Project update 10 of 13

Getting Pocket Reform Ready to Ship

by MNT ResearchDear Pocket Reform supporters,

We have exciting news for you: Pocket Reform assembly is well underway! In this update, we give you a detailed insight into our progress, the reasons for the delays—and an estimated shipping date. So let’s dive right in!

What exactly has been assembled and sourced so far?

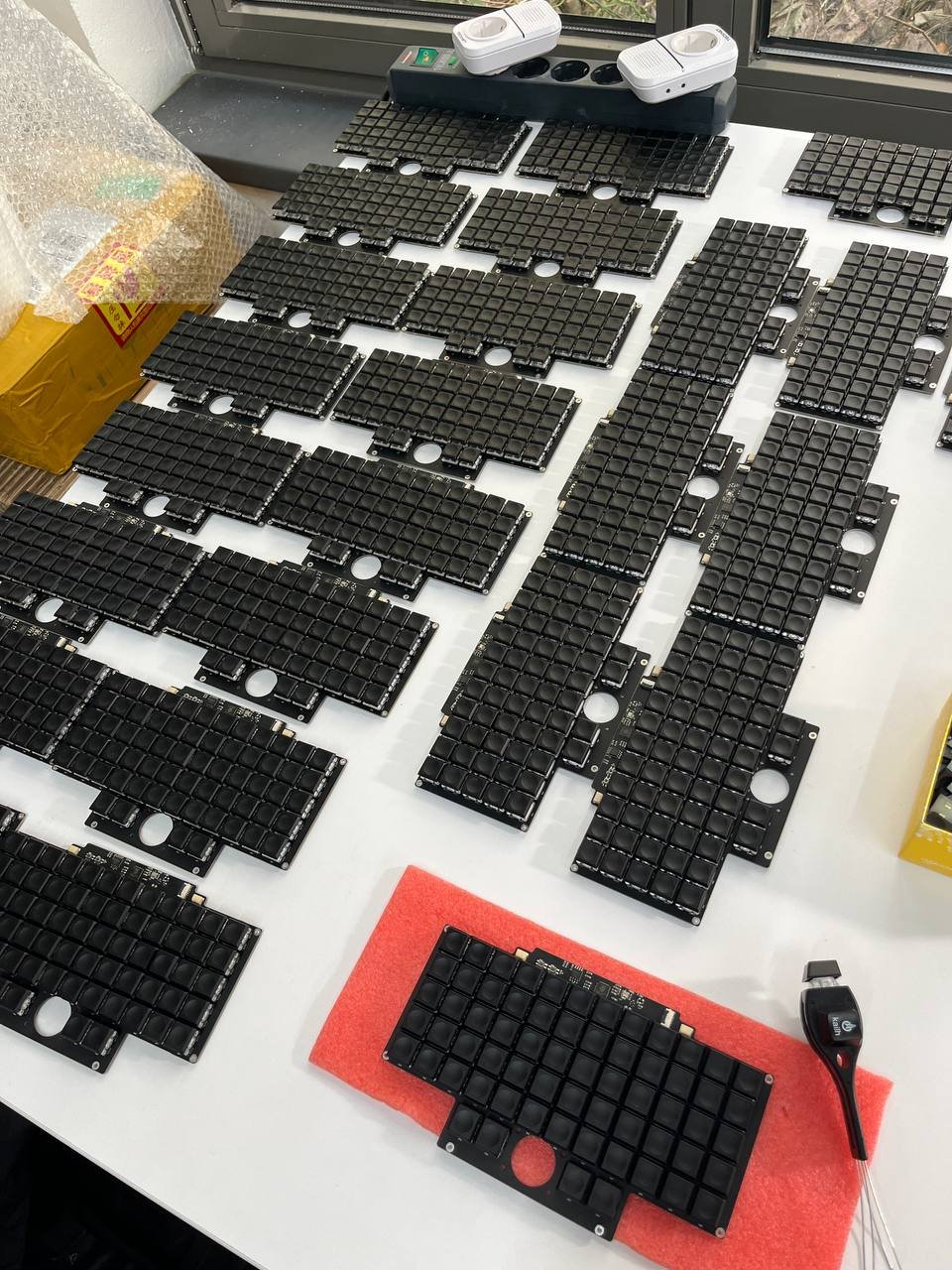

