Hello everyone,

As you´ve probably already noticed, we are successfully funded! This was only possible with your fantastic support, so thank you very much. Our dream of making a professional, open source, vapor phase accessible to many people is coming true.

We want to keep you up-to-date throughout the whole process of designing for manufacturing and certifying the Vapor Phase One. So first, a few organisational items and upcoming milestones.

Design for manufacturing

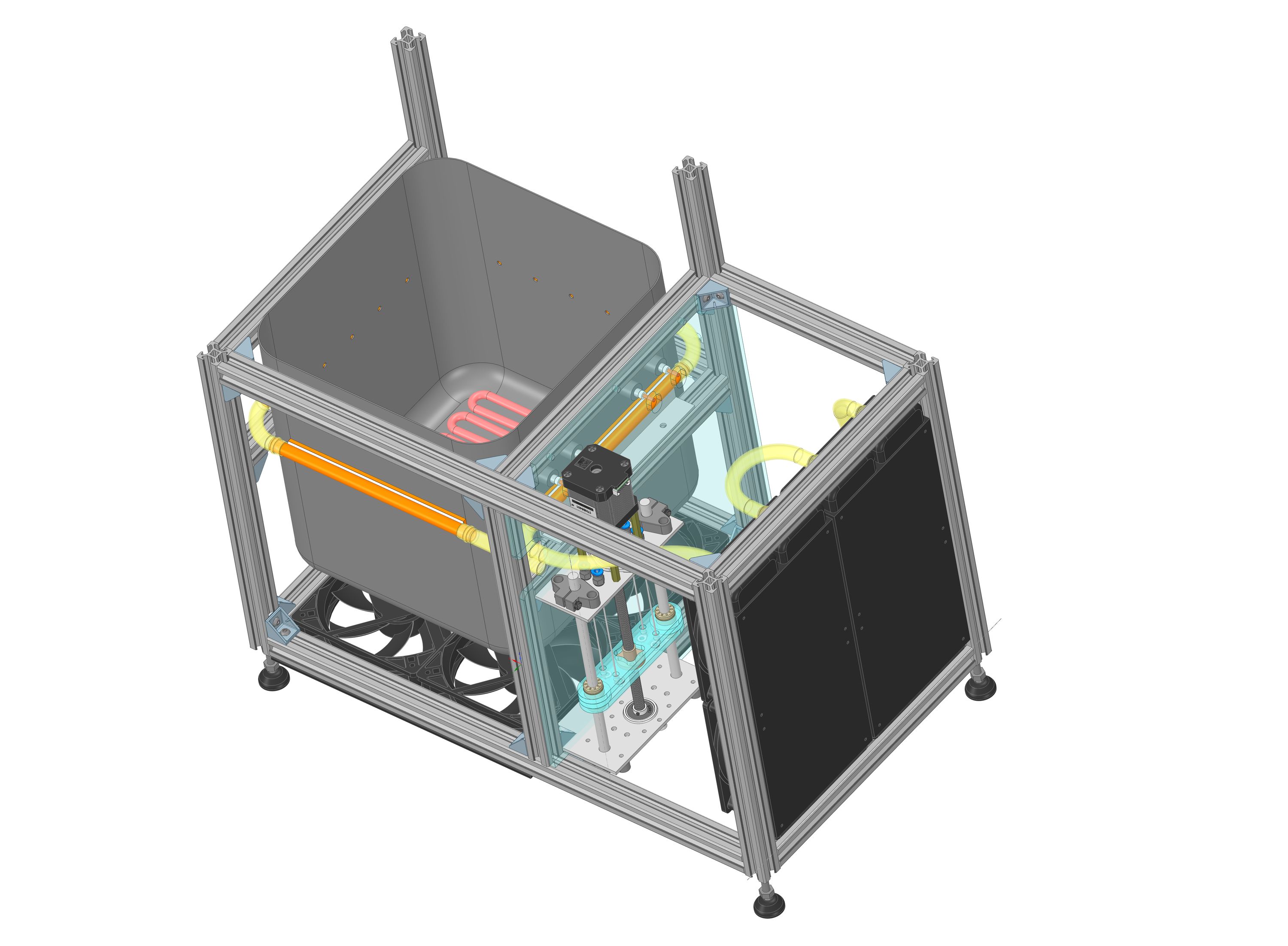

We are now working on getting our current prototype ready for production. This means selecting reliable suppliers, optimising production processes, and revising and optimising critical components of the Vapor Phase One. We have set a goal of completing these tasks by the end of this year. This will also change the design a bit, but we are working to ensure it will look as good or better than the current version.

Certifications

After the holidays, in December of this year, we are off to a certification institute. While there, we’ll carry out extensive tests and measurements to ensure the final prototype conforms to all the relevant international standards.

Now, here’s a look at some technical design details under developmet:

We are currently working on optimising our cooling system design. Our current concept works very reliably, but has a few potential weak points we want to eliminate. We use aluminium cooling blocks which have a cooling fluid flowing through them to ensure the necessary heat dissipation. The cooling fluid is distilled water mixed with corrosion inhibitors. Inhibitors are necessary because there are brass components in the cooling circuit. The surface areas are very small at the moment, so electrochemical corrosion is not a major problem. Nevertheless, we want to provide a very durable solution, so we are working on removing all aluminium components from the cooling loop. Here’s what that development work looks like:

Easy installation of the cooling blocks is also an important point to consider. In the current solution, two mounting plates and six screws are required to mount one of the four cooling blocks in the process chamber. This costs time and complicates replacement or upgrade of the components. So we decided to design a solution using copper tubes soldered to a thick copper sheet. This solution offers sufficient cooling capacity, prevents electrochemical corrosion as no metals with corrosion potentials are used in the cooling circuit, and the solution is easy to install. We have numerically tested this design extensively using FEM simulations and will now implement it for testing. We will publish the test results here with comparisons to the simulation data. A visualisation of the simulation is available on our Twitter Channel.

Thanks again for your support! We will keep you up to date!