Project update 11 of 19

Clearer Cases and a Production Update

by Jacqueline LHello again! Welcome back to another exciting Tangara campaign update.

This month, we’re beginning to get into manufacturing our first full batch of production units. These will go towards fulfilling all orders placed during our campaign. We’d also like to talk about a change to the production finish of Tangara’s case.

Case Manufacturing Update

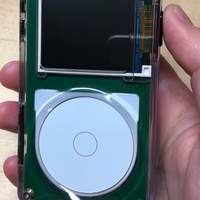

We have received a sample order of cases with fittings from our production CNC manufacturer. We have a lot to say about them! But first, some photos:

You may be wondering why there are two different finishes in these pictures. After our last update, in which we showed off a run of cheap, unfinished cases, we received some pretty strong feedback from people who thought a more transparent finish was more appealing than our planned bead blasted finish. So for this sample order, we asked for a mix of some polished cases and some bead blasted cases.

(If you’re wondering why the touchwheels look different between the two units, it’s because our production touchwheel covers are double-sided. You can flip it over to get the other design if you want.)

Let’s talk about the bead blasted case first; this was the finish we originally intended to use for our production batches. The samples we received are pretty good, but they’re a little less transparent than we were aiming for and the feel of the assembled device in the hand is a little bit rougher than we’d like. In order to improve on these aspects, we would need to consider yet another round of case samples, using a variety of different grits so that we could fine tune the exact finish. This would be an expensive and time consuming process, but we could certainly get to a point that we’re happy with.

The polished finish, on the other hand, has absolutely stunned us. When we were first planning our campaign, our expectation was that a finish like this would only be achievable through either a high setup-cost injection moulding process, or through expensive finishing steps.

There are obviously some trade-offs involved with either finish (e.g., we worry a bit about scratches on the polished cases), but all in all we’re much more confident proceeding with the polished finish shown here for our production units. Barring some major issue discovered with the polished case over the next couple of weeks, we intend to continue with it for full production.

Fittings

Tangara’s ‘fittings’ are the SD card cover, buttons, and switch. Up until now, we’ve been working with 3D printed fittings, as many of the cheaper, prototype-scale, CNC manufacturers have minimum part sizes larger than our fittings. These 3D printed fittings have been good enough, but 3D printed parts obviously have very different materials and properties.

Our production fittings are CNC machined from aluminium, with hard-coat anodization. They look and feel wonderful, and should be very durable against wear.

We’re very happy with the quality of these fittings. The only note we’ve got from this run is that the buttons and switch both rattle about a little within their slots in the case. This is due to some overly-cautious clearances in our design. We’ll be doing a quick-turnaround iteration on these parts before proceeding to production.

EMC Testing Update

EMC testing on Tangara has finally been completed! We passed! This is a really great achievement for our little team of elevated hobbyists, as formal testing can reveal issues with even very robust, professionally designed devices.

There is still some work to be done to formalise this result. Our testing lab is still in the process of finalising their testing documentation, and we’re also going back and forth to make sure our user manual language and device labelling is what it needs to be to avoid regulatory issues.

First Production PCBA Batch Underway

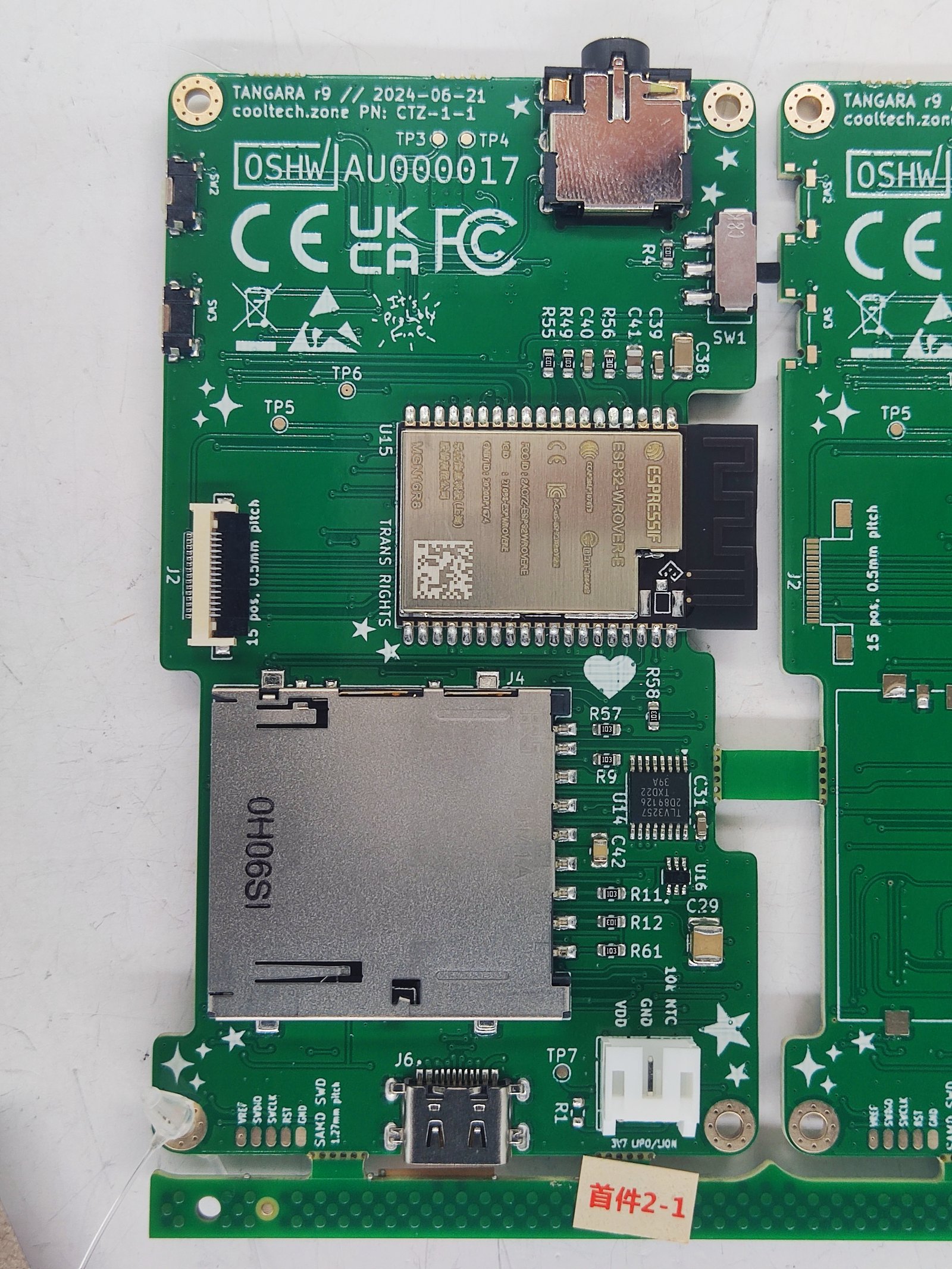

With positive feedback from our EMC lab, we’ve been able to kick off our first batch of production PCBs. This has been proceeding well! We even have a photo of some of the assembly work to show off already:

This photo is more or less the same as our previous PCB assembly images, which is a good thing!

That’s All for Now!

It’s been a very busy month for us and things are likely to be even busier next time. We hope you’ve enjoyed reading this update. Until next time, take care!