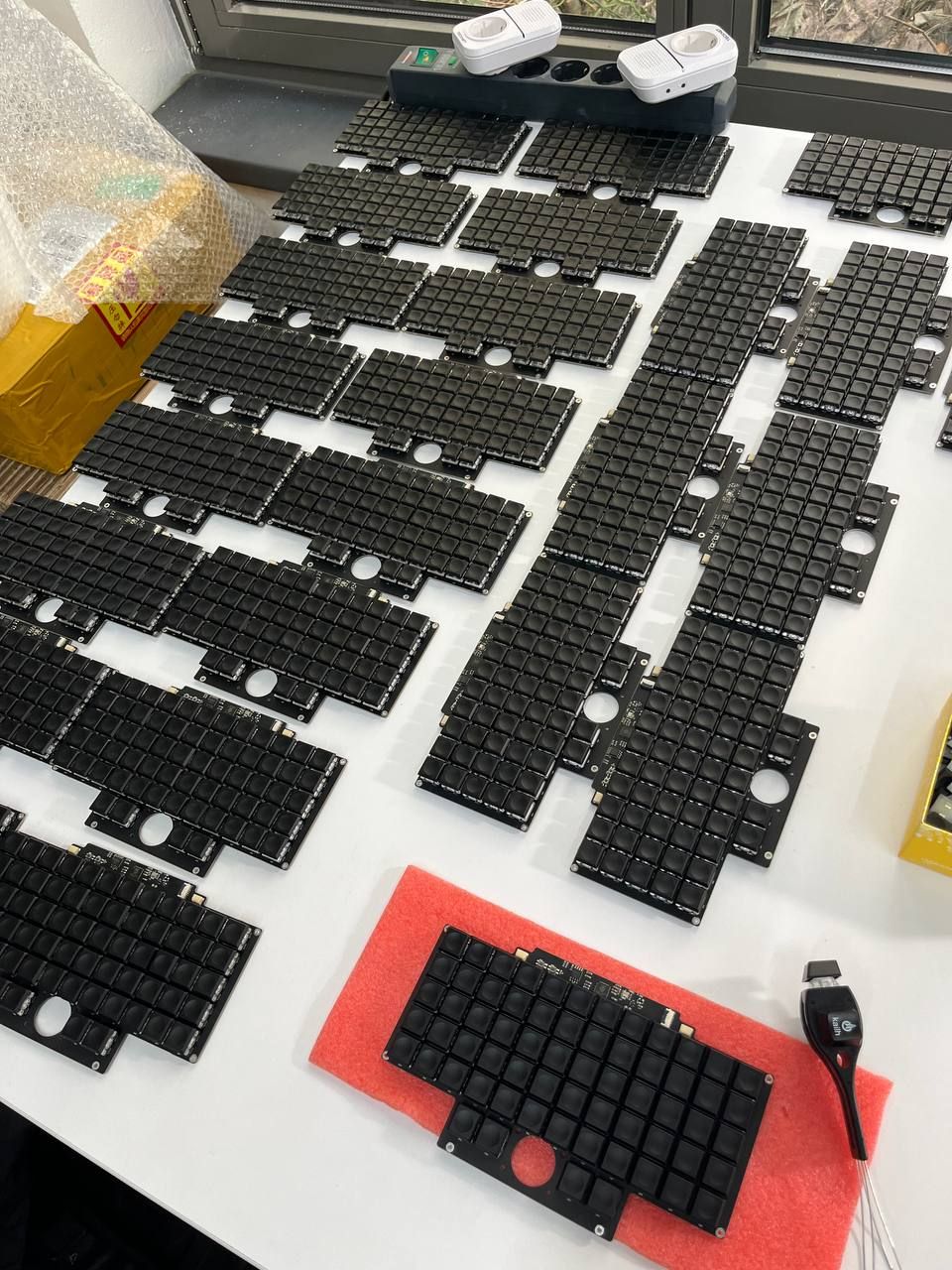

The assembly of Pocket Reform has been underway for almost three weeks. Here is what we have been able to achieve so far: All of the keycaps and keyboards have arrived and are working perfectly, so we are now plugging keycaps onto keyboards. A total of 48,000 caps have to be plugged in (750 × 64). This is a very tedious task, but we are making good progress.

