Project update 37 of 38

How to Synchronize Multiple StereoPi?

by Eugene PomazovWhy?

You may ask, "Why do I need to use multiple StereoPi at once?"

Well, we got a set of requests from some customers who needed to take a lot of images at once. One of the most popular use cases is the creation of animated "3D" GIFs. These images are created using a set of images (usually 4). In our article we are describing all processes, starting from capturing files and up to creating MP4 video files. So you can post it as a video, or use a video->gif converter to get an animated image.

The second popular use case is a 3D reconstruction, using a set of cameras. For example, through the use of Multi-View 3D Digital Image Correlation (Multi-DIC), a technique recently published by Dr Dana Solav and Dr Kevin Moerman.

DIC allows the researchers to capture both the 3D shape and the 3D deformation of the objects imaged. Their application is imaging of the lower limb with the aim of automated design of prosthetic devices.

Their initial work featured a circular array of 12 Raspberry pi systems with cameras. However, true synchronous imaging and triggering of the separate cameras proved very challenging, and the lack of proper triggering is limiting the application to relatively slow movements.

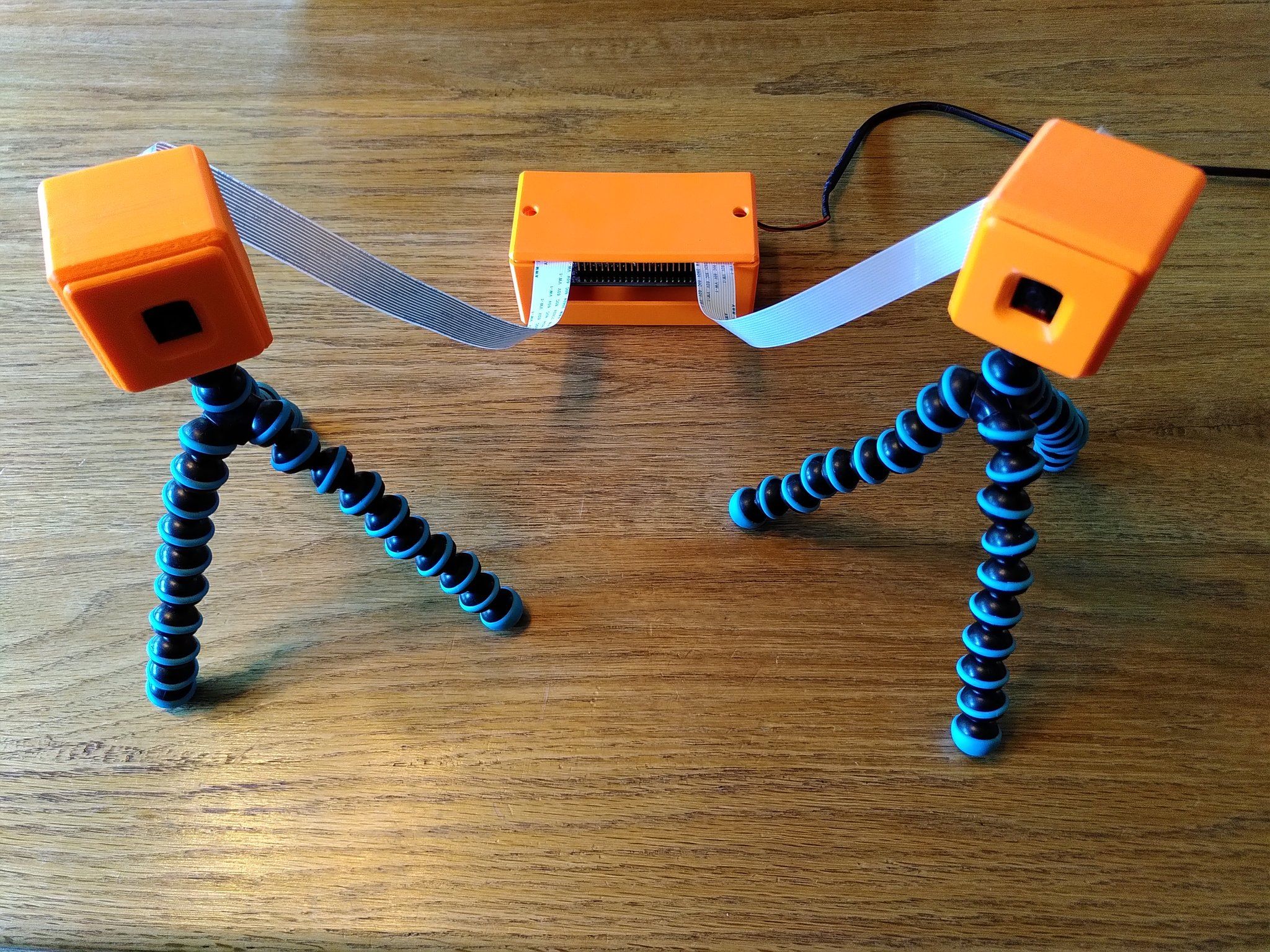

Since StereoPi systems can naturally acquire images simultaneously from two cameras, Dr. Kevin Moerman is now exploring the use of this simple StereoPi setup for 2-camera DIC:

Through the use of the StereoPi system they can now achieve synchronized imaging and simplify their set-up significantly. The two camera DIC setup will enable low cost deformation and strain imaging, e.g. for imaging tensile testing of materials. You can find more details in Dr. Kevin Moerman’s post on our forum here. In the future they aim to use a circular set-up featuring multiple StereoPi systems to achieve full 360 degree shape and deformation imaging, and will require simultaneous triggering.

How?

If you are interested in this synchronization approach, you can find our detailed how-to guide here on our blog.

Stay tuned and happy making!