Project update 5 of 10

Our Enclosure: Balancing Design, Functionality, and Manufacturing

by Dmytro KHello everyone,

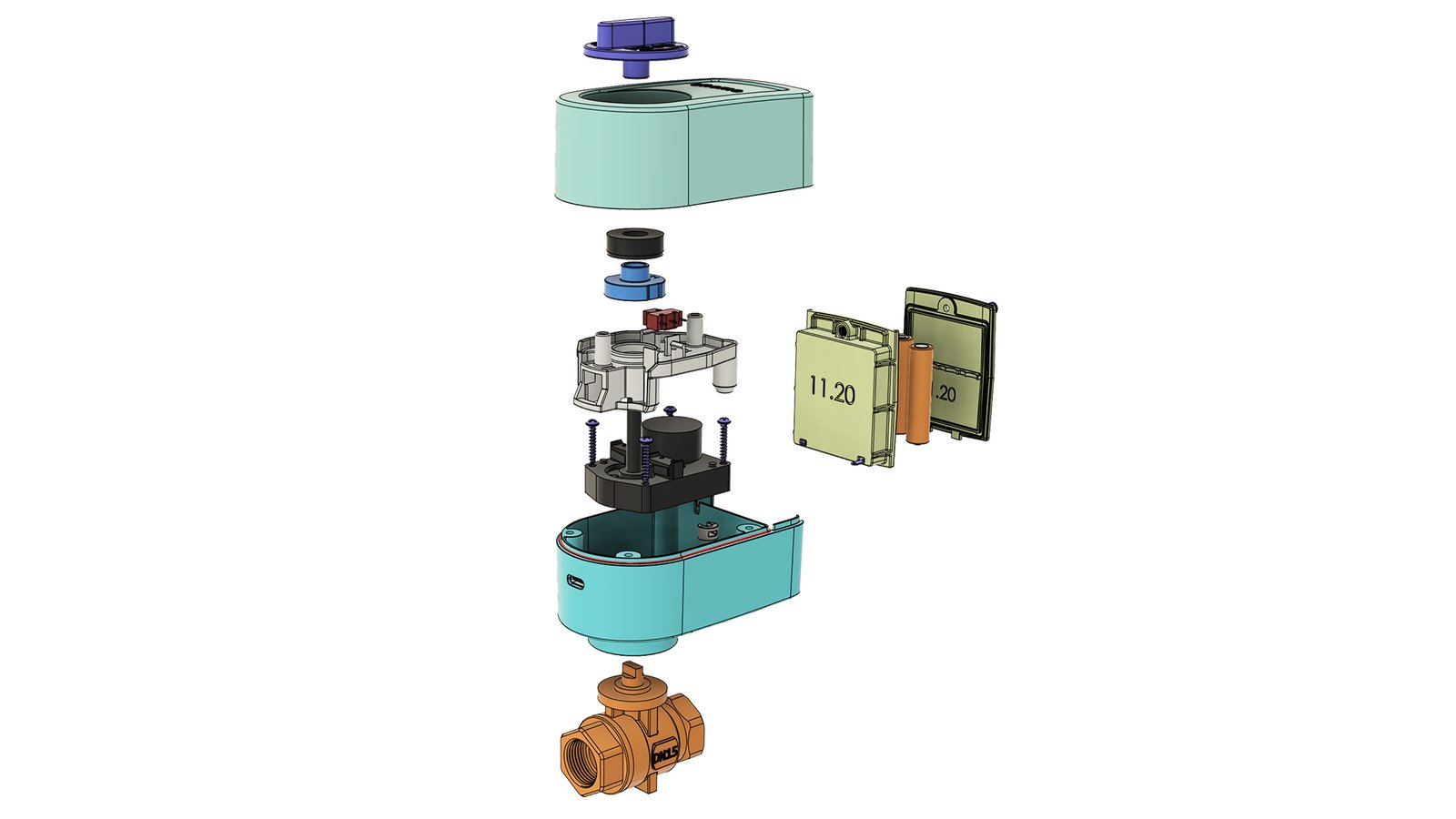

I think our device is unlike many products on Crowd Supply because, in addition to electrical and software design, mechanical design plays a large role in our product. Therefore, today I will talk about this aspect of True Wireless Valve. I hope you will be interested.

Mechanical Design and Tolerances

One of the primary challenges in mechanical design is creating a functional product despite variations in manufacturing tolerances. Our design involves not just the enclosure but also many parts that need to assemble and function properly. While everything may appear perfect in CAD models, real-world manufacturing inevitably introduces slight deviations from ideal dimensions. These tolerances can accumulate, leading to significant differences from the intended design, especially when assembling a product with many components from various suppliers.

Additive manufacturing has greatly simplified the production of small batches of products. However, even with the latest technologies and equipment, tolerance issues remain. Even ordering the same parts from the same supplier can yield slightly different results each time. Our product comprises numerous unique parts and we have designed these parts to minimize the impact of these variations.

