Project update 10 of 19

Wrapping Up Pre-Production

by Jacqueline LG’day!

Before we get into the meat of the update, anyone attending Crowd Supply’s Teardown this weekend should be aware that we’ve sent over one of our latest pre-production units! If you’re planning on attending, then make sure you check it out!

We’re now about halfway through the time we budgeted for our first batch of units. Ideally, we had hoped that by now we would be wrapping up our pre-production work, and shifting our focus to our first full production batch. This is more or less the state of things.

Pre-Production units

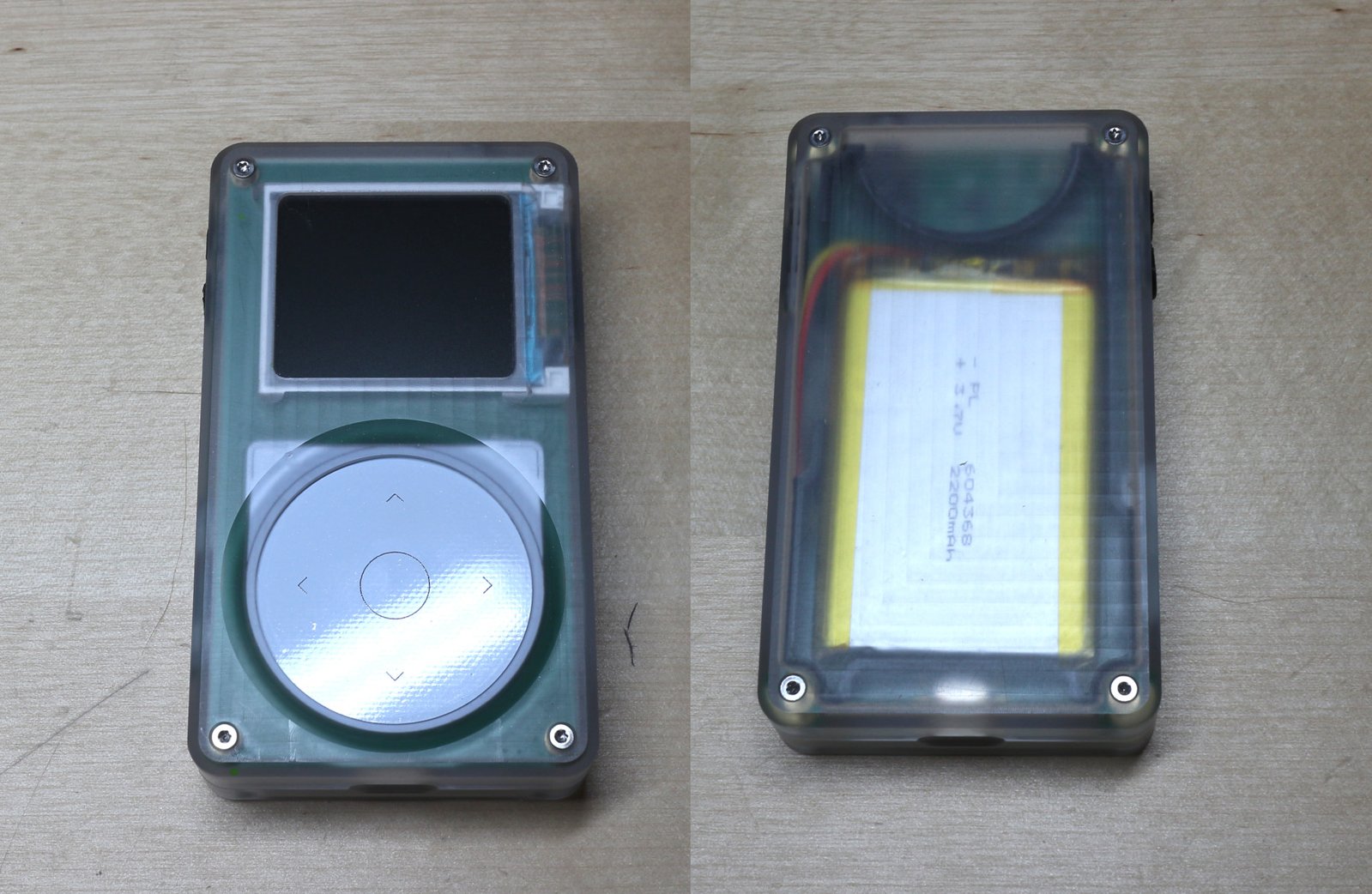

Shortly after our last campaign update, we received a small batch of pre-production cases. This means we now have a small number of units assembled completely with production-quality parts!

(Note the finish is not representative; visible tool marks are very cool, but we will endeavour to avoid them on our production units!)

