Project update 24 of 28

April Backer Update

Dear Backers,

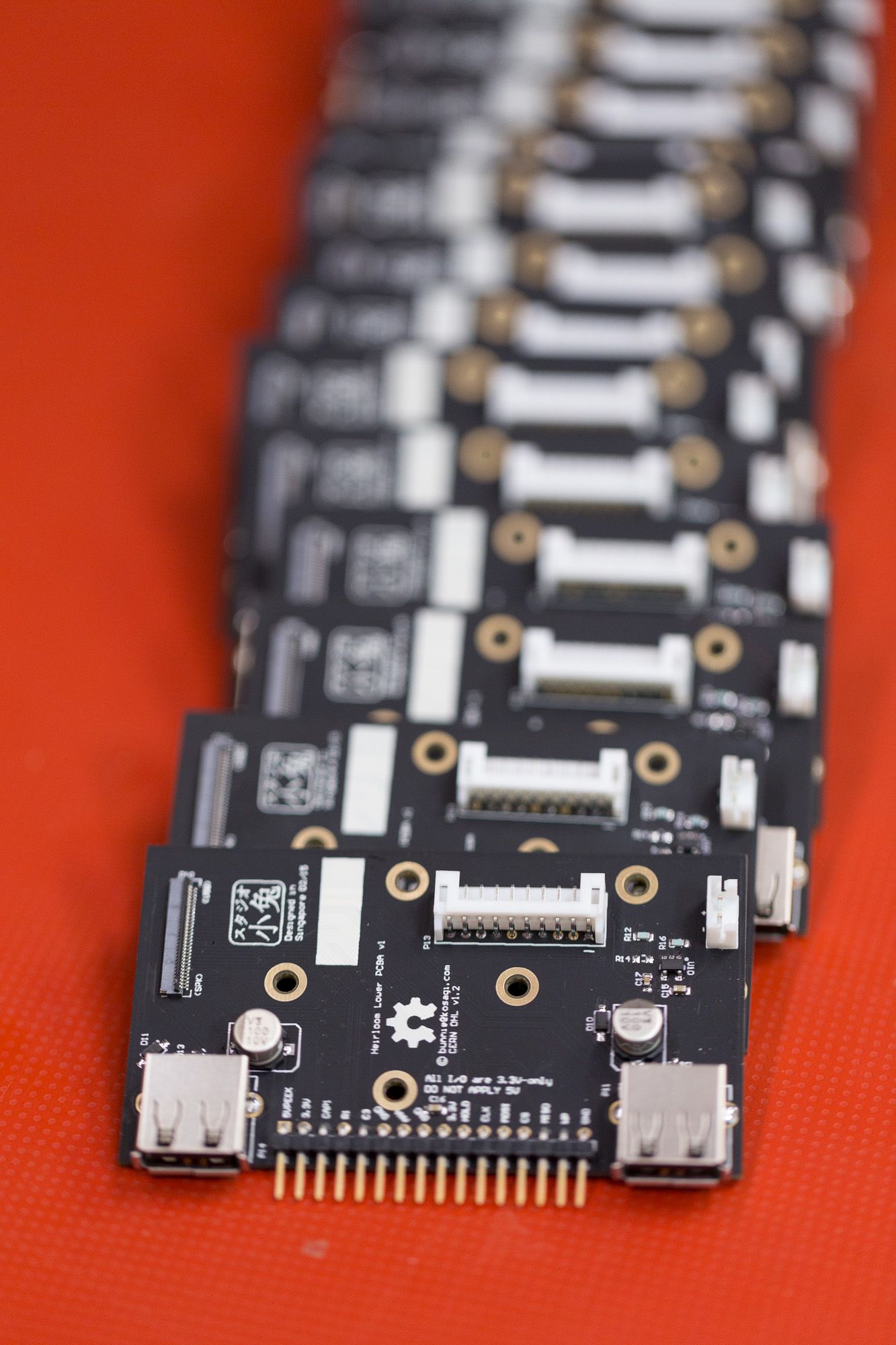

We apologize for the long pause since our last update. However, we think the best update anyone can get is a tracking number for their order. To date, we’ve managed to fill all the mainboards, desktops, and about 25% of the laptop orders. We’re currently cranking laptops out at a rate of about 30 per week, which means we’ll be finished with the bulk of the campaign orders in about 4-5 weeks.