The Flag Mechanism

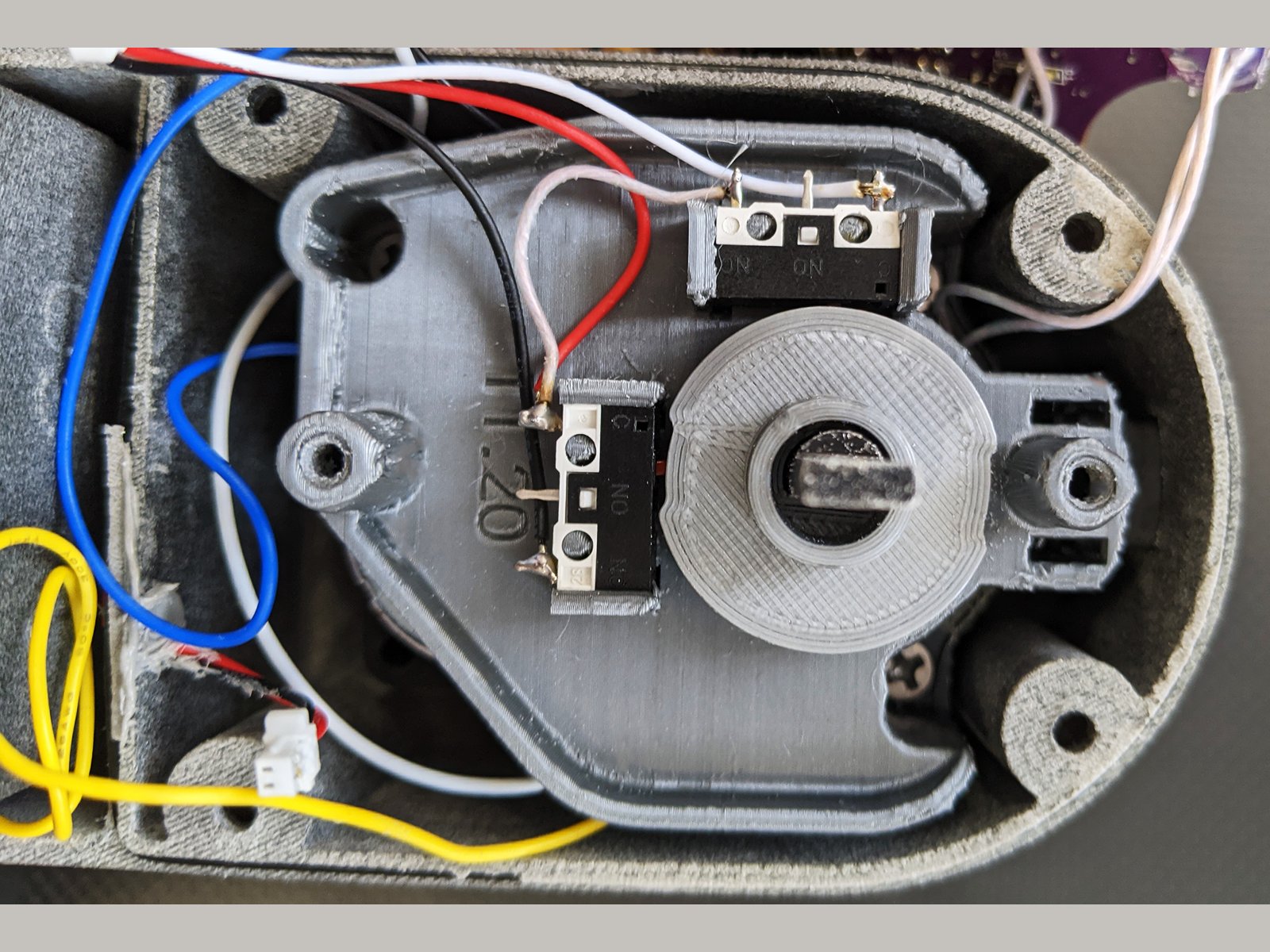

One of the critical mechanisms in our valve is the flag attached to the handle, which triggers the corresponding limit switch.

The signal from these limit switches is used to update the status in Home Assistant. Initially, the limit switches were mounted on the frame that also held the PCB, while the handle was connected to the gearbox. Any deviations in these components could lead to incorrect activation of the limit switch, resulting in improper valve control (e.g., the gearbox turning off before the valve is fully open or closed). This issue could be easily resolved in single-unit assembly by manually adjusting each component’s position. However, scaling up production required a more efficient solution.

