Project update 3 of 10

Engineering the TWV: Designing for Dual Control

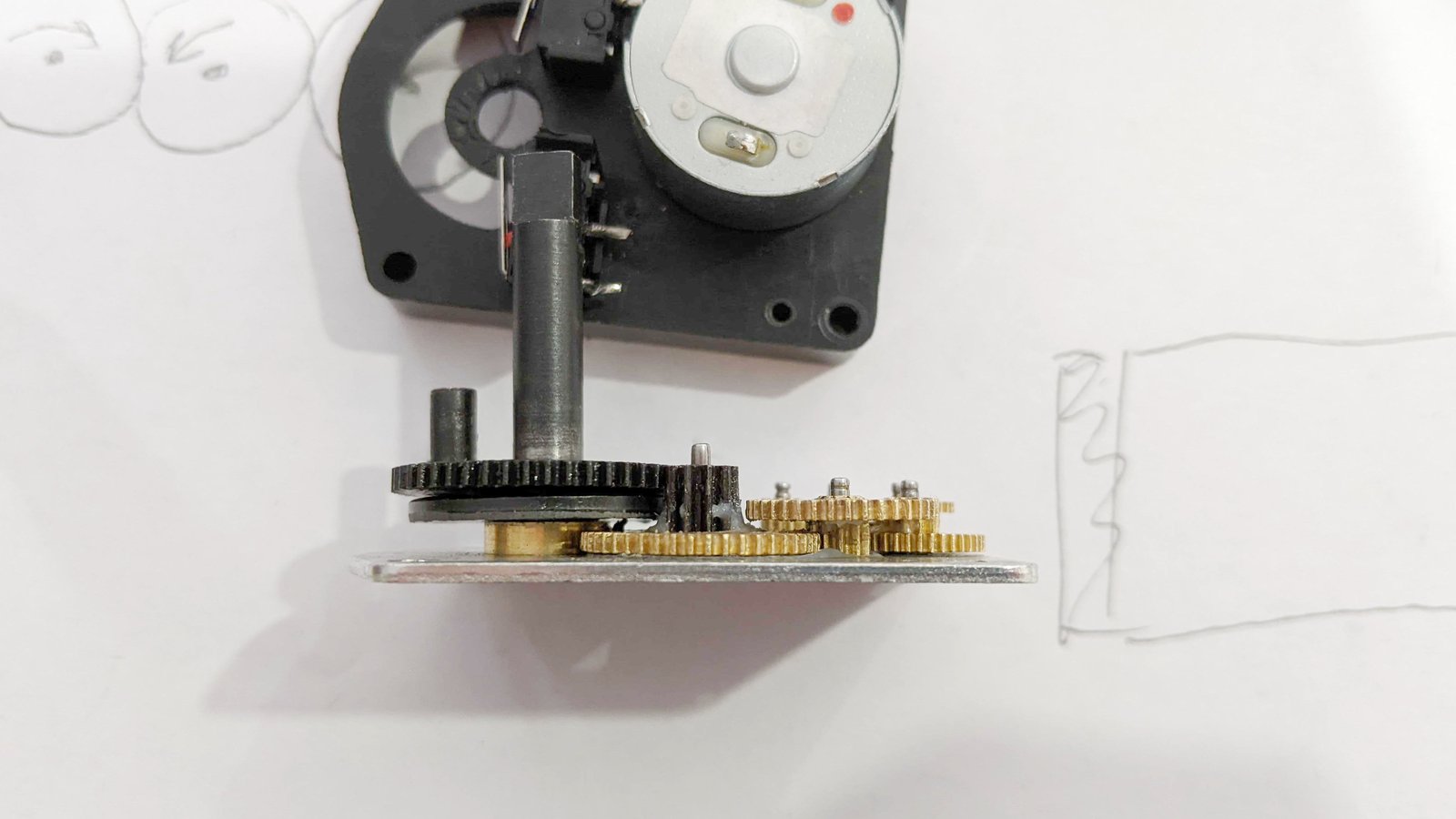

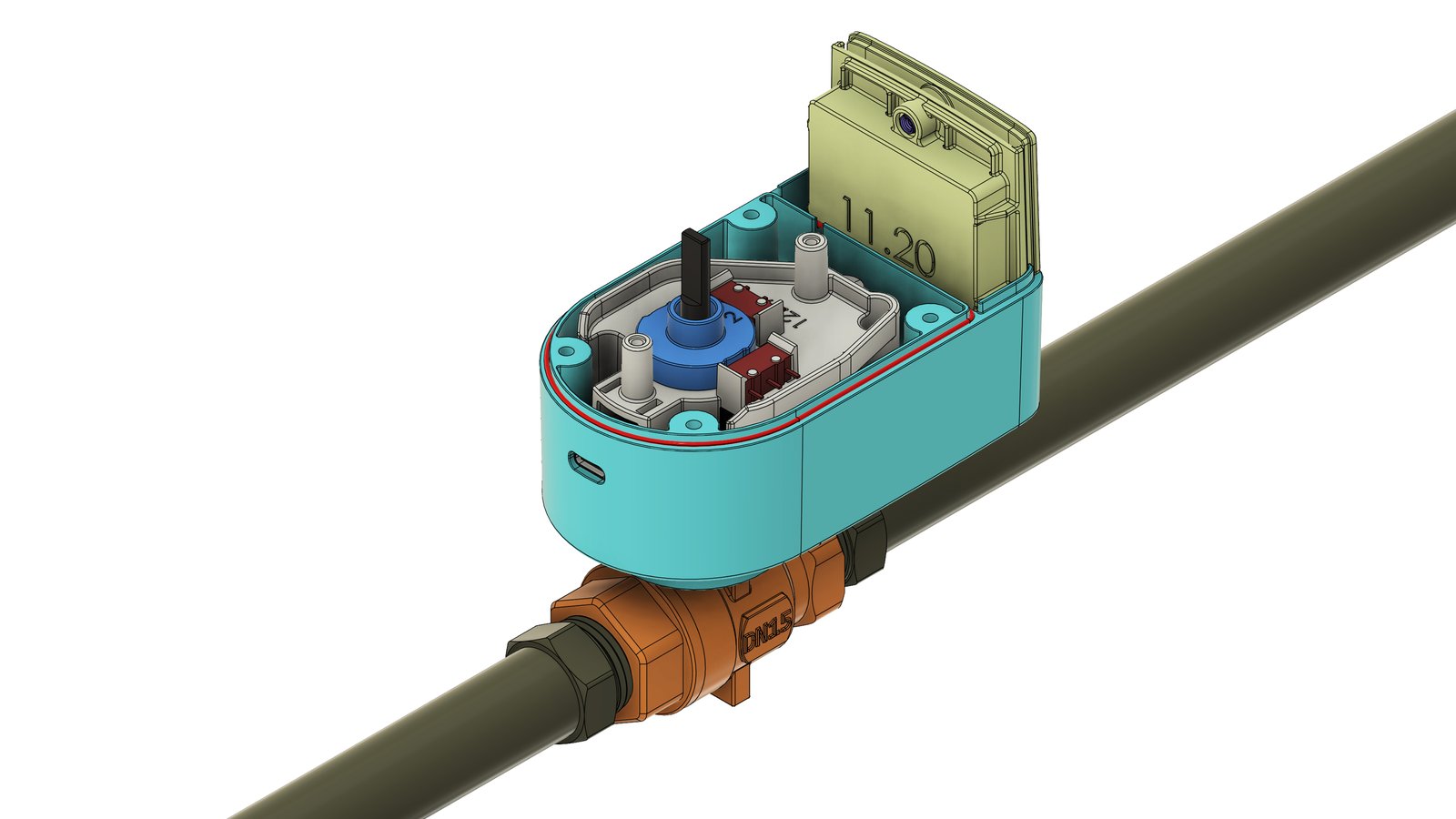

by Dmytro KToday we’ll discuss one of the main components of the True Wireless Valve (TWV): the gearbox.

Almost all electric motors need to have a high rotation speed to close your valve, but at the same time, they lack sufficient torque (the force required to turn the valve). The solution is to use a gearbox that reduces the rotation speed of the output shaft while simultaneously increasing the torque. We aimed to create as compact a solution as possible and sought the necessary balance between the power (size) of the motor and the gearbox’s gear ratio. We settled on a ratio of 1 to 3500, which means for one complete rotation of the output shaft, the motor must make 3500 rotations, but at the same time, the torque at the shaft will be 3500 times greater than the motor can generate.

At the start of the project, we decided that we wanted to retain the ability to operate the TWV just like a conventional valve. This was in contrast to many market alternatives, which lacked a manual handle and offered only system-controlled operation. The absence of a manual option in these designs typically stemmed from the high gear reduction ratio, making manual operation difficult. While some models did feature a handle, they required users to press an additional button to disengage the handle from the gearbox, complicating the manual operation.

Not only is this inconvenient, but the valve’s status in the system could also fail to reflect reality. For example, you might have opened the valve manually, but the system would still show it as closed; we wanted to avoid such scenarios. After researching all available solutions, we found a gearbox that allows motor operation while the handle remains engaged with the gearbox (without pressing any additional buttons). This is achieved through a plate with a slit that allows the handle to be turned 90 degrees from any position.

However, with the chosen gearbox, the issue of accurate feedback during manual operation persisted. Initially, we considered using encoders, but they were dismissed due to their high power consumption. Potentiometers were also excluded because of their low precision. Over time, we opted for a simpler and more reliable solution. We augmented the design with additional limit switches, which were already integrated into the gearbox. This modification enabled us to accurately determine the valve’s position, whether operated manually or via the system, ensuring consistent performance under all conditions

Now, you can operate your valve however you find convenient without worrying that it might affect your automations or scenarios.