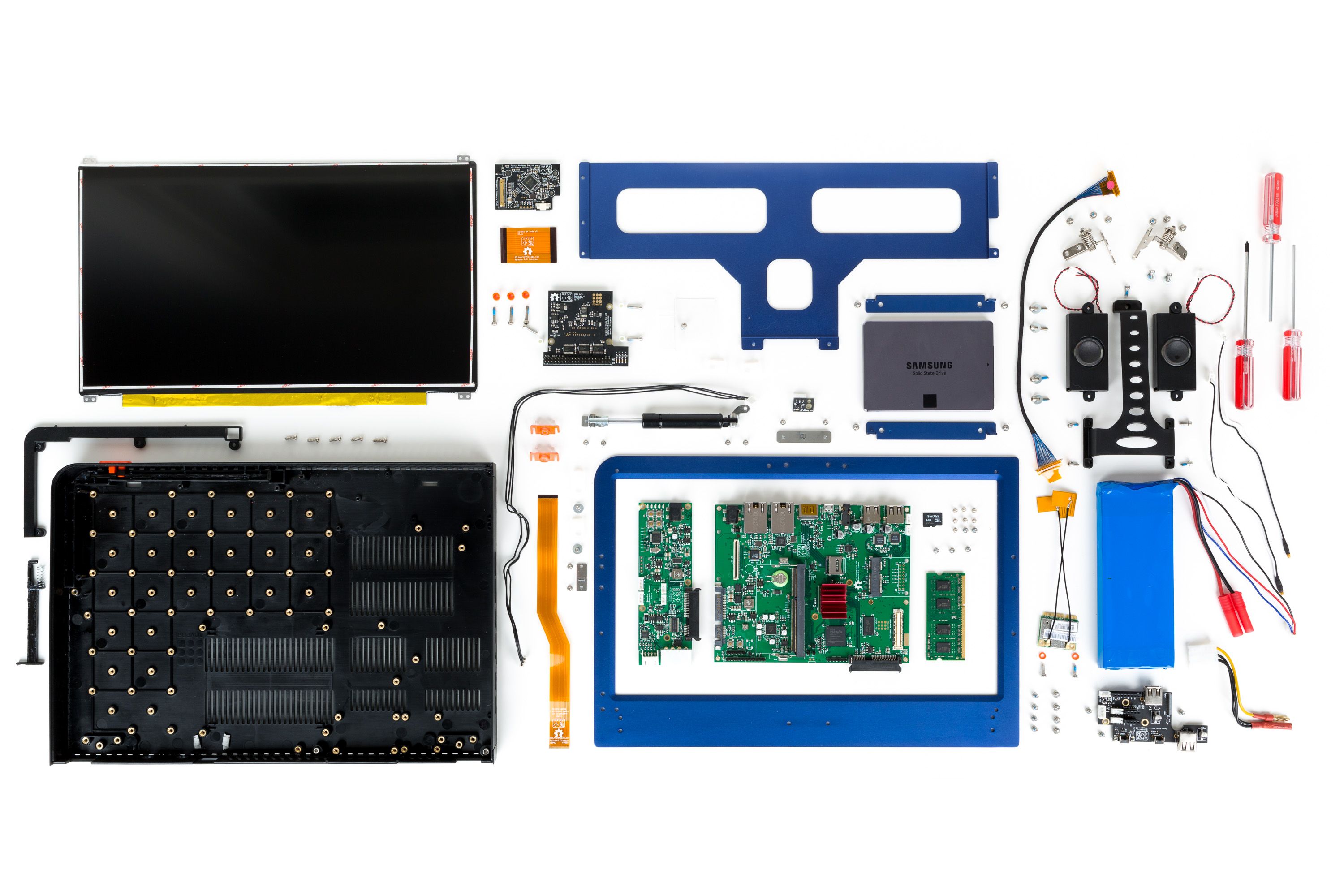

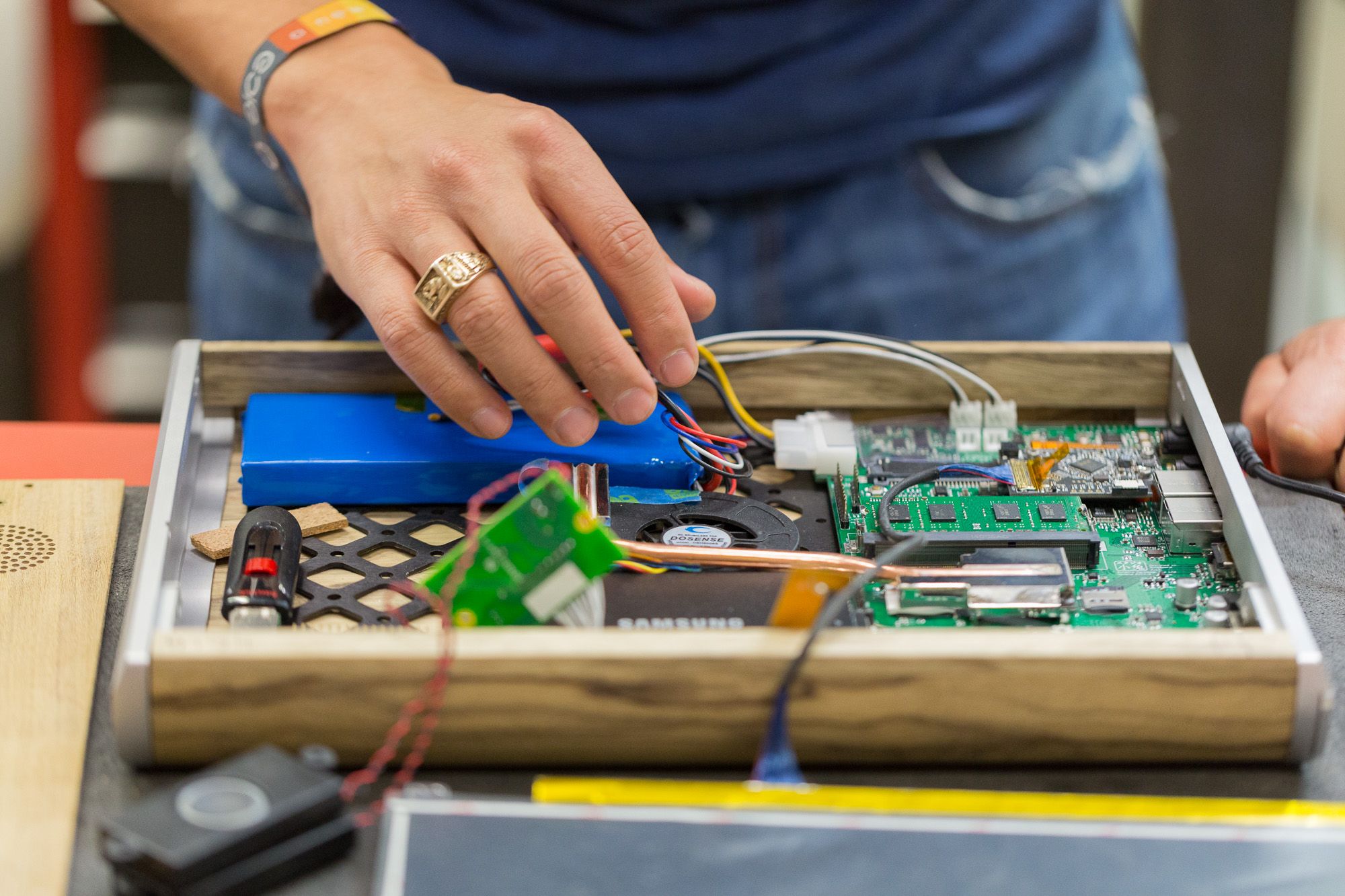

Our relatively slow rate of production belies the smallbatch nature of the Novena laptop. Laptops are complicated products, and have a lot of pieces in them; assembling them is labor intensive, and requires many steps. Because our lot size is so small, it’s not economically feasible to invest in automated tooling and dozens of production lines running in parallel.