Waterproofing and IP Rating vs Tolerance

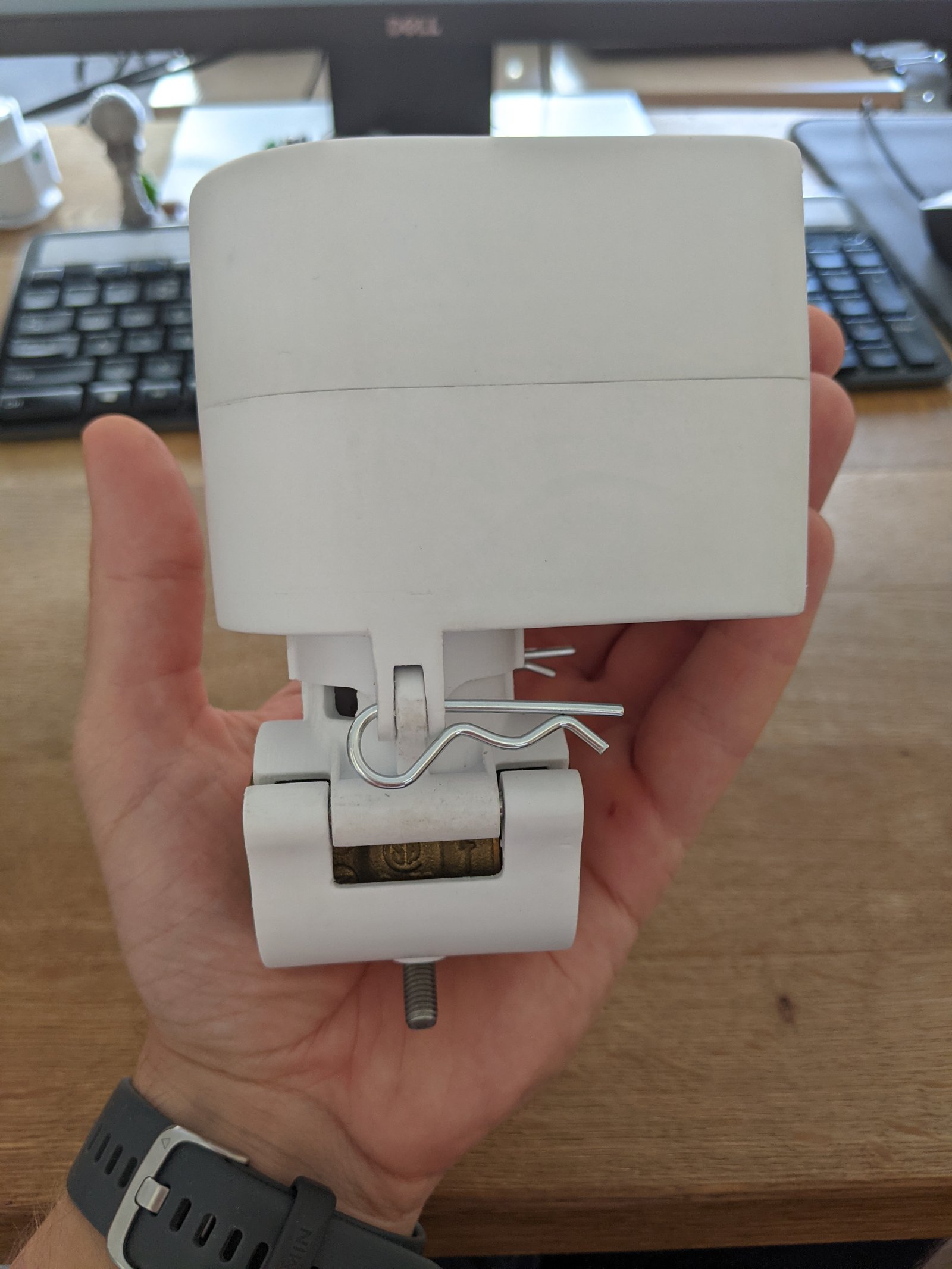

Our first version had half the functions of the final version and was nearly twice the size.

The next generation sacrificed water protection to reduce size (by approximately 30 percent),

However, due to high demand for a water resistance device, we reinstated waterproofing features. Achieving an IP65 rating required a more complex design and stricter manufacturing requirements, but we managed to incorporate these without significantly increasing the product’s size.

