Project update 7 of 11

Leak Acoustics and Campaign Status

by Mike HThe physical nature of the leak aperture is important to understanding the capabilities of the AquaPing sensor. This issue can be characterized by measuring the maximum free-space stand-off distance at which various types of simulated leaks can be reliably heard. The following tests show that bigger leaks are not always easier to detect than smaller ones.

Plumbing

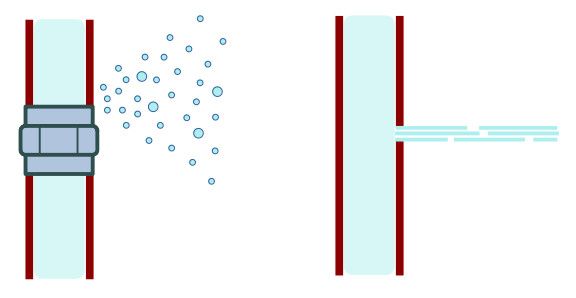

Two examples of leaks from pressurized plumbing are sketched below. On the left, a spray is emitted at a loose coupling between two pipe sections. On the right, a distinct stream is created as water escapes through a pinhole. We want to determine the relative difficulty of detecting these leaks using acoustics.

An experiment was done with three different simulated leaks, listed in order of increasing flow rate:

- Leak One: Plastic irrigation fogger producing a flow of 0.04 gpm (refer to previous update).

- Leak Two: Smooth, circular, 0.38 mm diameter hole drilled into 1⁄4 inch copper tubing, producing a flow of 0.06 gpm.

- Leak Three: Smooth, circular, 0.76 mm diameter hole drilled into 1⁄4 inch copper tubing, producing a flow of 0.18 gpm.

All three sources are pressurized from the water utility. There are no acoustic barriers in the path. The AquaPing is moved to the maximum stand-off distance where the leak acoustics can be reliably detected.

The tests show that the leak orifice dramatically influences the acoustics and hence stand-off detection distance. Leak One emits a flow that is 33 percent smaller than Leak Two, yet Leak One is detected at almost three times greater distance. This is because Leak One generates a fine mist accompanied by a strong, high-frequency acoustic signal, whereas Leak Two renders as a quieter, Laminar flow jet.

Leak Three has a hole that is twice the diameter of Leak Two and also discharges water in a collimated Laminar jet. Even with a flow rate that is 4.5 times higher than the irrigation fogger, the much lower flow from Leak One is still detected at a greater stand-off distance.

This is clear evidence that the rate of water flow is not well correlated with the detected sound level. Since most plumbing leaks occur at cracks, seams, or loose fittings, they will likely produce a spray and concomitant high-frequency acoustics. These are the frequencies targeted by the AquaPing.

Another interesting observation is that simulated Leaks Two and Three exhibit a more pronounced acoustic emission anisotropy compared to Leak One. This is consistent with the different water emission patterns. The ability to hear a pinhole leak depends on its orientation to the sensor.

Appliances

A water faucet is essentially a controlled leak. High frequency acoustics are generated when the faucet is opened, except at extremely low flows characterized by intermittent drips. The acoustics originate primarily at a valve located inside the faucet housing, not from the water exiting the spigot. The metal housing acts as a partial sound barrier that reduces the signal level compared to a pipe crack or leaking fitting. In the latter, sound propagates directly into free space, attenuated only by weak atmospheric absorption.

Measurements with a variety of faucets show that sensitivity to water flow critically depends on the different designs and construction. This results in varying acoustic emission strength and frequency shaping. Nevertheless, leaky faucets, valves, and stuck toilets are examples of plumbing problems that can be identified acoustically.

Noise Alert Pin

The AquaPing recognizes when it is operating in a noisy environment. This occurs when there is an emergence of frequent, fluctuating, high-frequency acoustics at levels significantly higher than were present during the training session. While not expected to be representative of a small leak, this noise may provide an indication of anomalous activity in the vicinity. This can arise from many causes such as water escaping at a high flow (i.e., large leaks) or even unauthorized human activity. The latter might occur during a break-in to what should be quiet, unoccupied property.

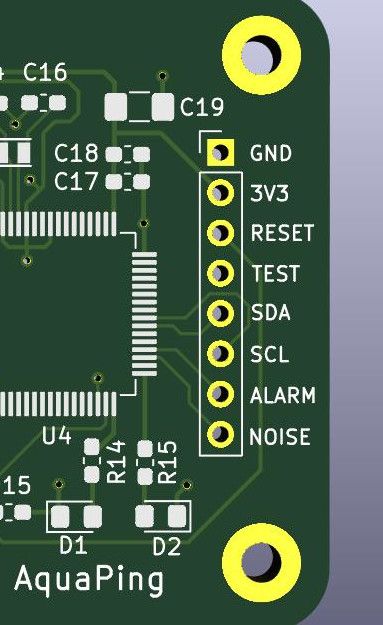

To take advantage of this capability, the controller can poll the appropriate noise warning byte in the AquaPing status array. Our production device will add a digital line to the connection header labeled NOISE (see PCB detail below). This allows the controller to monitor for an immediate low-to-high interrupt without the need to communicate with the sensor on the I2C bus. Use of the NOISE alert pin is entirely optional and is included for more design flexibility.

Campaign Ending

The AquaPing crowdfunding campaign will end shortly (fully funded!) and with it, the opportunity to place pre-orders. We’d like to thank all the backers who helped us reach our funding goal.

The next step is contract manufacturing. We are ahead of the chip shortage and have enough inventory to make on-time delivery to all our backers. We expect a new supply of microcontrollers to become available toward the end of 2022, which should let us re-stock. We’ll be sure to keep you updated throughout the process.