Project update 18 of 20

Moving PCB Vendors

When you deliver a new PCB design to a factory, they must perform Non-Recurring Engineering (NRE) work in order to validate the design and convert it from the source gerber files into commands their machines can use. They also need to program the machine to do a full electrical test of the board once it’s produced. This can cost a lot of time and money.

It was not a light decision to switch factories, but we did anyway. The new factory started the process to produce new Fomu PCBs, and we hope to take first delivery of these bare PCBs this week. Producing Fomu is not easy, and we’re confident the new PCB vendor will rise to the challenge.

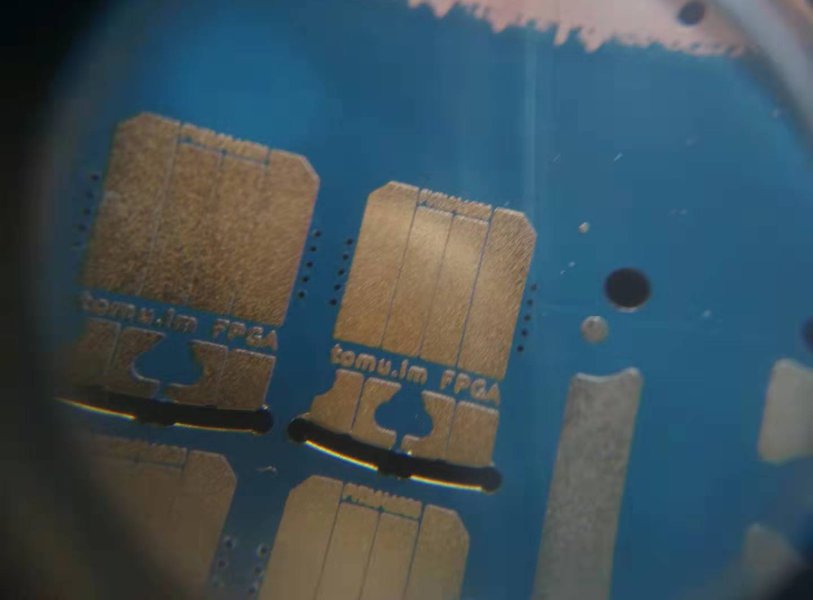

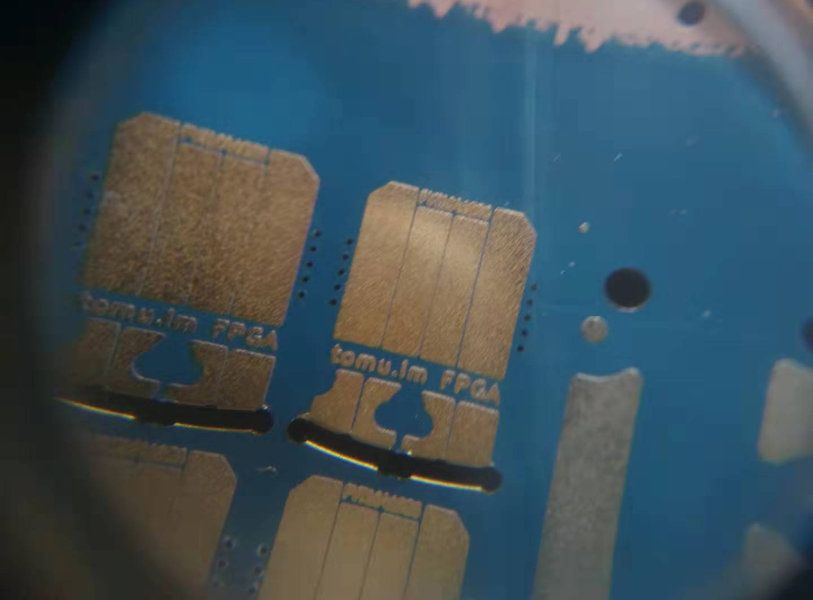

They have already had to scrap one batch of PCBs. However, unlike the previous vendor, they owed up to the mistake, explained the root cause (including photos), shared with us their plan to solve the issue, and are quickly working to rectify the problem. The root cause was the USB pads were larger than most hard gold projects they’ve dealt with, which resulted in an over-plating of gold onto the pads. They will adjust the current used during the plating process and try again this week.

Physics is hard, but frequently it’s repeatable. Once they get a method working, we should have a steady stream of boards available to produce working Fomu units. And as soon as that happens, we’ll send an update letting you know that production is back on track.