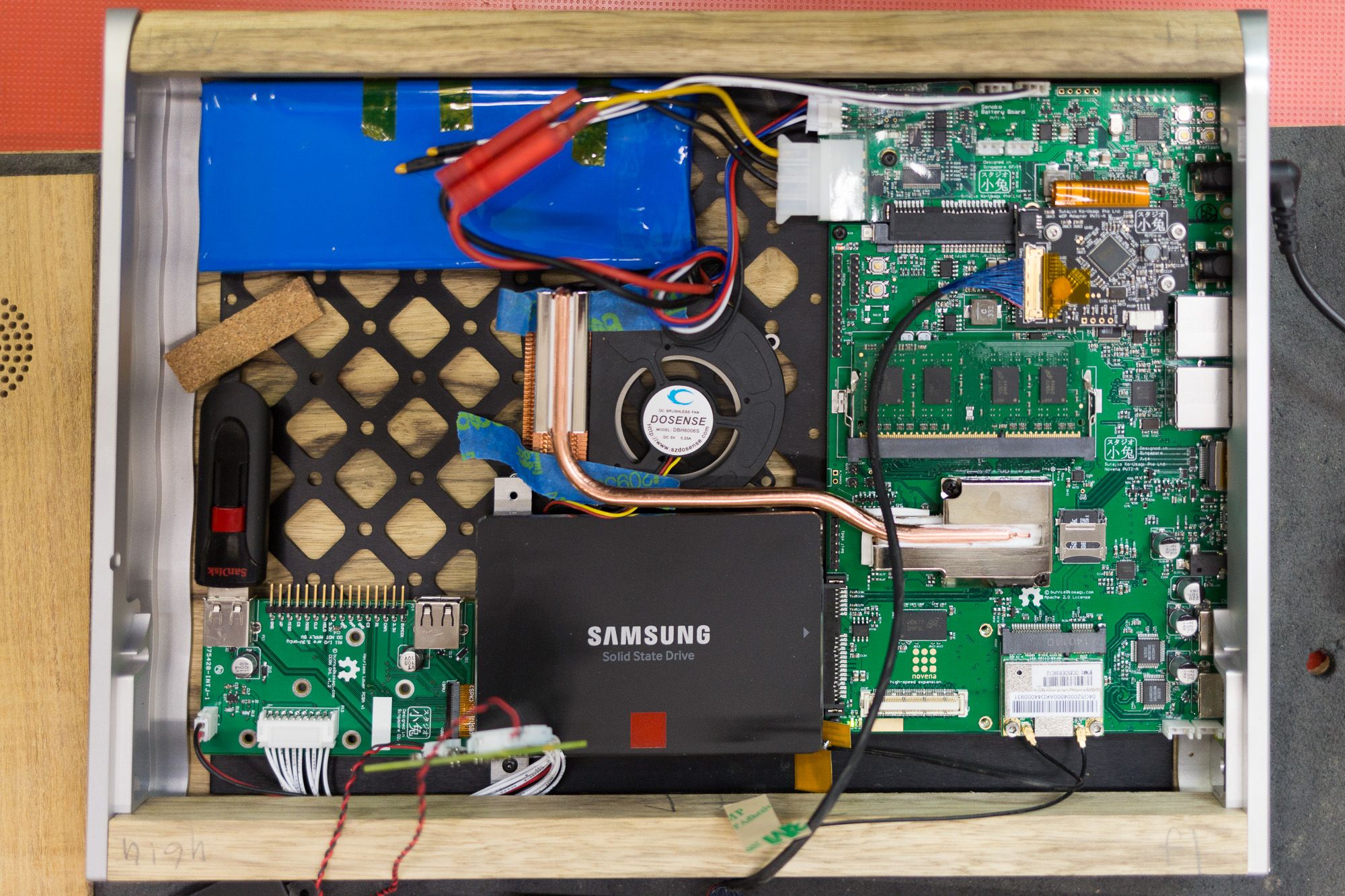

That’s a lot of parts! See a larger version.

