projects than custom microcontroller peripherals: augment a retro-computer with new capabilities, recreate an 8-bit computer from history, or design your own.

If you don’t know what the big deal is with custom digital logic, then here’s a great way to learn. Place a TinyFPGA BX down on a breadboard and get to work interfacing it with LEDs, switches, rotary encoders, and any other peripheral, sensor, or interface you might like to try. The low cost of the BX and open-source ecosystem make this an excellent way to get started on a new adventure with digital logic.

Whether you are a hobbyist looking to expand your capabilities, a professional prototyping a new product, or a student learning the ropes of digital design, the TinyFPGA BX can help you on your way.

Have you ever wanted to use an FPGA in a project, but the available boards were too big or expensive? New to FPGAs and want to learn how to use them? Want to put an FPGA on a PCB you are designing but don’t want to worry about power delivery, clocking, configuration flash, or difficult surface mount packages? If you answered "yes" to any of these questions, then the TinyFPGA BX can help!

The TinyFPGA BX is designed for makers and hobbyists. It puts you in control by taking care of FPGA support details and getting out of your way. It provides an easy to use component for your projects. It’s small enough to fit comfortably on a breadboard for learning or prototyping. When you’re ready, you can design a custom PCB incorporating a TinyFPGA BX module.

The TinyFPGA BX module is completely open hardware and open source. If you move beyond the need for through-hole components, you may decide you want to re-use or adapt the design for your own creations.

The TinyFPGA BX is a small FPGA module with all of the components and circuitry required for the FPGA to function taken care of for you. To develop for the board you create a design in your favorite digital design language (Verilog/VHDL, Migen, and Chisel are some popular options). Alternatively, you can use a schematic entry tool like IceStudio. A schematic entry tool allows you to graphically draw a digital circuit to be implemented on the FPGA.

Once you have a design, you can program it onto the TinyFPGA BX module over USB. All the functions your design implements will now be able to interface with the outside world through the module’s IO pins.

There’s plenty of space on either side for connecting jumpers or components. There is no smaller FPGA board available with this many logic resources!

Forget proprietary and expensive USB interface chips, the TinyFPGA BX implements its own open source USB bootloader! Upon power-up, USB bootloader is loaded from SPI flash and becomes active. It appears on the host computer as a virtual serial port device. The programmer software automatically detects the board and uses the serial interface to program your design onto the board. Once your design is loaded in the SPI flash, the board reboots and loads your design without the bootloader. To update your design just press the reset button and the bootloader will be activated again.

The TinyFPGA Bootloader has features that proprietary chips do not have. In addition to lowering the cost of the board for users like you, it also contains metadata on the SPI flash in an open JSON format. This metadata contains:

This metadata, along with the dedicated programmer tool, makes the TinyFPGA BX boards easy to use.

If you want to see all the metadata stored on all the boards connected, you can get a full JSON listing of the metadata annotated with the serial port name they are connected to.

For technical details and source code see the TinyFPGA Bootloader GitHub repository.

The TinyFPGA BX improves upon the previous B2 model in every aspect and the PCB layout is no exception. In addition to nearly doubling the number of user IOs, the new PCB layout also an improved PCB layout and power delivery:

In addition to the free tools from Lattice for developing with the iCE40 FPGAs, the TinyFPGA BX is also supported by the completely open-source IceStorm FPGA toolchain.

IceStorm has enabled incredible tools like IceStudio to be developed. If you are new to the world of digital logic, IceStudio is a great way to learn and make with FPGAs.

IceStorm currently supports the TinyFPGA B2 and I will be working closely with its creators to implement support for the TinyFPGA BX as well.

If graphical schematic entry is not your thing, you can use your own favorite text editor or try out the APIO-IDE project. APIO-IDE builds on top of PlaformIO-IDE and is a great open-source development environment for FPGAs.

Besides the TinyFPGA BX, there are a few different FPGA boards that have adopted a smaller form factor suitable for breadboards. These boards vary in availability, price, capacity, features, and license. A section on FPGA power delivery comparisons has been added since it is easy to overlook and can have a large impact on stability and signal integrity.