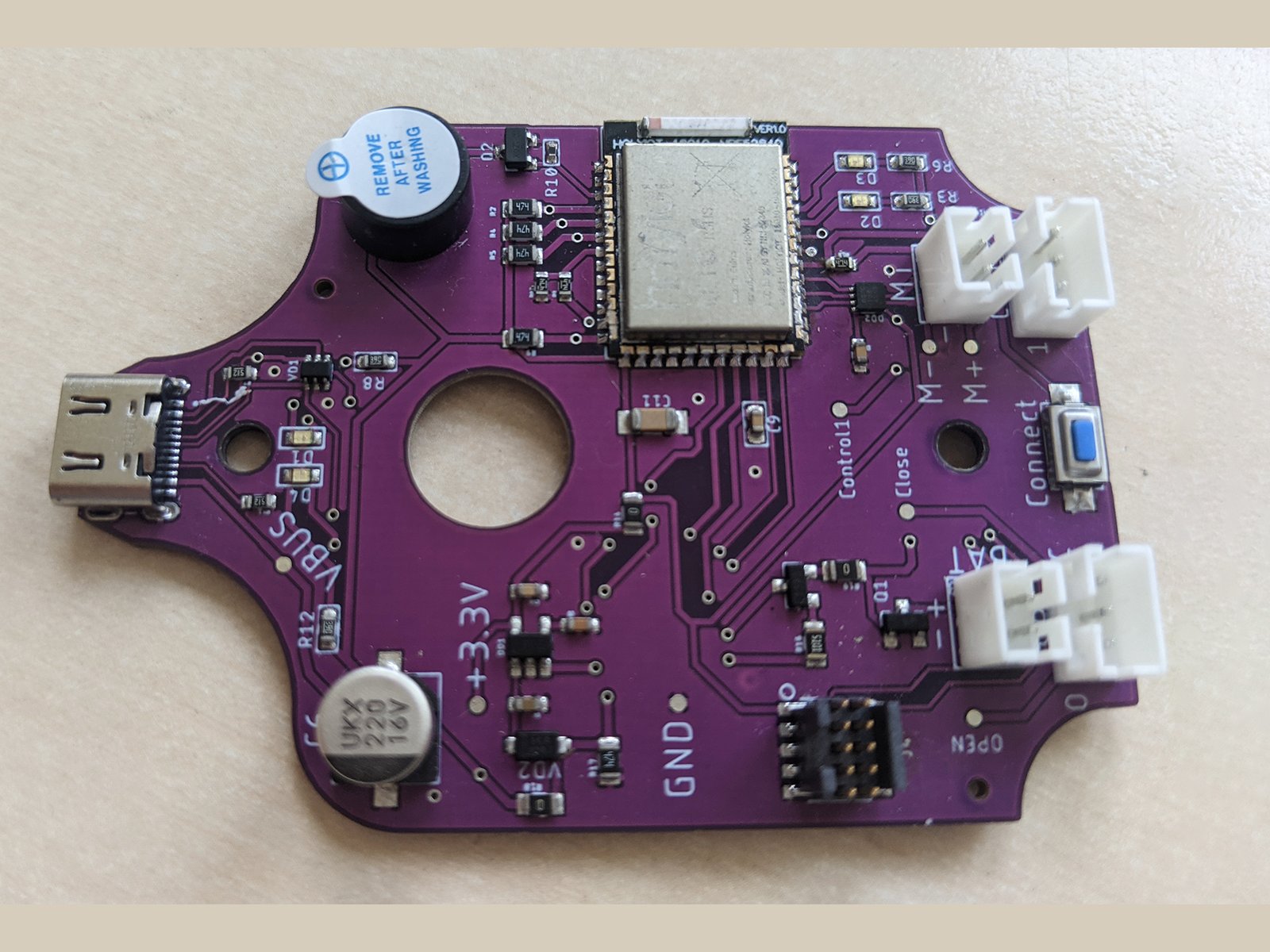

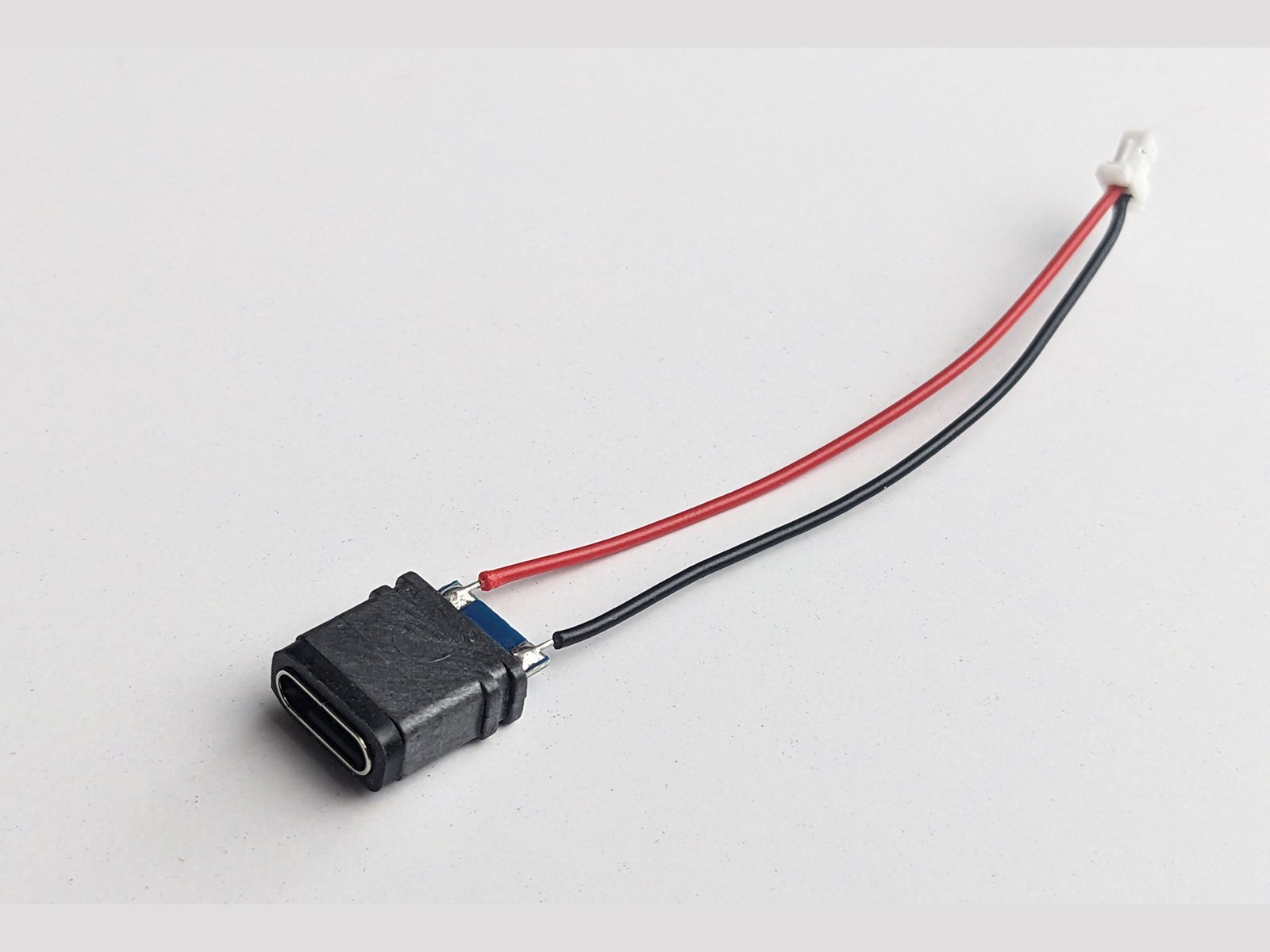

We had to seal several openings: the USB port, handle, battery compartment, and the connection between the main body halves. Originally, the USB Type-C port was integrated into the PCB but, to achieve IP65 protection, it was redesigned as a separate component, allowing for independent mounting of the PCB and connector. Ensuring the rubber seal around the USB port was tightly compressed required precise positioning and so could not depend on PCB positioning.

For the handle, we initially tried to use a standard grommet that are very often used to protect a cable from cuts and tears. We designed that handle and housing that installed it with tension.

But long-term testing revealed it was not suitable due to the rotational movement of the handle and changes in the grommet’s rigidity over time. We switched to an industrial-grade, spring-loaded rotary shaft with seals and bearings made of high-quality rubber, which undergoes strict quality control and meets our requirements.

The battery compartment was easier to seal, compared all the other parts in our design; we created a pocket and formed the seal directly within it.

For the connection between the body halves, we used an O-ring, a common and reliable solution. However, ensuring the O-ring was properly compressed required precise manufacturing, which led us to choose more expensive but accurate production technologies.

