Project update 6 of 7

Manufacturing Status

by Kai GLet’s start this update with some good news: We’ve received the funds from the campaign and manufacturing is in full swing.

Here’s the current status of the individual products:

- Riotee Module: PCBs arrived, components arrived, assembly pending

- Riotee Board: PCBs arrived, components arrived, assembly pending

- Riotee Probe: PCBs arrived, components arrived, assembly pending

- Riotee Solar Shield: Assembly completed, depanelization and testing pending

- Riotee Capacitor Shield: SMD assembly done, THT assembly pending

- Riotee Sensor Shield: Manufacturing completed, ready for shipping

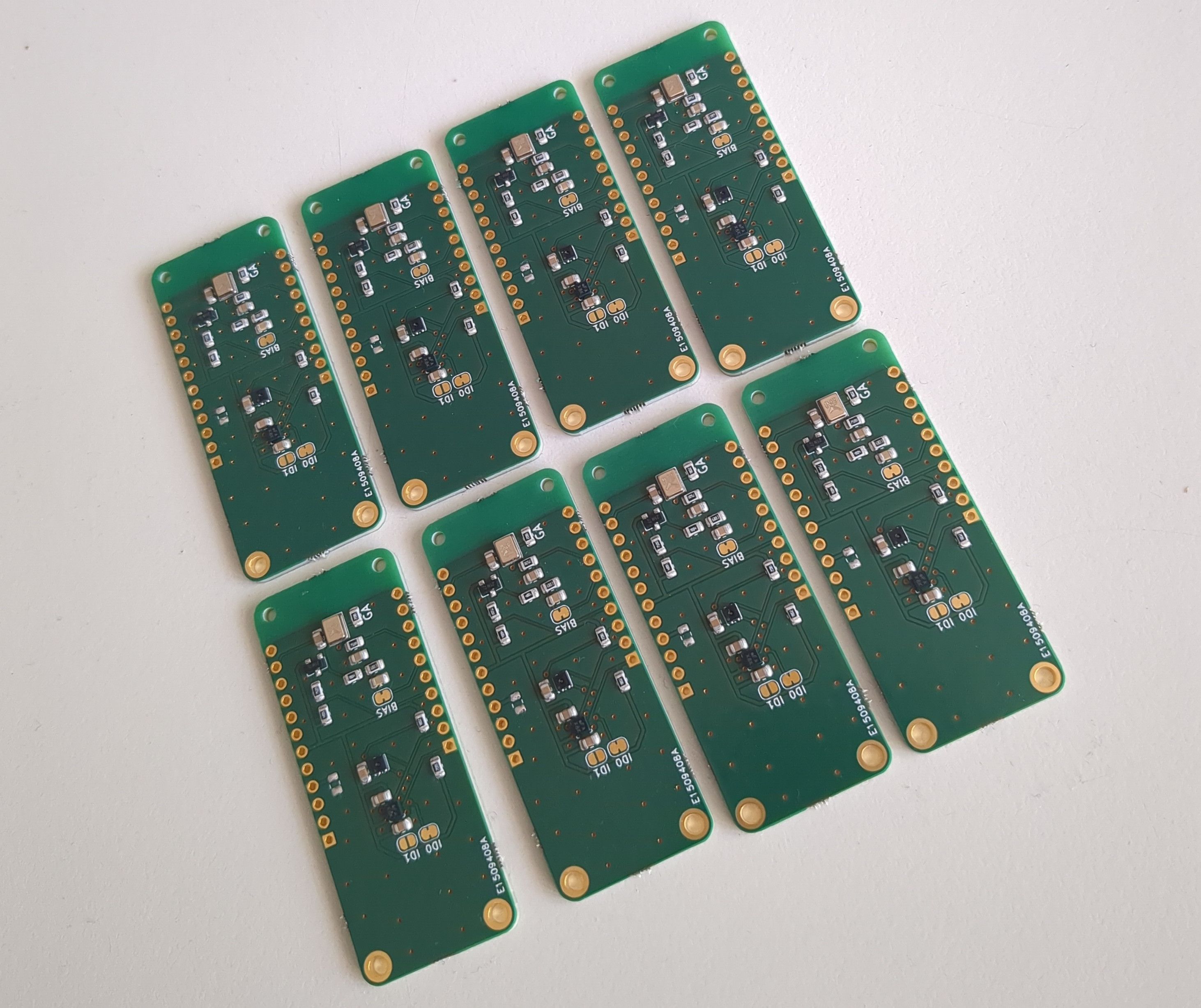

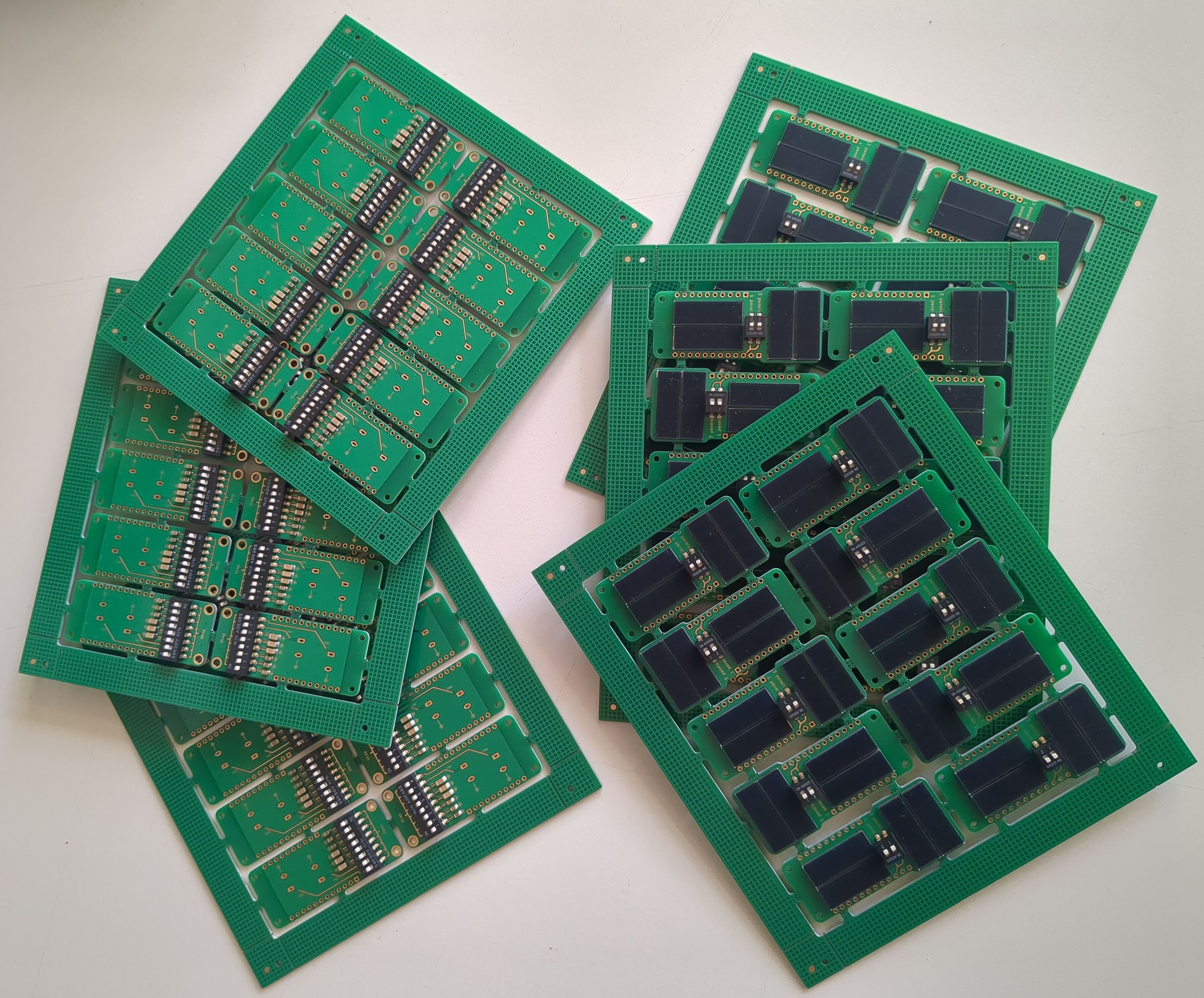

Here’s a few pictures of the assembled Riotee Shields:

Our ambitious plan was to ship all products end of May (now). Unfortunately, we have to postpone this shipping date by multiple weeks due to a major set-back during production. Here’s what happened:

Paste Printing Problem

If you remember, we already had to switch manufacturer for the Riotee module once. The new manufacturer happily accepted the order. We agreed that they will assemble one panel of eight modules that we personally test on-site before running the remaining panels through the assembly line. Two weeks after placing the order, we received a call that production was planned for the next day. When we arrived at the fab the next day, we were greeted with an unpleasant surprise: None of the produced modules was functional. A few test prints without components revealed the problem: The manufacturer’s solder paste printer could not produce small enough dots to solder the 350 um WLCSP package without solder shorts. Apparently, they had never worked with such a small package before. After a bit of research it turned out that the solder paste printer is only specified for a dot size of 330 um which leaves only 20 um between two dots - way too little to avoid shorts. Of course, the manufacturer should have noticed that as part of a feasibility analysis before accepting the order. This left us with two problems:

In order to load the components into the feeders of a pick and place machine, a few inches of the plastic tape covering the components on the cut tape strips and reels have to be peeled back. When removing the tape from the feeders, the components which aren’t covered anymore drop from the tape and can’t be used for automatic assembly anymore. On average, we were missing 35 components from each tape. While we generously factored in hundreds of additional parts for the passive components, we only bought a few extra components of the expensive active components. After losing 30-ish parts of each kind we were left with too few components to manufacture the target batch size required to fulfill the campaign. Fortunately, we were able to re-order all missing components. The manufacturer accepted their responsibility for the component loss and for multiple hours of extra work and we are currently working on a solution for compensation.

The other problem is a major delay in production. While we had factored in multiple weeks of delay, a lot of that buffer was already eaten when we had to switch manufacturer the first time. After this set-back it took almost two weeks more to obtain quotes from other manufacturers and place the new order. Many of the larger German fabs are over-booked and offered lead times starting at six weeks. We settled for a Berlin-based manufacturer who we’ve been working with before. They offered a lead time of fifteen working days, so we hope to get the Modules assembled by mid-June. Since the modules are required for assembling the Riotee boards, assembly of boards (and probes) can only start after the modules have been assembled and tested. Therefore, we won’t be able to ship to Mouser before end of June/beginning of July.

We thank you again for supporting the campaign and for your patience waiting for Riotee.