| TinyFPGA BX | Lattice ICEstick | UPDuino v2.0 | bugblat TIF | |

|---|---|---|---|---|

| License | OSHW | Closed | Closed | Closed |

| Stock | Pre-Order | In Stock | In Stock | Out of Stock |

| FPGA | ||||

| Model | iCE40LP8K | iCE40HX1K | iCE40UP5 | LCMX02 1200/4000 |

| Logic Capacity (LUTs) | 7680 | 1280 | 5280 | 1280/4320 |

| Internal RAM (bits) | 128k | 64k | 120k + 1024k | 64k/92k |

| Multipliers | 0 | 0 | 8 | 0/0 |

| Peripherals | ||||

| USB Interface | OSHW Bootloader | FTDI 2232HL | FTDI 232HQ | SIL 2112 |

| User IOs | 41 | 24 | 34 | 16 |

| Onboard Clock | 16 MHz MEMS | 12 MHz MEMS | 12 MHz (from FTDI) | 48 MHz (from SIL) |

| Flash | 8 MBit SPI Flash | 32 MBit SPI Flash | 32 MBit SPI Flash | 80KBit/96KBit FPGA User Flash |

| FPGA Power Delivery | ||||

| Dedicated Ground/Power Planes | Yes | Yes | No | Yes |

| Dedicated FPGA Bypass Capacitors | 8 | 18 | 2 | 4 |

| Board Ground Connections | 6 | 6 | 3 | 3 |

| Software | ||||

| Open Source Toolchain | Yes | Yes | Yes | No |

| APIO Support | Yes | Yes | No | No |

| IceStudio Support | Yes | Yes | No | No |

The TinyFPGA BX boards will be manufactured by PCBWay in China.

I have been using PCBWay for all of the TinyFPGA boards including the BX prototypes. The process of manufacturing the prototypes with PCBWay has found some design rule violations that I was able to clean up. It also ensured that they would be able to assemble the boards with the unique BGA footprint that is present on them. The prototype run of 20 boards came back with every one of them 100% functional.

PCBWay offers a full turnkey service for fabricating the PCBs, sourcing components, and assembling the boards. To help reduce costs I will be working with Arrow to source some of the key components of the board.

After the crowd-funding campaign ends, the full manufacturing run will be ordered from PCBWay along with components from Arrow. When PCBWay receives payment, they will begin fabrication of PCB panels with TinyFPGA BX boards. During PCB fabrication, the full electrical connectivity of each board is tested and physical characteristics are optically inspected. The panels will likely be finished by the time the components arrive for assembly.

After assembly, the boards are broken out of the panels using a "pizza cutter" tool. It is a specially designed tool that seperates the boards from their panel without mechanically stressing the components.

The individual boards are packed and shipped to TinyFPGA in Sacramento, California. Here they will be tested for correct functionality and programmed with the USB bootloader.

The testing and programming take place on a dedicated test-jig. The test-jig is currently powered by a Teensy 3.6 microcontroller board. This is a ready-made module that can easily be replaced if there are any issues with it. It also has a built-in micro SD card slot that is used to contain the test and production firmware. Below you can see the test-jig used to test and program the prototypes.

The test-jig pushes the board onto a set of pogo-pins that contact all of the testpoints and headers on the bottom of the board. Through these pogo-pins the board programming and testing procedure is executed automatically:

Passing boards are then packaged in an ESD safe bag and labeled. At this point they are ready to be shipped to backers!

There are many things that can go wrong when manufacturing hardware. The TinyFPGA BX is a proven design with a few dozen working prototypes, but this doesn’t mean that higher volume manufacturing is guaranteed to go smoothly. Here’s a list of the likelier risks to production:

For whatever reason, components that used to be plentiful one day can come under a crunch during manufacturing. This could be due to someone else buying all the parts for their own production run or a supply chain issue for the original manufacturer of the component. So far this hasn’t been an issue for the previous B2 version or for the BX prototypes.

When just a few PCBs are manufactured yield issues might not become apparent. When a larger production run is ordered there could be yield issues that could require a redesign or additional run that will take more time.

Issues with components, PCB design, solder paste stencil, or assembly equipment can cause issues with PCB assembly. The TinyFPGA BX has an increased risk of a hit to the assembly yield due to the unique BGA footprint for the FPGA. So far, all of the prototypes that have been assembled have not exhibited any issues with the BGA footprint, but it is possible it could affect the assembly yield in higher volume production. If the yield is very bad, it would require a redesign. If the yield is good enough, then it should not cause any delays.

The TinyFPGA BX is based on the successful B2 board. In addition to the basic design of the board itself, it also shares a lot of the test-rig firmware and hardware. This similarity reduces the challenges, but the crowd funding campaign scale could present an additional challenge.

The TinyFPGA BX boards are manufactured by PCBWay in China. They have been great to work with, but it can be tricky to get key components to China economically. Luckily I will have some help in getting this done.

Every single board coming from the manufacturer needs to be functionally tested. This means the voltage levels, FPGA IOs, clock chip, SPI flash, and LEDs must be tested and verified to be assembled correctly. After the board is tested, it needs to have the USB bootloader programmed onto the SPI flash along with a unique ID. This is all done automatically by the test-rig. The test-rig for the BX has been developed and validated using the BX prototypes.