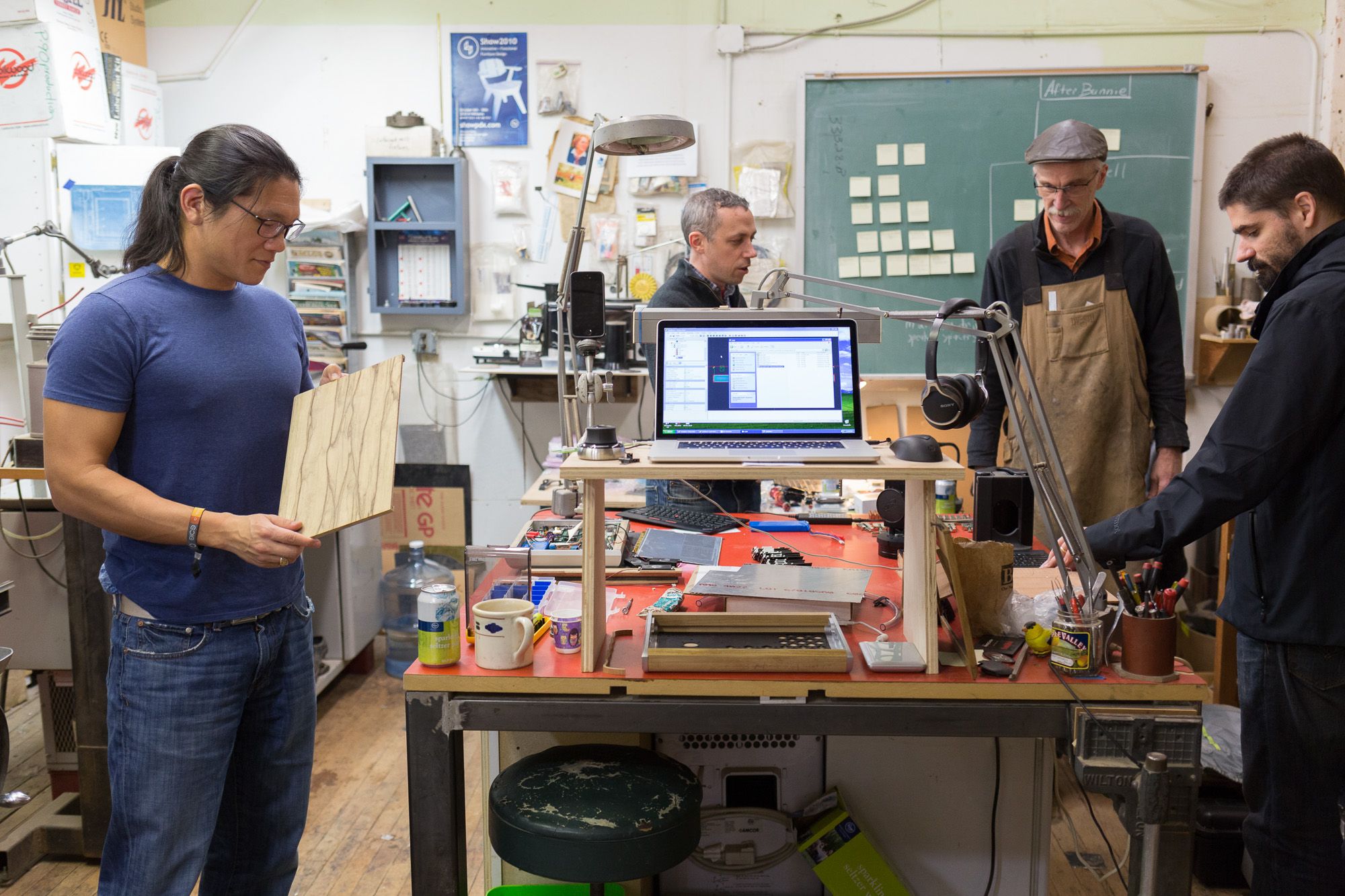

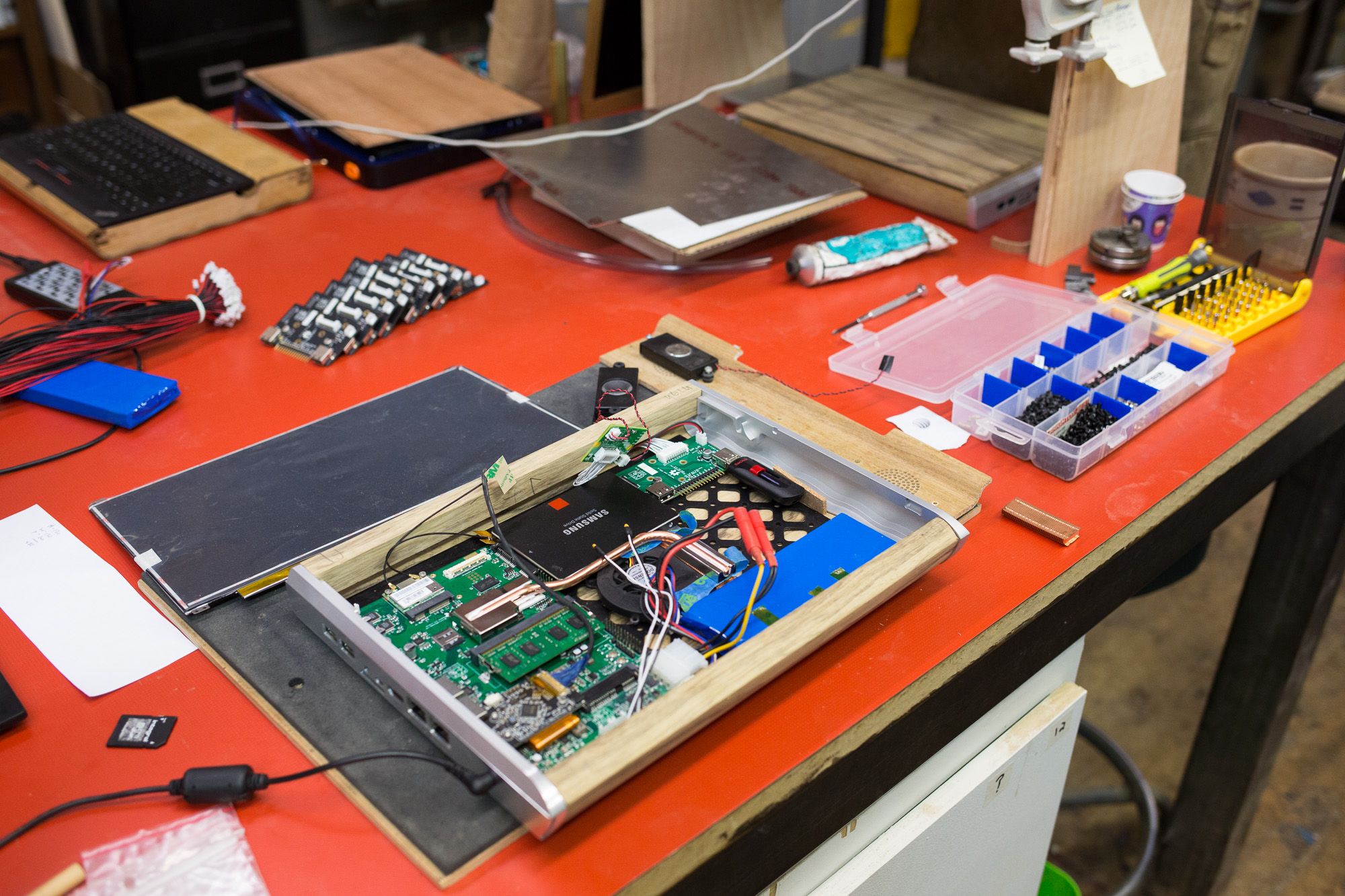

The Heirloom laptop, of course, is an even more bespoke product than the “consumer” Novena laptop. At a total production run of 12 pieces, these are true handcrafted items. With mainline laptop production finally humming along, bunnie was able to spend a week in Portland, Oregon working side by side with Kurt Mottweiler to hammer out all of the final open issues on the Heirloom devices.

We’re very excited about and proud of the way the Heirloom laptops are coming together. In a literal sense, Heirloom laptops are “grown” – important structural elements come from trees. While we could have taken the easy route and made every laptop identical, we felt it would be much more apropos of a bespoke product to make each one unique by picking the finest woods and matching their finish and color in a tasteful fashion. As a result, no two Heirloom laptops will look the same; each will be beautiful in its own unique way.

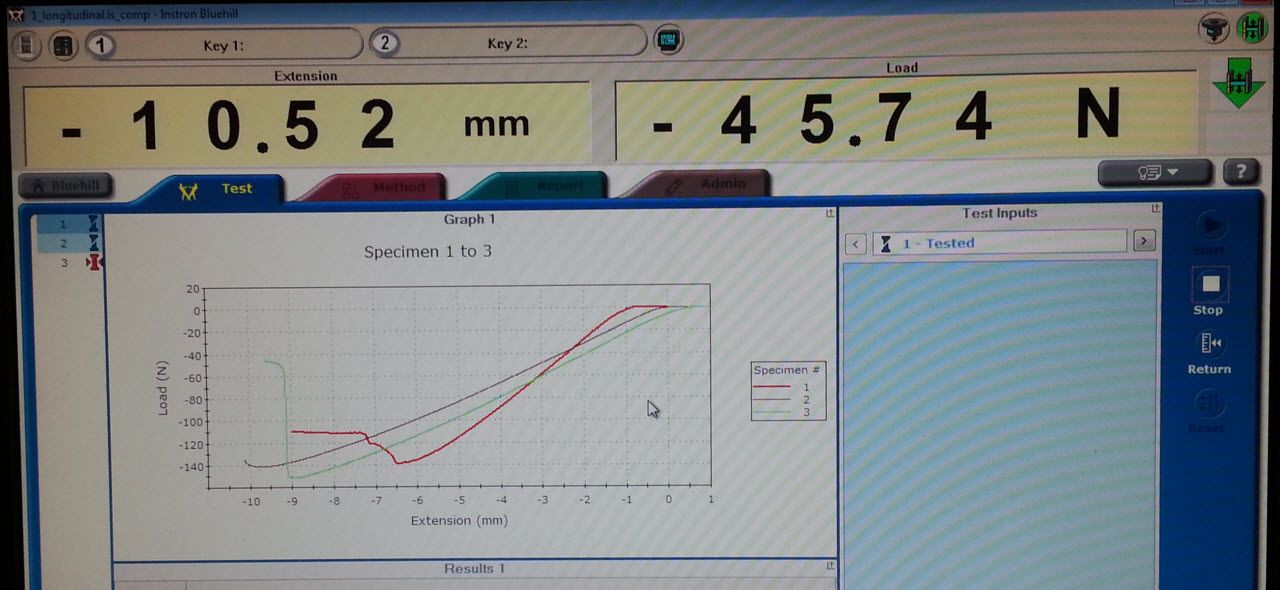

There’s a lot of science and engineering going into the Heirloom laptops. For starters, Kurt has created a unique composite material by layering cork, fiberglass, and wood. To help characterize the novel composite, some material samples were taken to the Center for Bits and Atoms at MIT, where Nadya Peek (who helped define the Peek Array) and Will Langford characterized the performance of the material. We took sections of the wood composite and performed a 3point bend test using a Instron 4411 electromechanical material testing machine. From the test data, we were able to extract the flexural modulus and flexural strength of the material.

