Project update 14 of 20

Finishing Touches

We’ve updated the plastic case, loaded Foboot v1.8.6 onto production units, and started work on what will become the Fomu software stack. We’re not shipping yet, but we hope to be very soon!

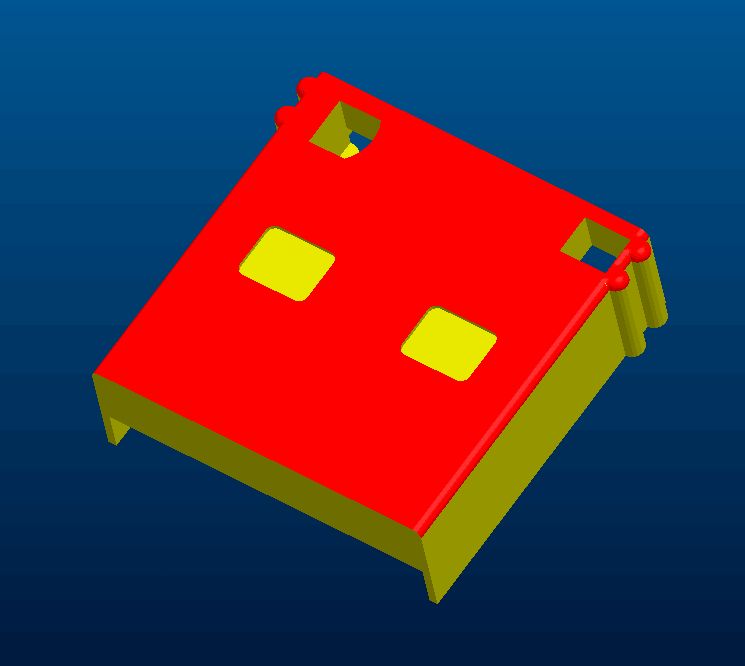

Case Modifications

As part of testing the final production version, we discovered that some USB ports didn’t work with the Fomu case, or didn’t make good contact and could reset the board if you touched it. This isn’t a very good user experience for a board whose primary means of interaction is touchpads!

We showed this issue to the plastics factory, and they came back with a simple solution: make the case 0.1 mm thicker. This is good for two reasons: First, making a plastic piece thicker is easier than making it thinner, because you simply need to scrape away more steel from the tool. Second, it means we can add alignment holes to make sure the case stays put.

We’re now building new cases for the units we will ship, and everyone will have a much more reliable Fomu as a result.

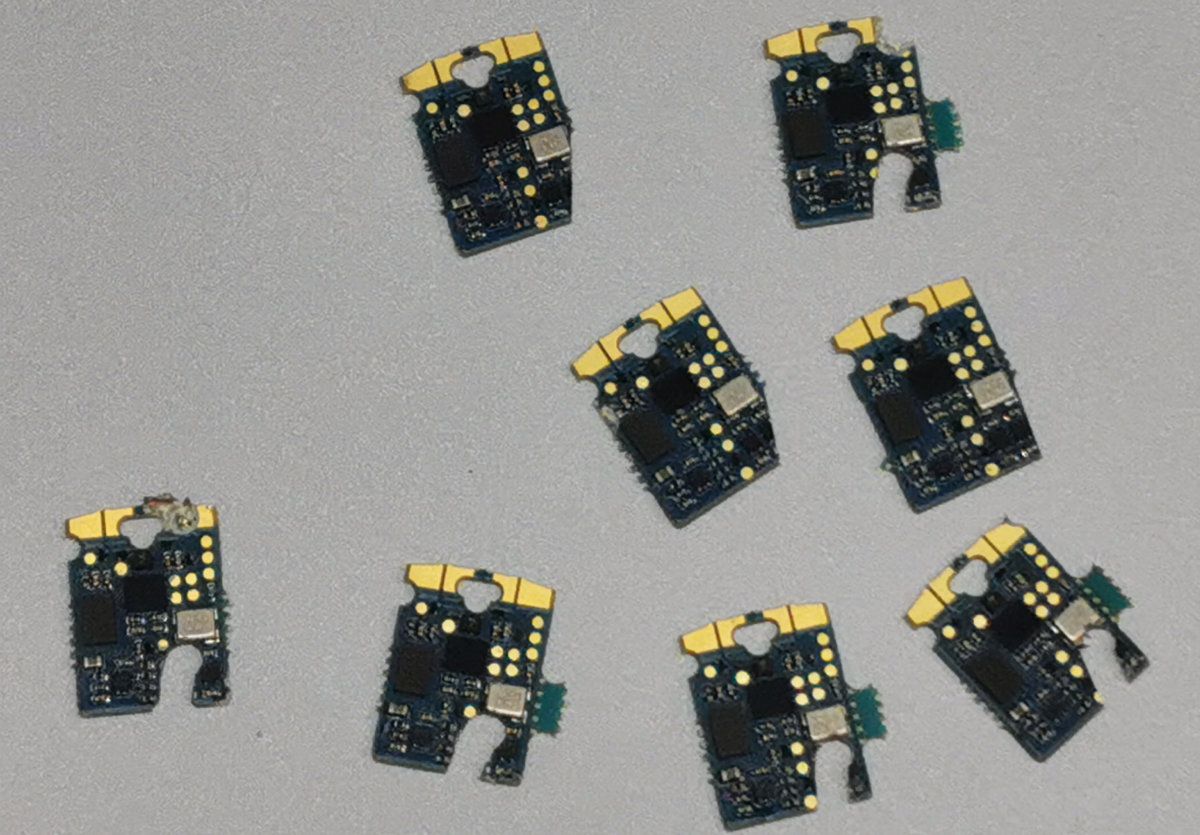

Erase Tool in Real Life

If you remember from the mass production announcement, Fomu is produced on panels. This is an extremely common method. Normally panels are separated with a saw, however the factory felt the thin PCB might have problems with a saw, so they produced a jig and used a CNC drill to separate the boards after production.

Unfortunately some Fomu boards got caught on the drill bit and went flying, leading to an effect that looks like someone used the "erase" tool in real life. Such scrap is not unheard of during initial runs, and the factory has learned how to control the de-panelization process better.

Remaining Tasks

Now all that’s left to do is to finish up the rest of the boards, finish re-making the plastic cases, and delivering everything to you. Once production is finished, we can resume work on the Fomu software stack to add improvements for things like more USB endpoints, hardware multiply support, and an easier-to-use bootloader. We’re looking forward to seeing what you do with an FPGA in your USB port!