Right now the programming phase of the tester is running a bit slow and I will be working on speeding that up.

For previous manufacturing runs for TinyFPGA I have broken out the boards from panels and finished the edges myself. This is a real pain in the rear and I have a different plan for the BX. The assembly house has a "pizza cutter" machine that seperates the boards with nice smooth edges. I will be paying them a little extra for this service so I can ship the boards faster.

Thanks for reading the whole campaign, I have worked hard on this project and I am excited to get it out for makers everywhere to use! You can support the project by selecting one of the pledge levels at the very top right of the page. When you get your TinyFPGA BX and make something, let me know. I love seeing the projects people make with TinyFPGA boards, even if you’re just learning and it’s a simple blinking light!

Produced by TinyFPGA in Sacramento, CA.

Sold and shipped by Crowd Supply.

Thanks for supporting TinyFPGA!

Want to buy this item? Check the current project page for the latest information.

A total of 25 TinyFPGA BX boards with a nice discount. The TinyFPGA BX boards are perfect to run a hands-on workshop, teach a lab on digital logic and FPGAs, or to keep in stock at a maker space.

Want to buy this item? Check the current project page for the latest information.

The most feature-rich TinyFPGA with the biggest FPGA, most IO, most flash, and programming directly over USB.

Want to buy this item? Check the current project page for the latest information.

· tinyfpga · tinyfpga.com

TinyFPGA is a one-man endeavor to bring the incredible capabilities of FPGAs to makers around the world. Luke started TinyFPGA while looking for an FPGA that could be used in a breadboard. When no suitable candidate was found he took it upon himself to develop a tiny FPGA dev board.