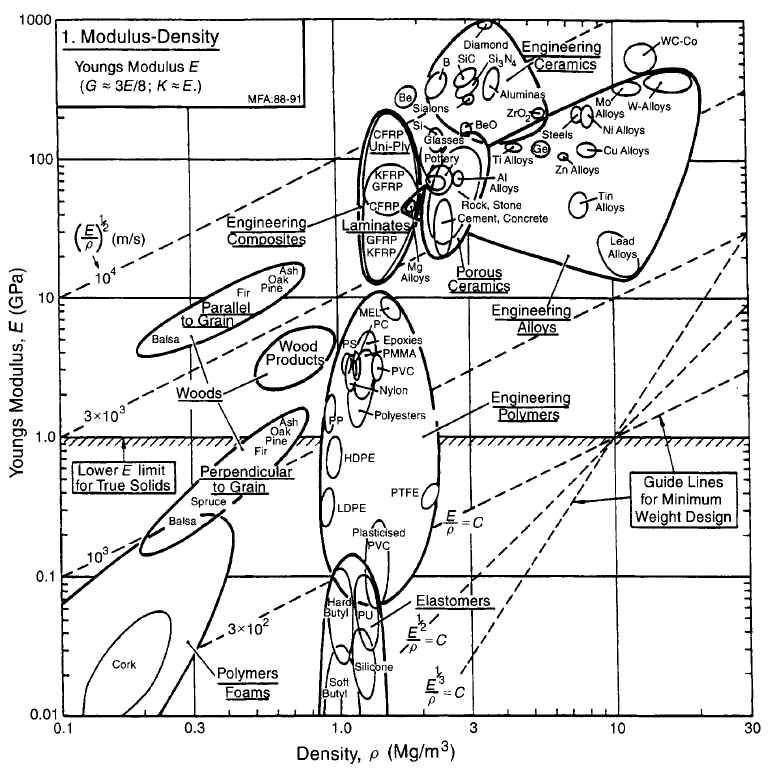

I’m not a mechanical engineer by training, so words like “modulus” and “specific strength” kind of go over my head. But Nadya was kind enough to lend me some insight into how to think about materials in this context. She pointed me at the Ashby chart, which like some xkcd comic panels, I could stare at for an hour and still not absorb all the information contained within.

For example, the Ashby chart above plots Young’s Modulus versus density of many materials. In short, the bottom left of the chart has bendy, light materials – like cork – and the top right of the chart has rigid, heavy materials, like Tungsten. For a laptop case, we want a material with the density of cork, but the stiffness of plastic. If you look at the chart, wood products occupy a space to the left of plastics, meaning they are less dense, but they have a problem: they are weak perpendicular to the grain, and so depending on the direction of the strain, they can be as yielding as polyethene (the stuff used to make plastic beverage bottles), or stiffer than polycarbonate (the stuff layered with glass to make bulletproof windows). Composite materials are great because they allow us to blend the characteristics of multiple materials to hit the desired characteristic; in this case, Kurt has blended cork, glass fiber, and wood.

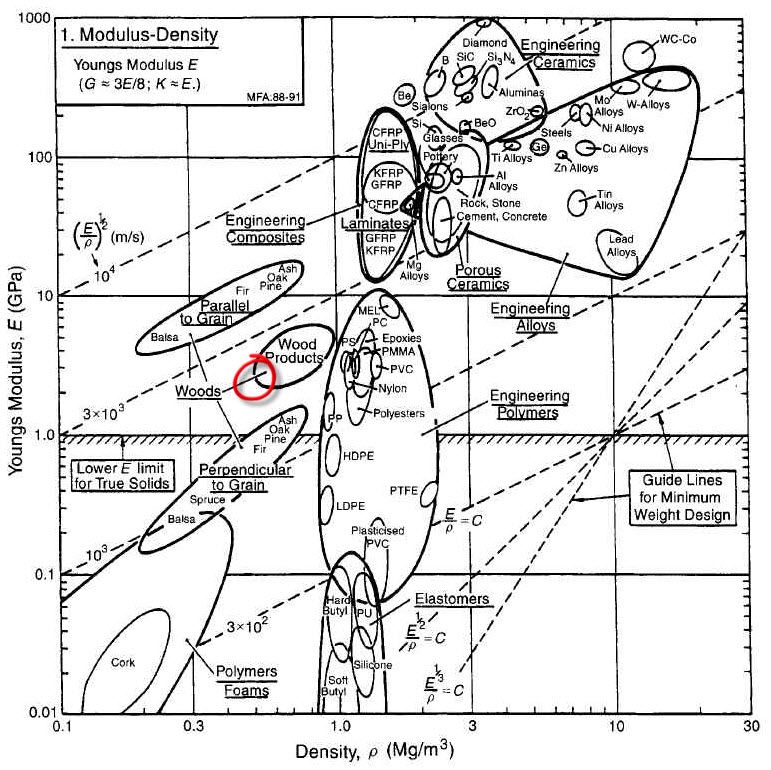

The measurements of the Heirloom composite show a flexural strength of about 33 MPa, and a flexural modulus of about 2.23.2 GPa. The density of the material is 0.49 g/cm3, meaning it’s about half the density of ABS. Plotting these numbers on the Ashby chart shows that the Heirloom composite occupies a nice spot to the left of plastics, and provides a compromise on stiffness based on grain direction.

The red circle shows approximately where the Heirloom composite lands. To be fair, measurements still revealed some directional sensitivity to the composite; depending on the grain, the modulus varies from about 2.2GPa to 3.2 GPa (and the diameter of the red circle encompasses this variability); but this is a much tighter band than the 10x difference in modulus indicated for pure woods.

Another thing to note is that during testing, the material didn’t fail catastrophically. Above are the graphs of load vs. extension as plotted by the Instron testing machine. Even after bending the material past its peak load, it was still mostly intact and providing resistance. This result is a bit surprising; we had expected the material, like normal wood, would break in two once it failed. Furthermore, after we reset the test, the material bounced back to its original shape; even after bending by over 10mm, once the load was removed you could barely tell it went through testing. This high fracture toughness and resilience are desireable properties for a laptop case.

Of course, there’s nothing quite like picking up the material, feeling its surprising lightness, and then trying to give it a good bend and being surprised by its rigidity and ruggedness. The Heirloom backers will get the privilege of feeling this firsthand; for the rest of us, we’ll have to settle with seeing circles on Ashby charts and graphs on computer screens.