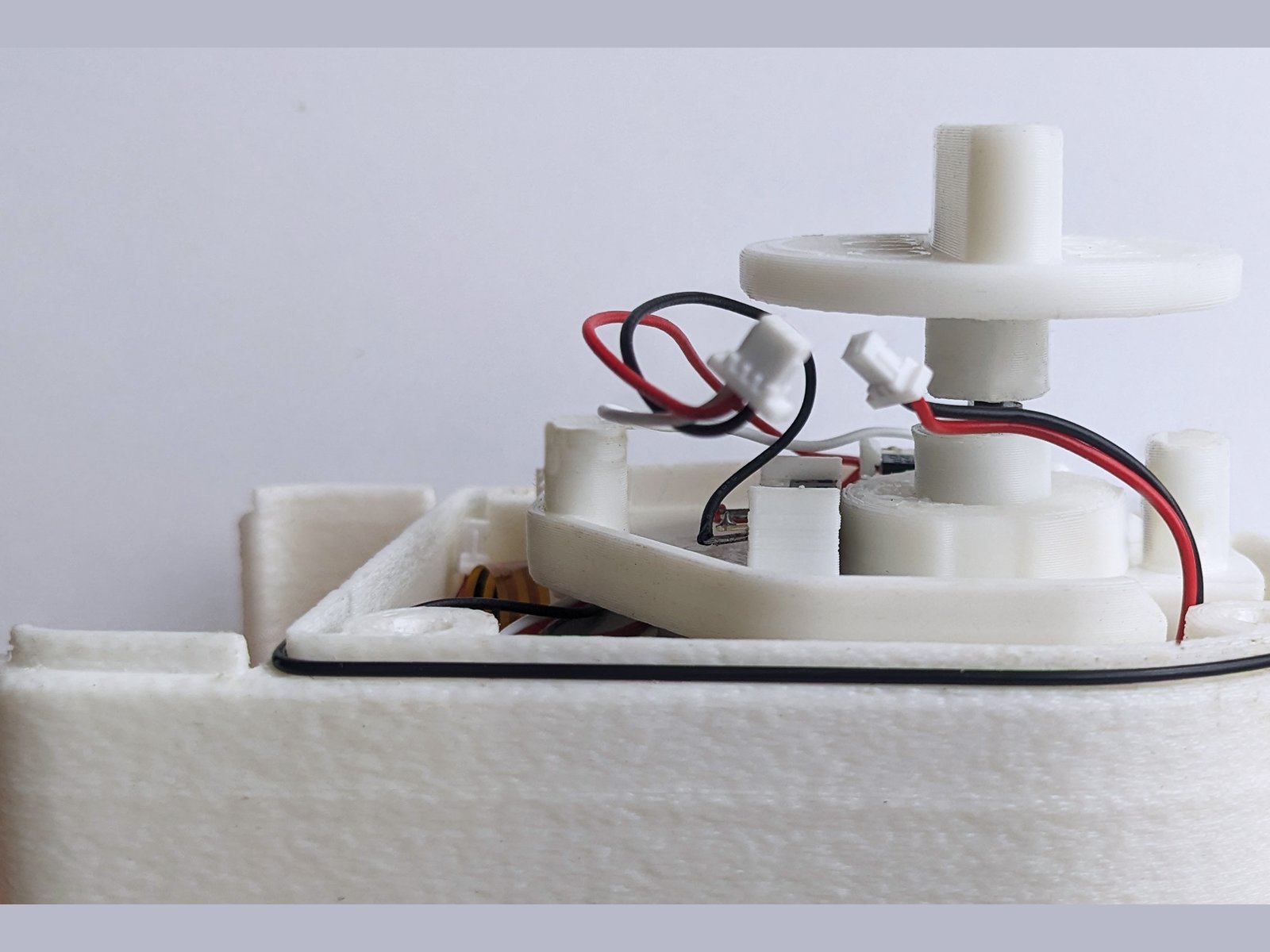

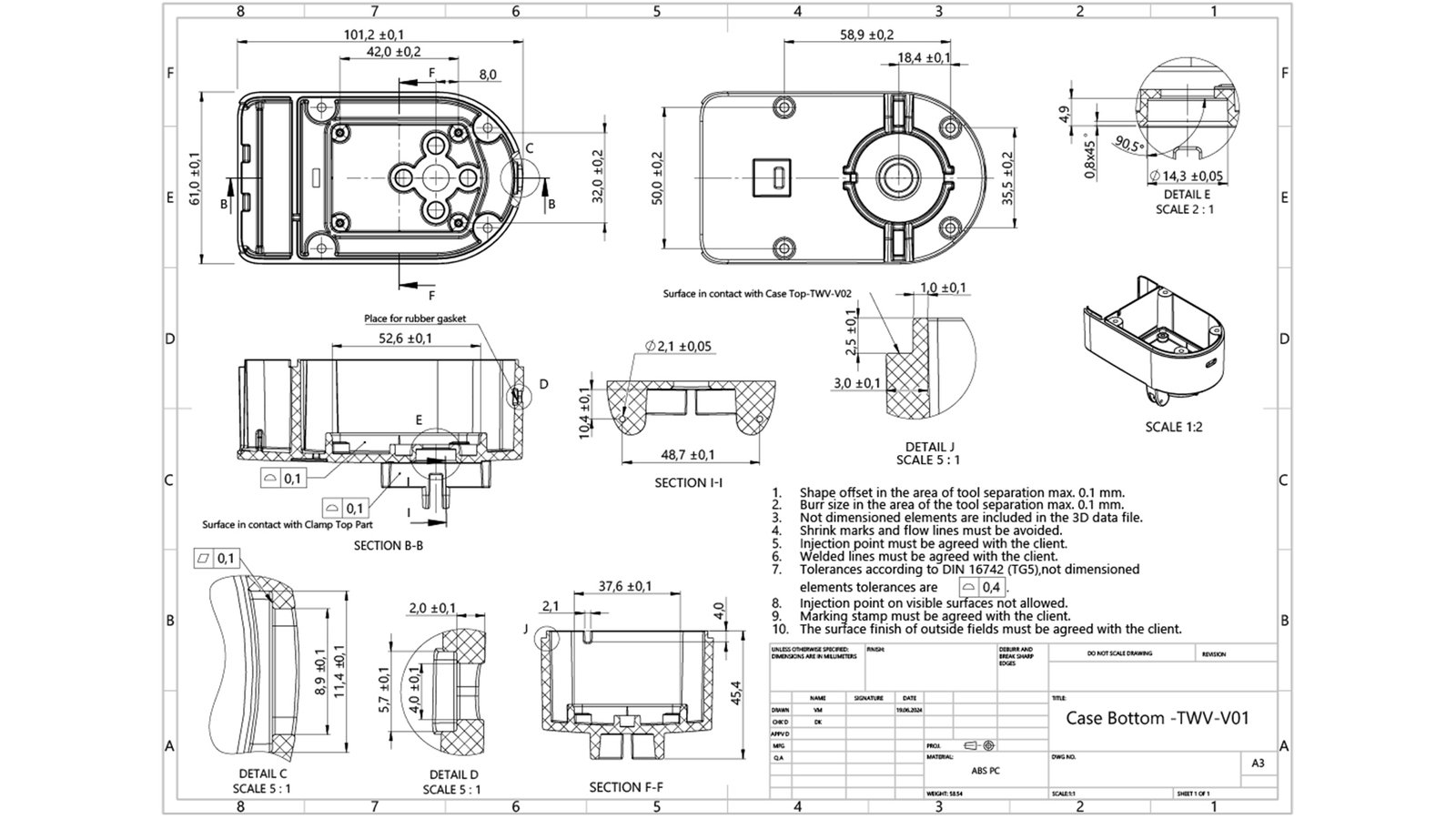

Initially, we aimed to use injection molding for the body parts due to its low cost and high precision, our parts are ready for manufacture and pass DFM and DFMA stage.