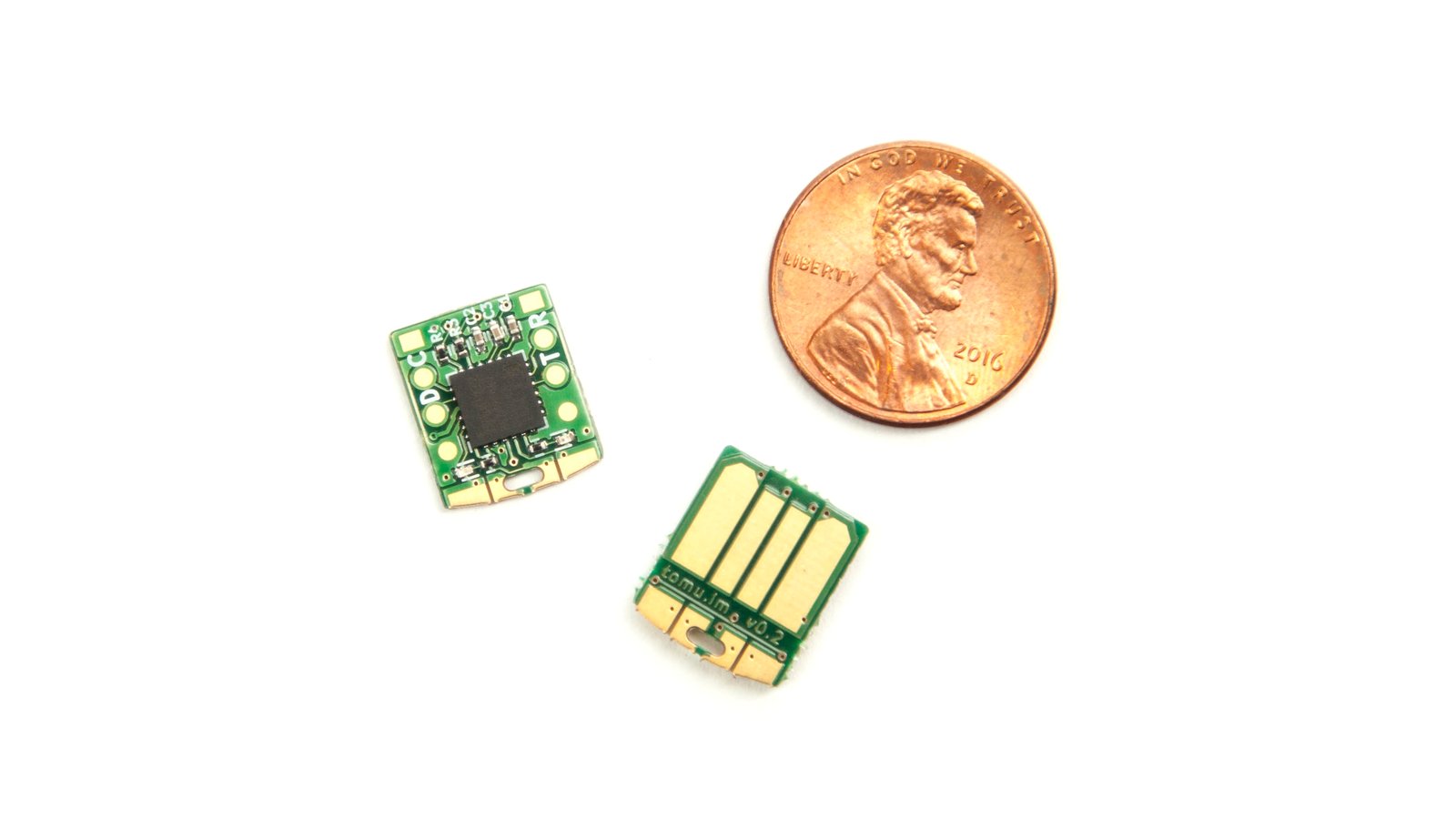

An ARM board that fits inside your USB connector

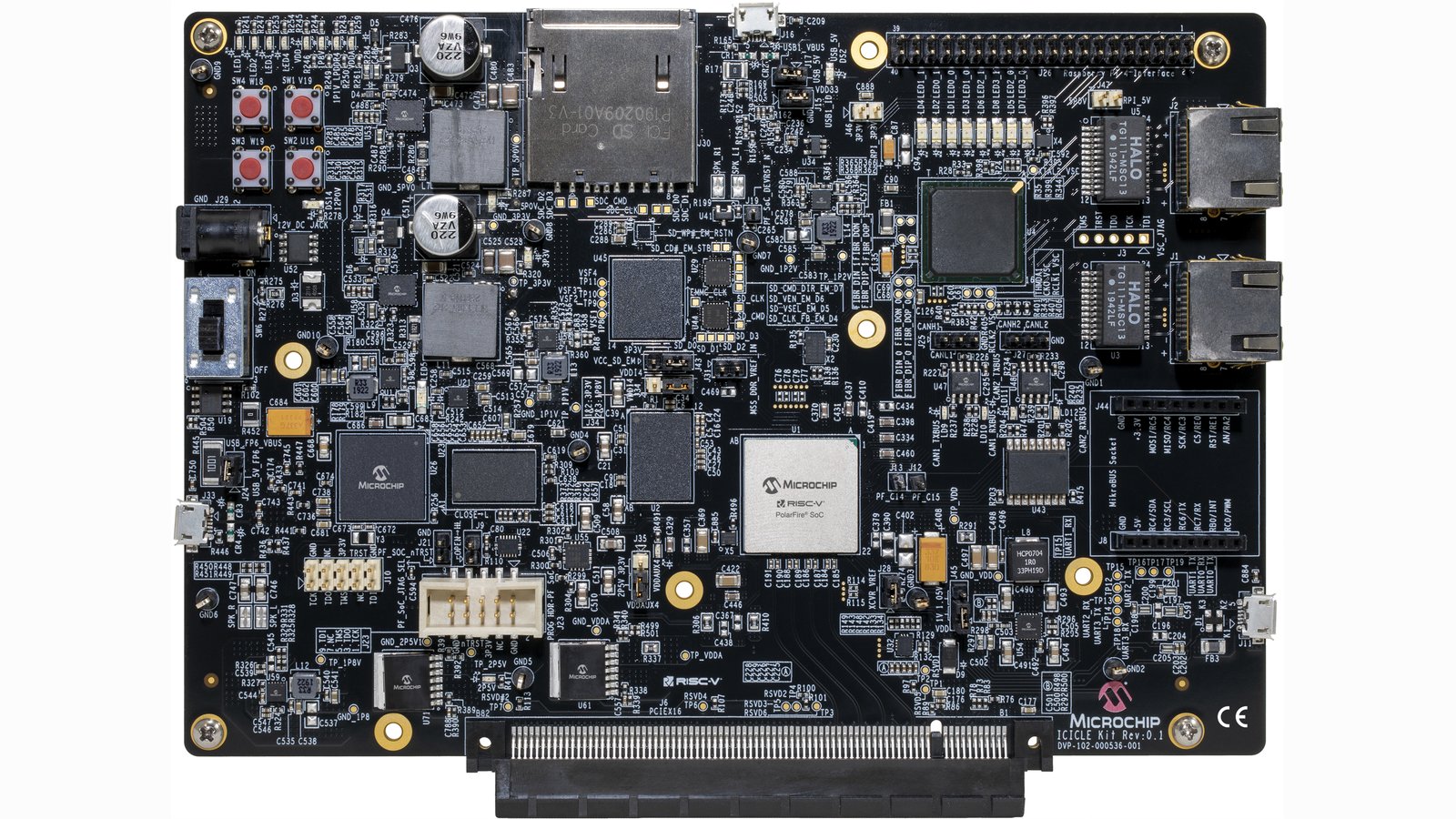

A low-cost dev kit for Microchip's PolarFire SoC, a low-power FPGA integrated with a hardened quad core 64-bit RISC-V microprocessor subsystem