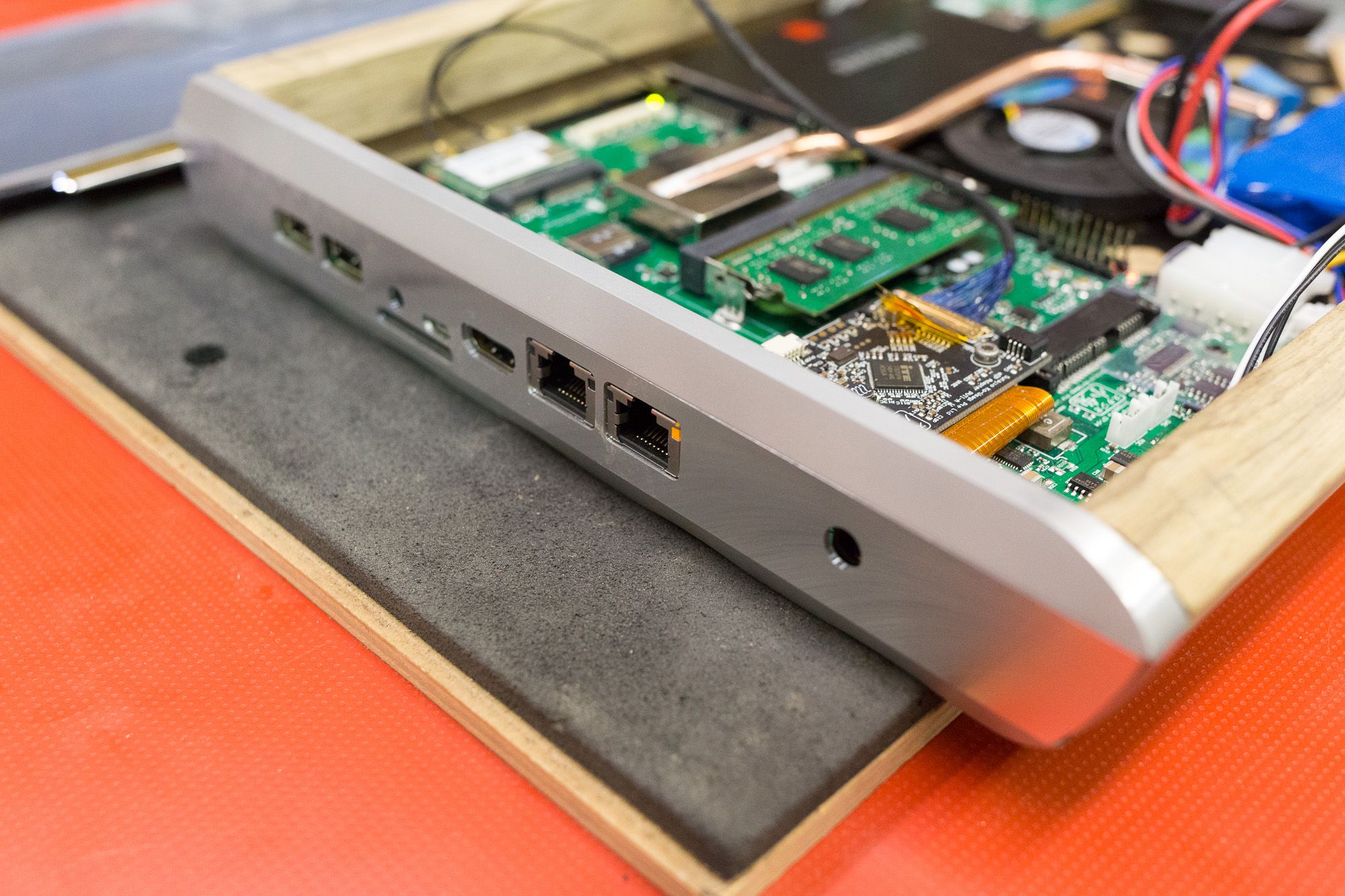

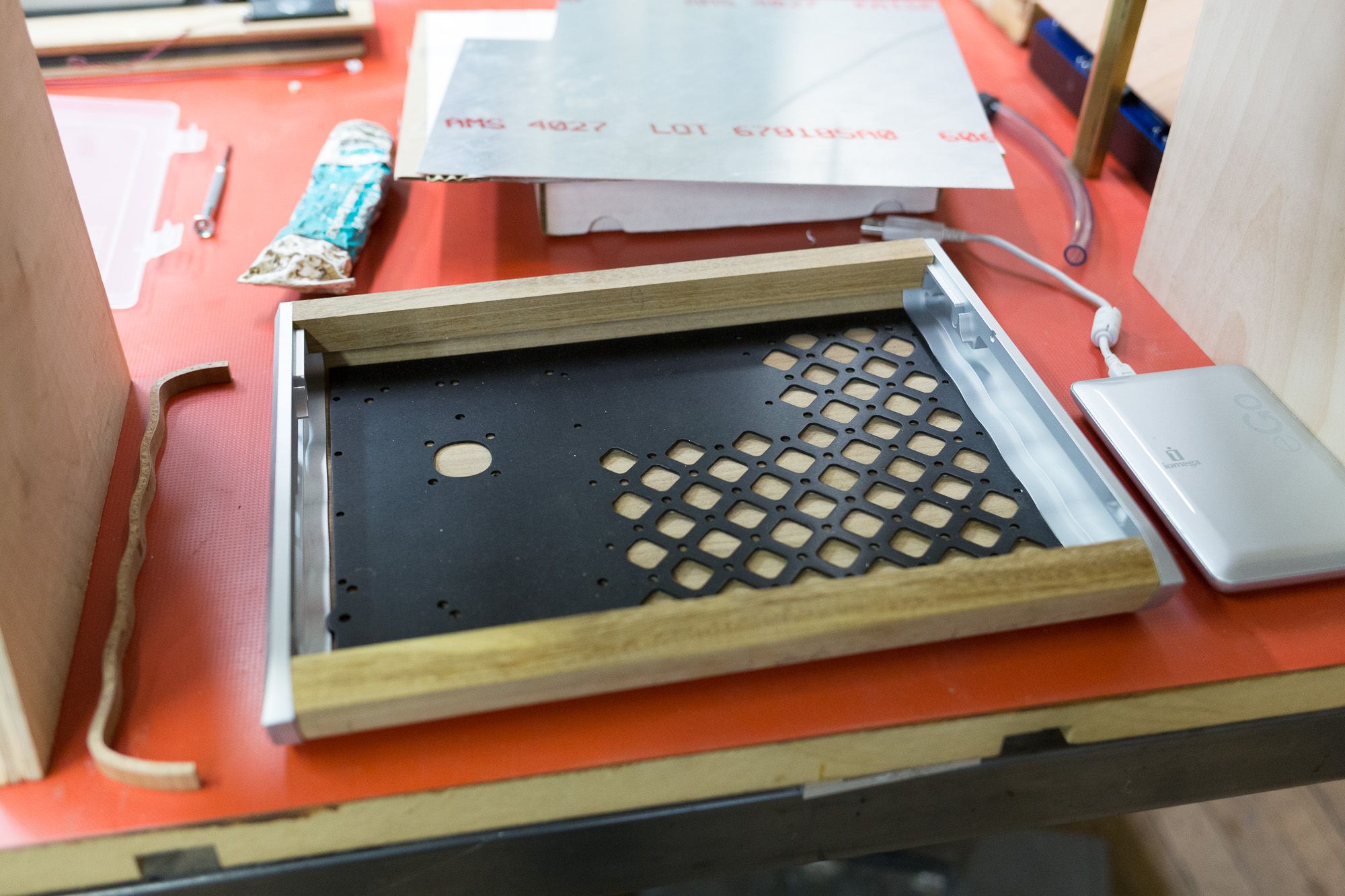

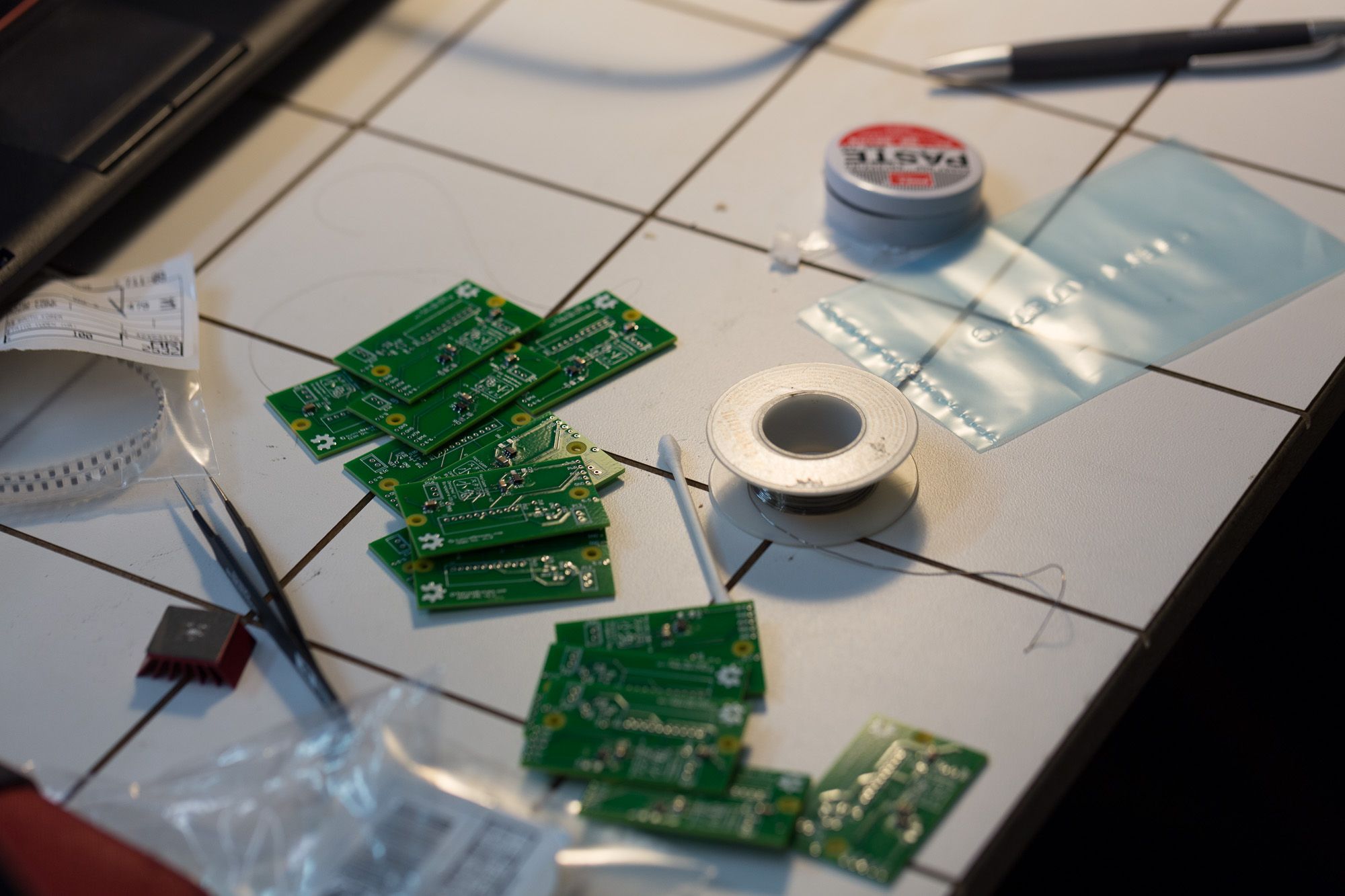

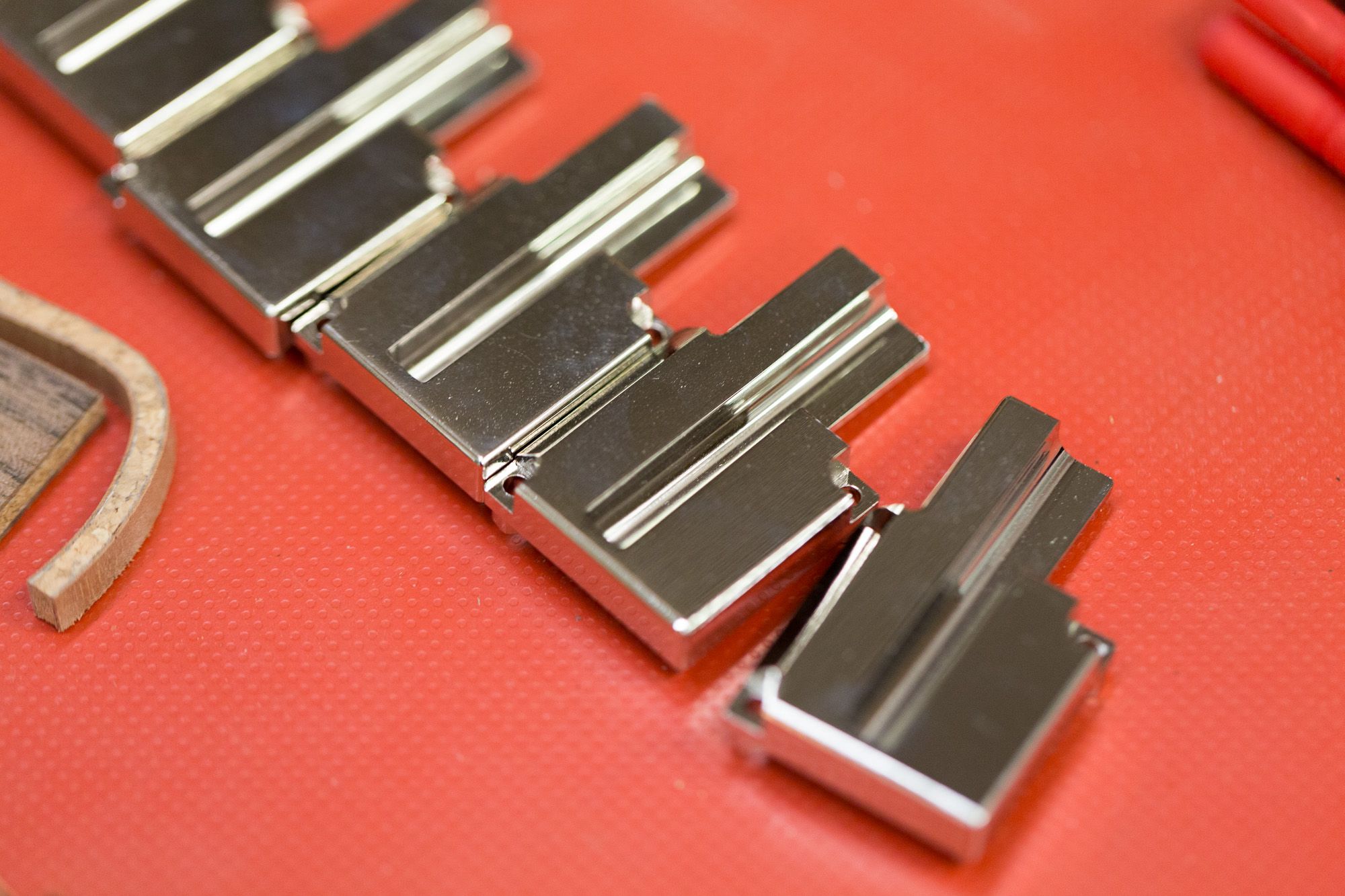

The clamshell form factor of the Heirloom required extensive reengineering of the supporting circuitry and mechanics of the mainline Novena design. The list of refactored assemblies include the breakout boards for the internal ports, the