We think we will have 200-300 keyboards ready by the time this article is published. However, they still need to be laser-engraved, which we also do on site. This takes about 5-10 minutes per keyboard.

Ribbon cables were plugged into trackball sensors and OLED displays (for status indication).

All the electronic components have been sourced and the PCBs are almost assembled at PCBWay. (Shoutout and a big thank you for sponsoring us with coupons!) Everything will be ready after Lunar New Year.

We had a bit of a struggle to tune everything right with the screws (countersinks), but PCBBuy helped us a lot to solve this.

As for sourcing, all of the SSDs (for the Hyper pledge level) are now in stock as well as the (specially made for us) i.MX8MPlus CPU modules with 8 GB RAM and 128 GB eMMC. We have already tested some samples and they work just fine. The hinges (which are fancy black nowadays) and the flat PCB case parts are also in stock now. They look great, are of good quality and fit well, so that’s a relief!

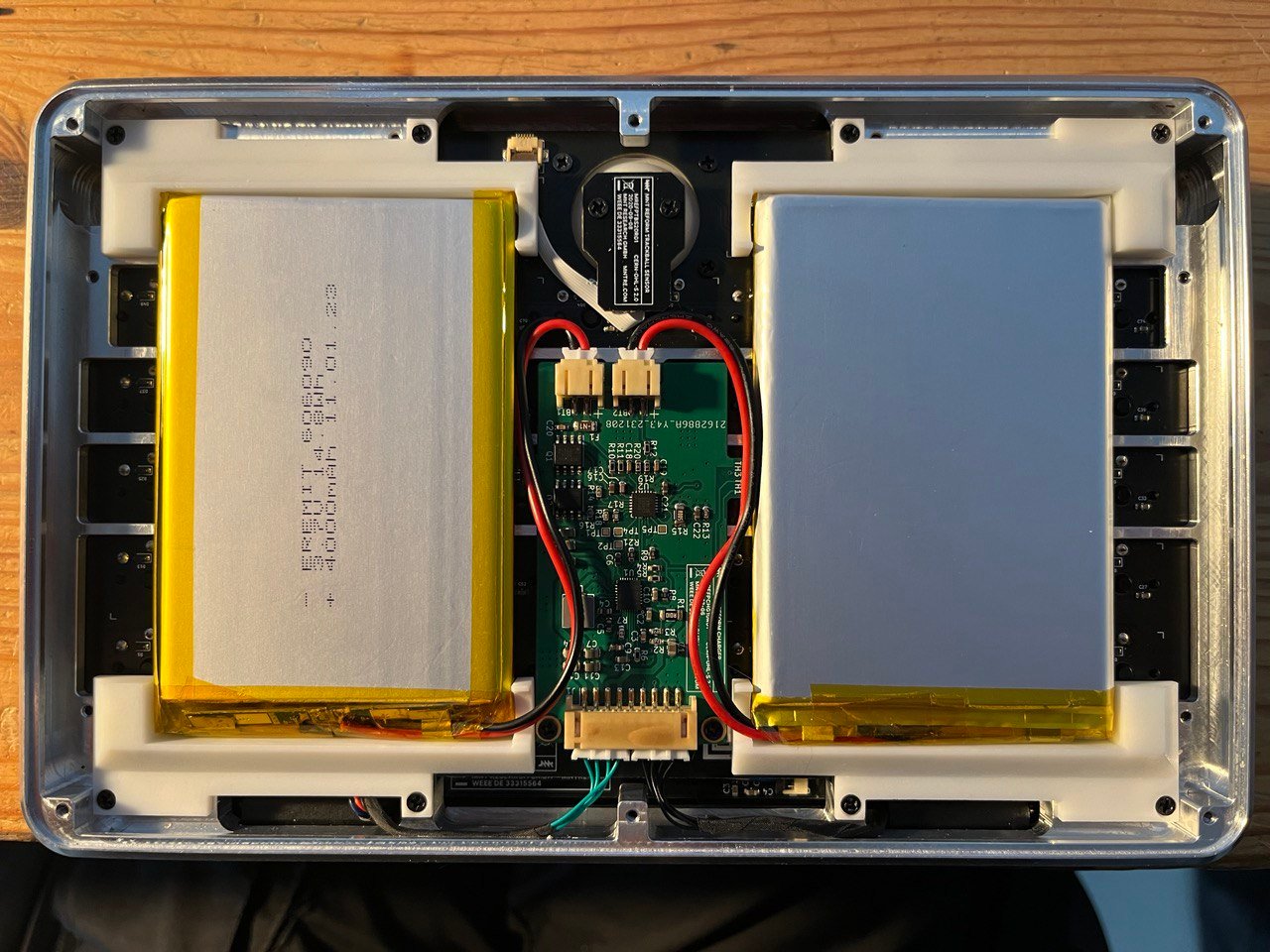

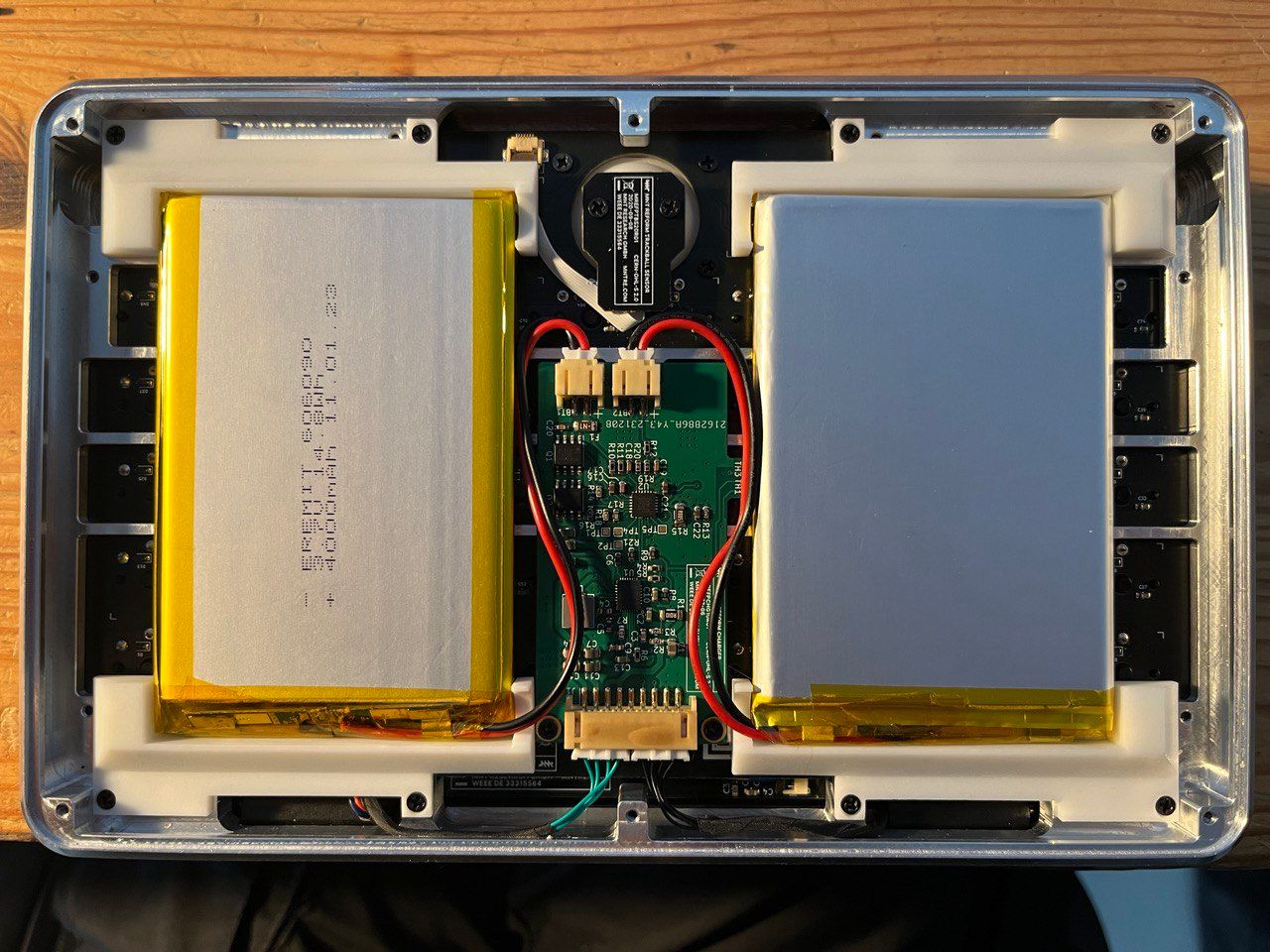

Small but important parts such as batteries, magnets and screws are also in stock.

What are the next steps?

Regarding sleeve production, we have decided to outsource this as we don’t have the resources to do this in-house. We have found a Chinese company to sew all the sleeves for the "hyper" orders, and we went to great lengths to create technical plans for the sleeves and make sure the quality is up to our standards. The Piñatex fabric is now in stock and will be sent from Germany to China for production.