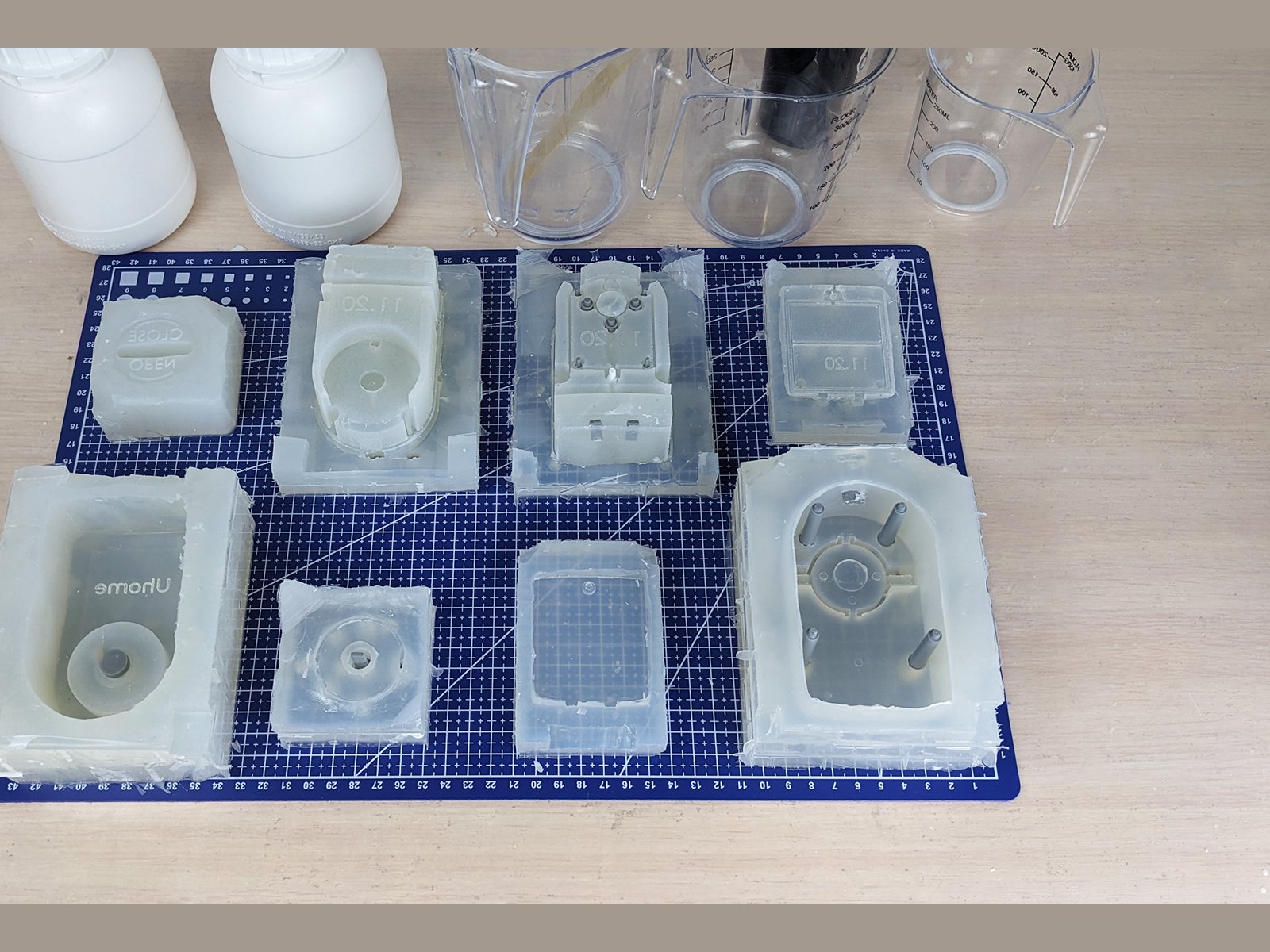

However, this method requires high initial investment in tooling, so we needed to find another way to produce the first batch. We spent considerable time on silicon molding, a method similar to injection molding but using silicon molds. Although suitable for small batches, the tolerances were too wide.