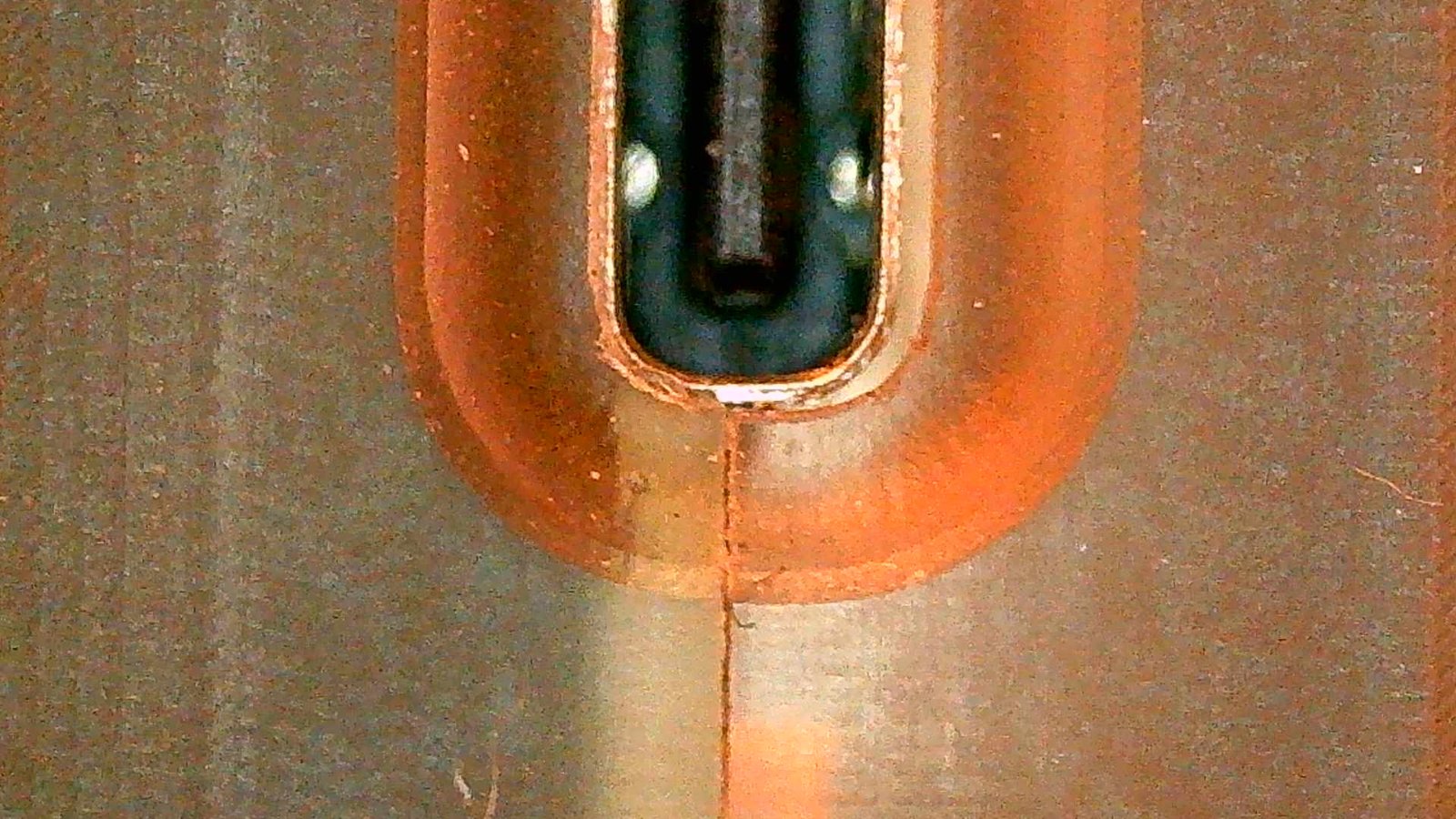

We are generally happy with this small batch. However, the final assembly of our production parts revealed a few small issues with fit that we are going to resolve before full production. For example, here is an inspection image of Tangara’s USB-C port:

The small gap on the right is present because the case cutout for the port is misaligned by 0.32 mm. This misalignment is ultimately due to differences between our prototype hand-assembled PCBs, and our production machine-assembled PCBs. We noticed a few issues in this vein, corrected them, and we are now preparing for a second small pre-production batch of cases.

As our work on the case was running behind even before this, there is a risk that needing to do another pre-production batch of cases will delay delivery to backers by a few weeks. It’s too early to be certain, however; we’ll let you know when we know.

Aside from this, we have now gotten enough validation of our component and supplier choices that we are actively ordering and storing production quantities for most of Tangara’s parts.

Preparing for scale

As we approach the transition from pre-production to production, we’ve also been beginning work on improving our device assembly and testing processes. As it stands, I can assemble about half a dozen devices by hand over the course of a couple of hours. This is good enough for pre-production, but would be a miserable pace at scale.