As for in-house assembly, the next steps will the engraving of the keyboards and the complete assembly of keyboard and trackball units. The 3D-printed battery holder will be mounted in the lower half of the device.

Hinges and cables will be installed to connect the two halves.

The CPU modules will be plugged into the motherboards and flashed with firmware and software.

After all this is done, final assembly with other parts, displays, bezels and batteries will take place. This will be followed by full QA testing.

The final step will be packaging.

What are the reasons for the delays?

We have faced some major difficulties while sourcing certain parts.

For example, only 60 (out of a total of 750) CNC cases were sent to us before Lunar New Year, but have been damaged due to poor packaging.

It is still unclear whether we will be able to save a few of them. We will make sure that the remaining parts are properly packed to prevent damage during transport. The quality of the CNC parts was otherwise perfect, so this shouldn’t be an issue in the future.

The 3D printed parts have arrived and look great, but on the trackball cups the indentations for the steel bearings are a little too big (only minimally, about 0.1/0.2 mm, but it makes a huge difference). With our in house SLA prints, everything was fine. However, the process at JLCPCB is slightly different, so the accuracy is different. As a result, the ball drags on the bottom of the cup. We are now immediately doing a test series where we order about 50 pieces, each with slightly different radii, so there will be something of use. Once this proves successful, we’ll order them again in bulk. It should take a maximum of two weeks for the new mass-produced goods to arrive. Fortunately, the cost of this part is quite low, so it’s not a big issue for us.

Another problem occurred with our cable manufacturer: Contrary to what was announced, they only sent us samples before Lunar New Year. These are great, but mass production of the cables won’t start until next week.

We have sourced displays from various sources, and one main source has sent us a box of almost 100 bad displays. We still have about 250 good displays from other sources (all of them are already QA tested). We’ll source the rest from various other sources where we always order samples first which we test. Only after successful testing, we will order more from the same source. The display is EOL (end of life), so we have to do it this way. Fortunately, we have found a new display that is a drop-in in terms of specs, but needs additional driver development and technical integration that we will carry out in the next weeks.

Estimated Shipping Dates

The "non-hyper units" will be assembled until all parts for the "hyper units" are available.

Parts of the "hyper" pledge level include the sleeve, a printed and signed copy of the handbook and a double-sided, multicolor Risograph print poster with the Pocket Reform illustration and the schematics. We will have all this ready by April 2024.

We estimate that the first delivery for non-Hyper orders to Crowd Supply/Mouser will be towards the end of March 2024. Hyper orders will mostly likely be fulfilled in May 2024.

Thank you so much for bearing with us, and we can’t wait to ship your orders!

Your MNT Research team