Project update 12 of 20

Mass Production and Teardown

Mass Production has Started!

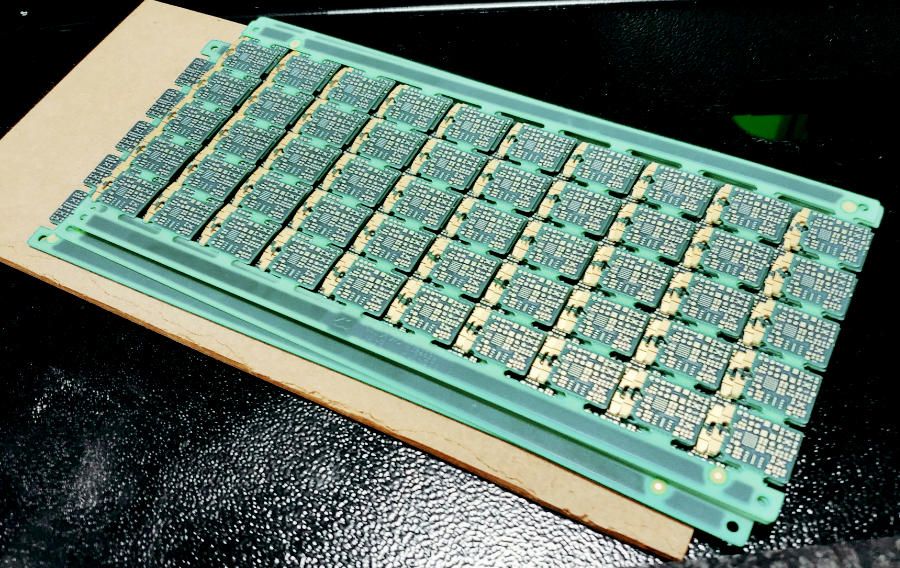

We went to China last week to help begin mass production ("MP"). Ordinarily you do a small prototype run, then check that the product coming off the line is good. We decided to speed up this process a bit by showing up to the factory line and having them run a single panel of Fomus in the morning, then running the factory test on them. If things went well, we’d green-light production and all of the boards would get assembled.

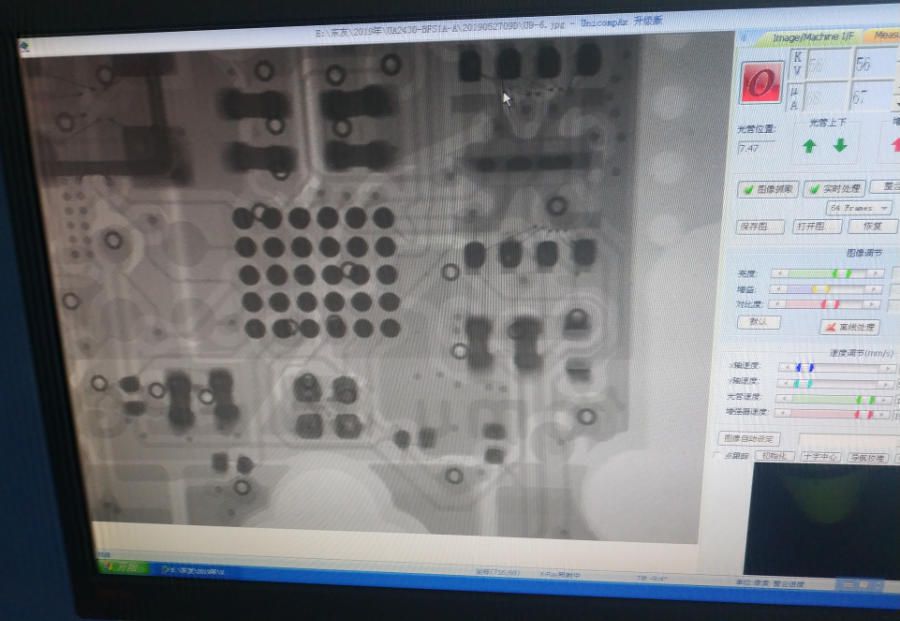

Fomu’s FPGA is a very small chip that is connected via an array of balls sitting underneath the chip. The best way to make sure those balls are correctly soldered is to use an X-ray machine, which a good SMT assembly shop will have access to. We took a few Fomus and put them in the X-ray to check their connection, and everything looked really good. And the pictures came out really well!

Remaining Tasks

While it’s true that the PCBs are finished now, we’re not quite done building Fomu. We still need to finish the plastic cases, and we still need to package it up and ship it to Crowd Supply in Portland. Also, Fomu will only come with a basic USB-DFU bootloader installed just like Tomu.

Now that the hardware is mostly finished, we can turn our attention to software and tooling. We’re still working on an advanced bootloader that presents itself as a USB disk drive, and we have a bunch of software and firmware tools we’re working on to help you get started quickly.

Fomu at Teardown

This month Fomu is once more returning to Portland to attend Teardown. If you’re in town, stop by and say hello!

As always, thanks for supporting us and backing Fomu!

— Sean "xobs" Cross