Hello everyone! We are happy to announce our Vapor Phase One is continually improving with the incorporated feedback of our customers. We are currently producing the second batch, which has been redesigned and we’re ready to solder your PCBs.

But the redesigns are not only in the hardware. There will be a software update available by end of May that can be applied to every Vapor Phase One. In the following we quickly go through the main aspects:

1. More flexibility in temperature profiles and usage of Galden©

Different types of Galden© are compatible now. The type of process medium that is used determines the highest temperature that can be reached within the temperature profile, and therefore also in the soldering process itself. We will now support more types of Galden© to allow more flexibility in terms of temperature profiles and the solder medium. Until now, process medium with a boiling temperature of 230°C was required. With the update, you can now use Galden© with a boiling temperature between 100°C and 250°C.

Via “Boiling Temperature” the desired Galden© temperature can be set. The incorporated microprocessor evaluates the given temperature profile, and uses the boiling temperature for setting the heater. Meanwhile, the default setting for the boiling temperature remains set to 230°C. Further, the anti-condensation temperature can now be selected manually. If no specific temperature is selected, the “Anti-condensation” mode will be skipped, and the lift will go straight up.

| ### VPO | |

| Name | Custom |

| Boiling Temperature | 200 |

| ACT | 110 |

| ### Profile | |

| Absolute Time in S | Temp |

| 0 | 95 |

| 80 | 95 |

| 120 | 120 |

| 200 | 140 |

| 240 | 180 |

| 280 | 190 |

| 320 | 200 |

| 350 | 200 |

| 380 | 120 |

| 400 | 0 |

2. More transparent soldering process

While the Vapor Phase One is on, you can now easily see which status it is in. This makes the process much more transparent and understandable. The current status is checked and disclosed every second to the user via the display. The status can be found under the new “i” (information) symbol.

The statuses are:

- Calibrating

- Idle

- Preheat

- Soldering

- Quick Cool

The latest User Interface includes the “i” symbol for additional information about the current status of the VPO.

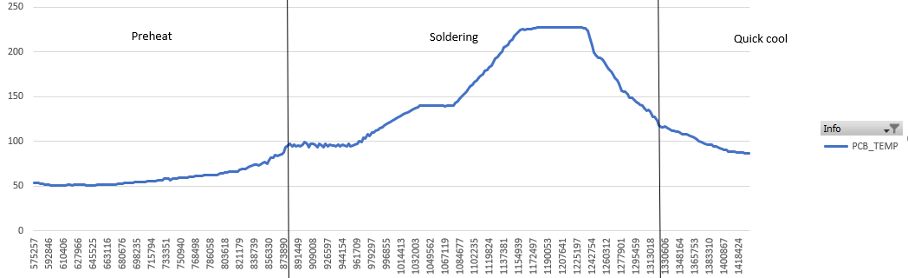

Examplary temperature profile with the the corresponding status reports.

3. Improved control technology

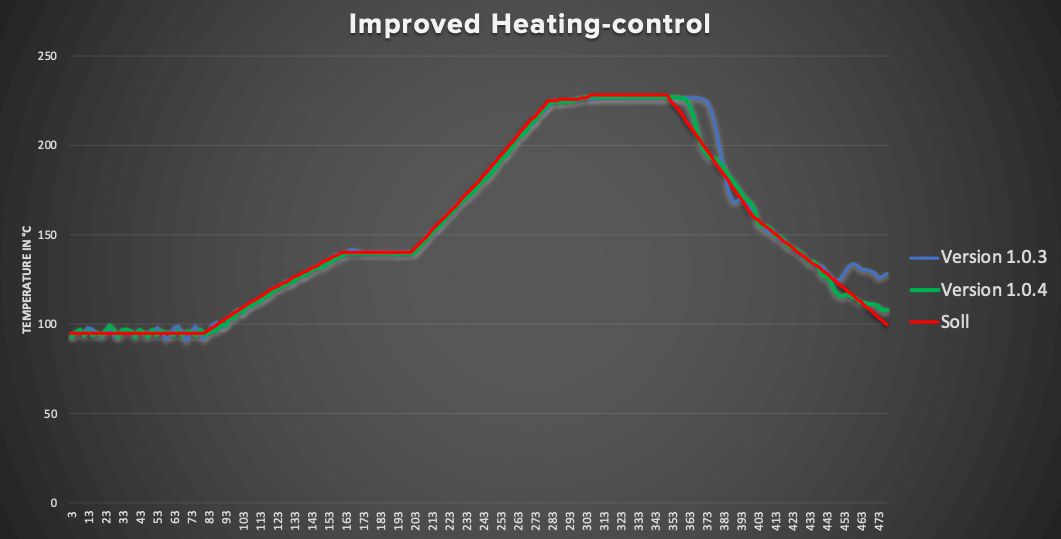

We continuously improve our control technology. With the new update, a maximum temperature deviation of +/-3 °C compared to the temperature profile is realized. The heating control is now switched off during the soldering process. This regulation caused higher oscillations in the past. The temperature is now controlled exclusively via the lift, which is following the target temperature using a PID-Controller, to reduce Oscillation.

Control improvement: The red line is the temperature that should be reached. The blue line shows the actual temperature with the previous software version. The green line shows the actual temperature that is reached in the process after the latest software-update.

We will keep you updated about our process of learning and improving the Vapor Phase One in cooperation with our customers and own experiences. Stay tuned! With best regards from Germany,

Your PCB Arts Team