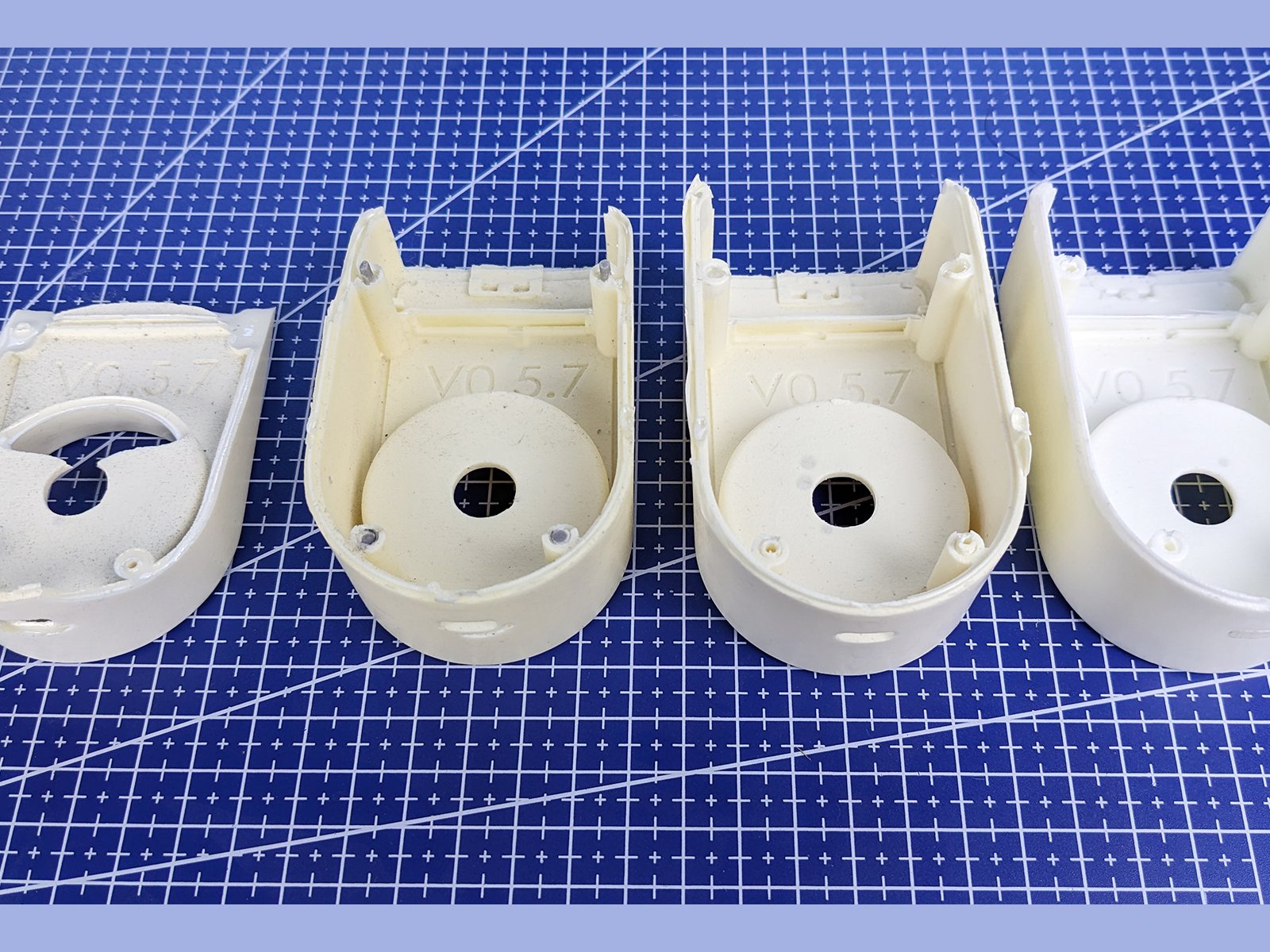

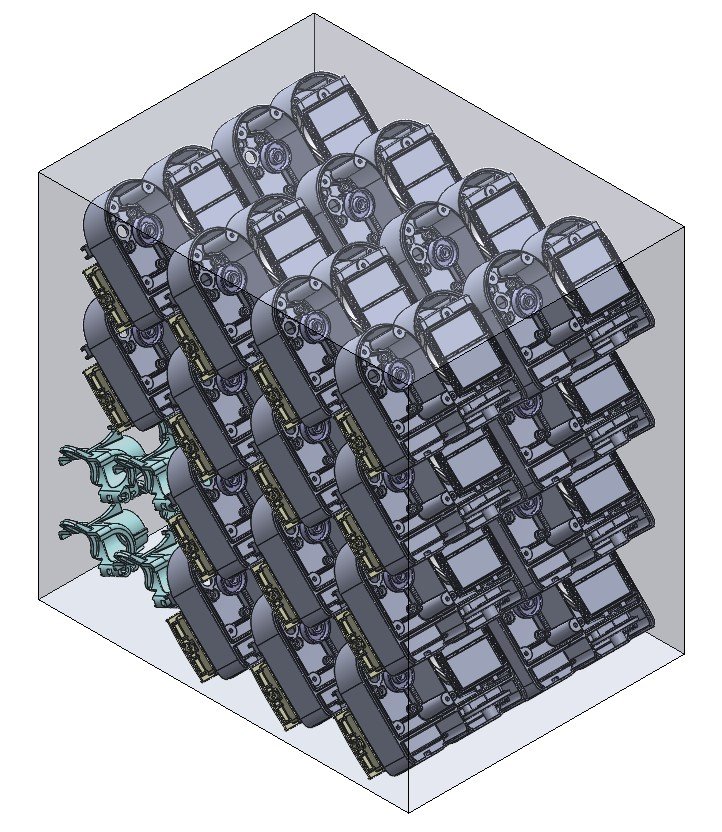

Ultimately, we returned to 3D printing, opting for Multi-Jet Printing (MJP) technology. Though more expensive than FDM, MJP provides much better dimensional accuracy and inherent waterproofing, unlike FDM-printed enclosures. To decrease the cost of printed parts, we found a supplier that allows ordering the whole printing volume of this type of printer. We just need to set up all our parts in the most optimal way to use this volume while at the same time following the requirements for MJP. We managed to put 25 sets in the available printing area. This order option helped us cut 15 percent off the price of MJP printed parts.

As we transitioned to using MultiJet Printing (MJP) technology for producing TWV enclosures, we encountered significant challenges in achieving the desired color options. MJP technology, while superior in terms of dimensional accuracy and inherent waterproofing, predominantly produces parts in a natural gray color.

Achieving the sleek white finish we envisioned proved complex and costly. This process typically requires either pre-colored resins, which are expensive, or post-processing techniques such as painting, which add additional time and cost. Despite these hurdles, we prioritized quality and aesthetic consistency, ensuring that our enclosures not only met functional requirements but also aligned with our design vision.

Looking Ahead

We hope this update has given you a clearer picture of the mechanical design challenges and solutions that shaped TWV. With the bulk of our crowdfunding campaign already passed, your support is more crucial than ever. Further, your feedback and participation are invaluable as we continue to enhance and evolve True Wireless Valve to better meet your water management needs. Join us in redefining smart home water systems with TWV!