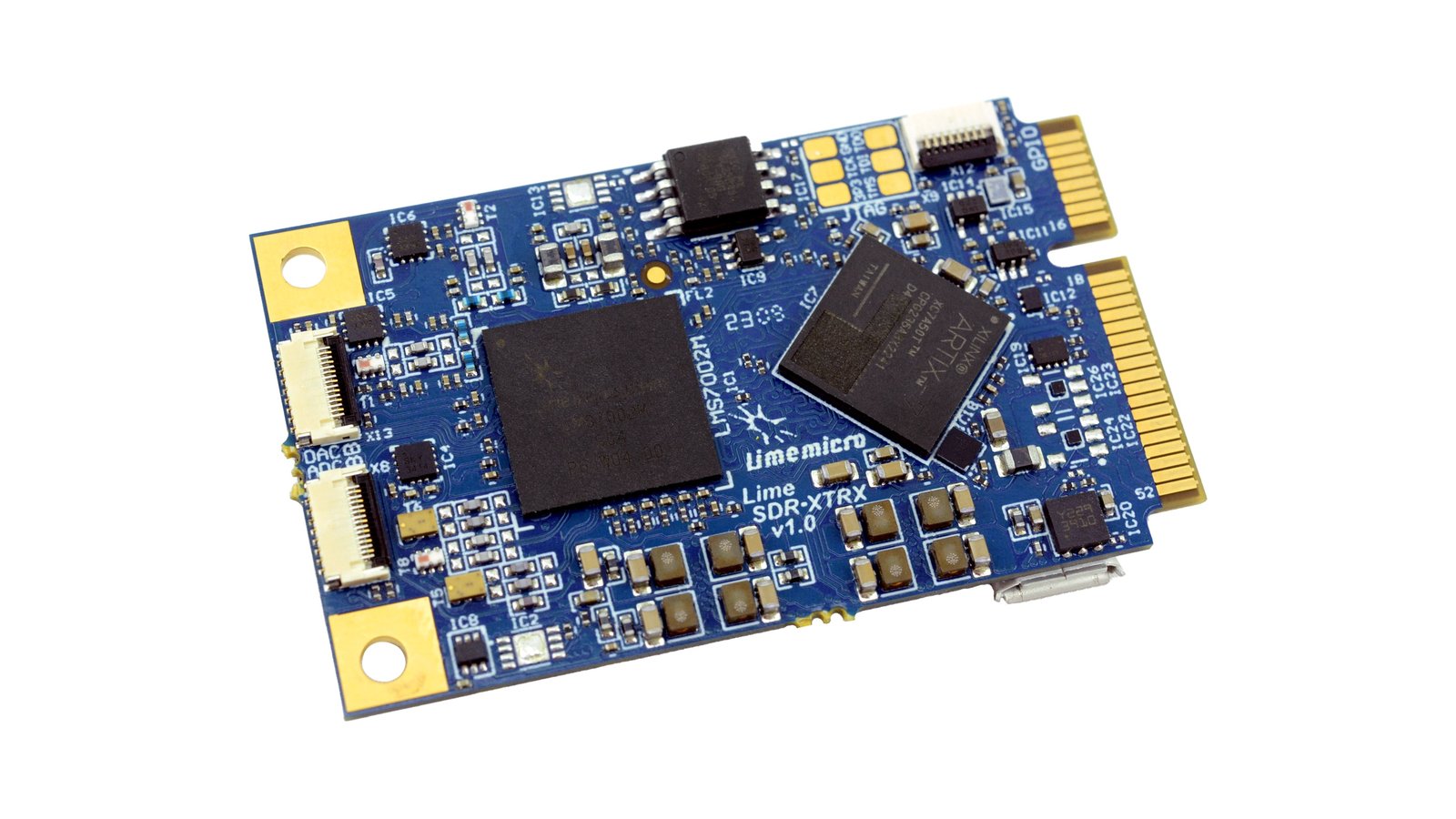

An embeddable, high-performance SDR in a Mini PCIe form factor