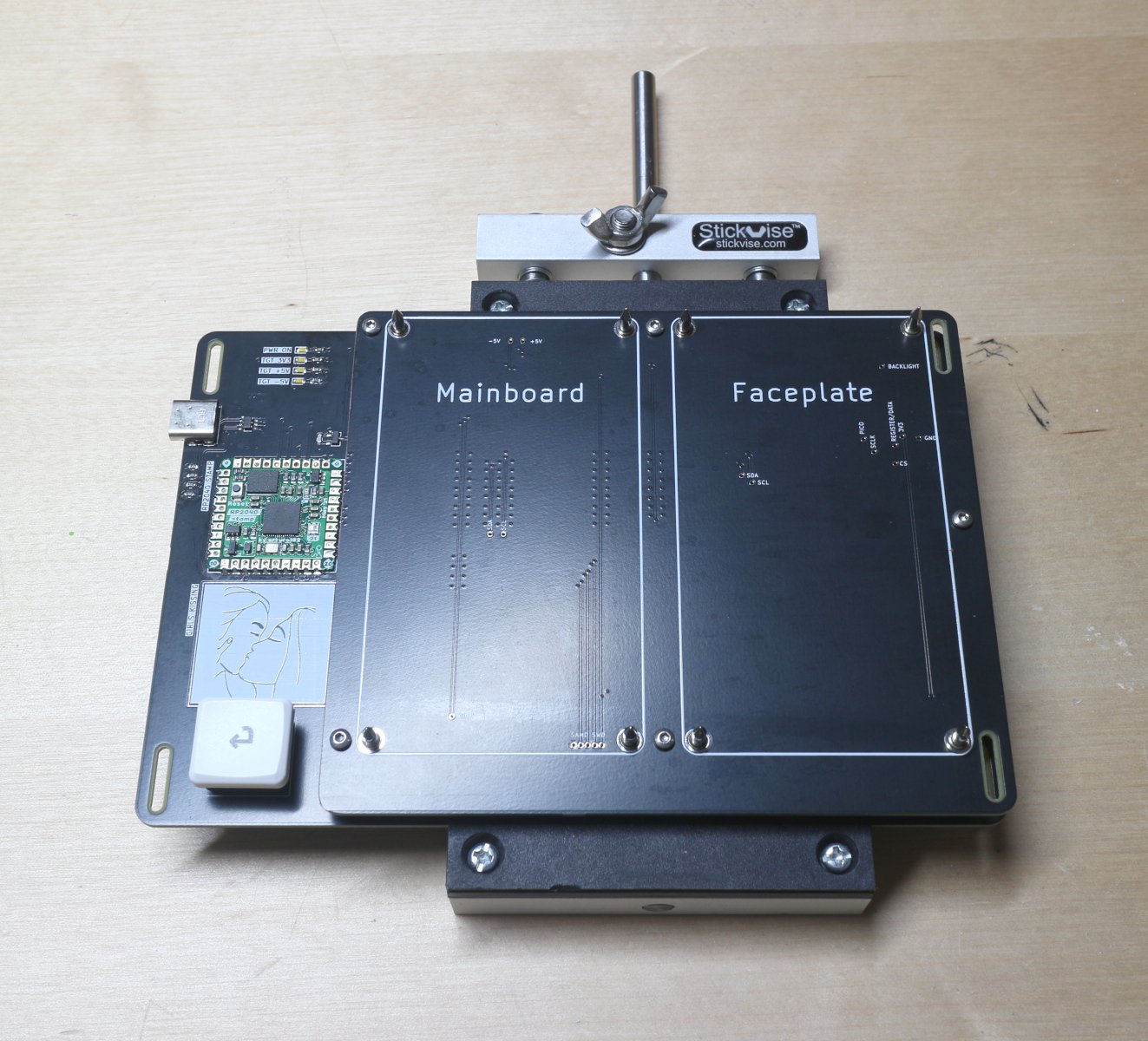

To improve assembly speed, we’ve been working on a small assembly jig that can hold PCBs in place for assembly, whilst also running electrical tests, and flashing each device’s firmware.

Certification and compliance

With a small run of cases produced, we’ve been able to fully assemble a set of sample units to send off for formal CE and FCC testing.

These units have already been received and bench tested by the testing lab, and early signs look extremely good. The next step here on our side is to collate an enormous amount of paperwork in order to produce formal testing documentation. There’s not a lot of risk involved with this work, but it is quite time consuming. With luck, it will be done by next month.

Firmware progress

As I mentioned last month, we’re getting in the habit of announcing our firmware progress on Codeberg instead of in campaign updates. We may still talk about particularly exciting updates here, however!

Speaking of exciting firmware updates, this month Daniel implemented support for handling actions (e.g. play/pause/skip track) sent by Bluetooth devices such as headphones and speakers.

That’s all for now!

Thanks again to all of you for your support. It’s a lot of hard work to build a device like this, and we can’t wait to get Tangara produced and in your hands.