hinge, the Peek Array, the LCD cable and the heat sink assembly.

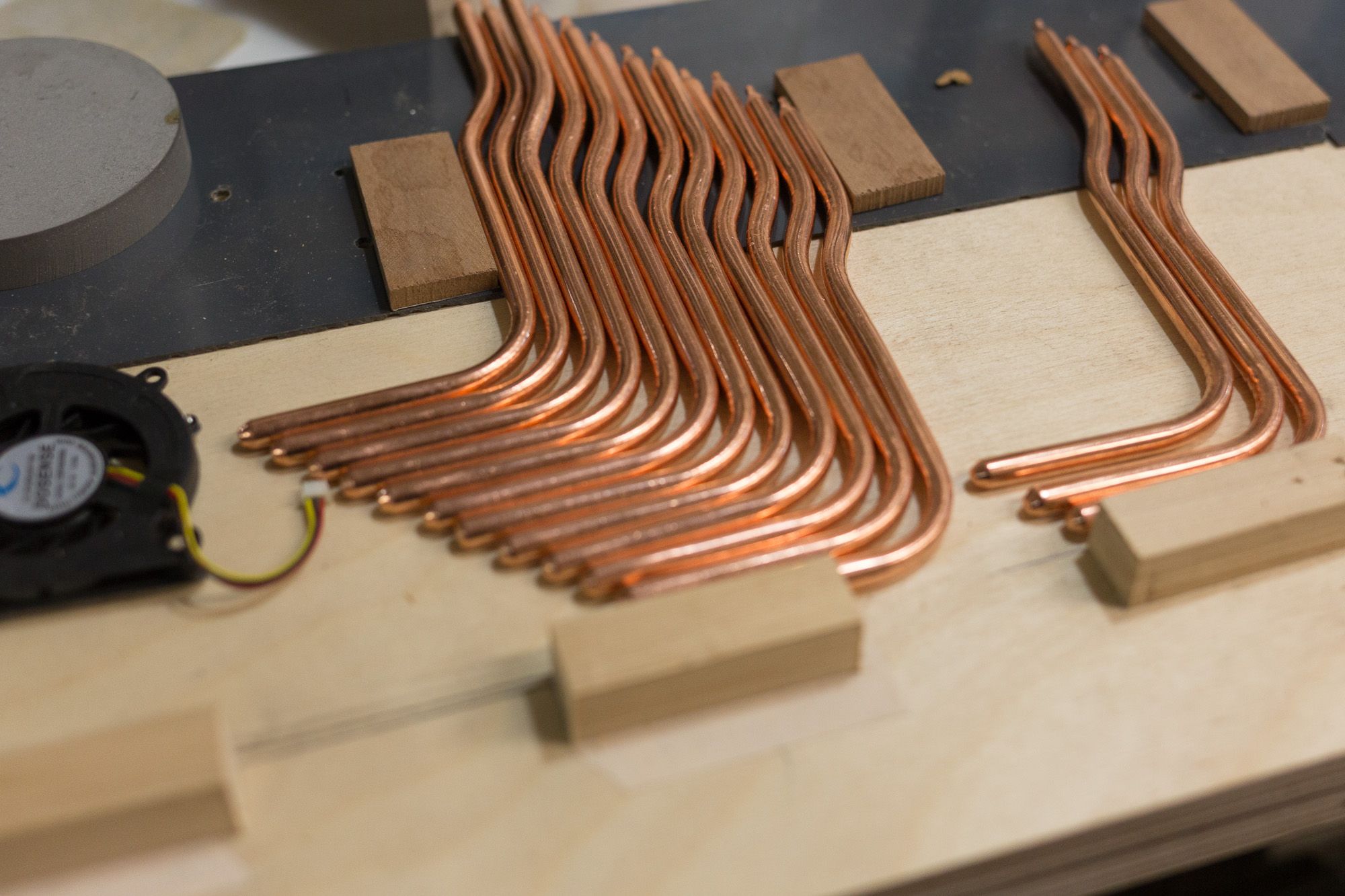

Unlike the mainline Novena design, the mainboard’s airflow is restricted by a keyboard resting immediately above it. This means we had to design an active solution to shuttle heat away when you’re cranking on all four cores. This involved a custom heat pipe, custom copper blocks, zipper fins and a customized fan mounting assembly. All of this had to be customized for just a dozen laptops.

At the moment, all the material for the Heirloom Laptops are staged at the workshop and all the major technical issues have been resolved. We’ve settled on the final layout of the components in the case, and we’ve made the firmware tweaks necessary to support the new cooling system. However, there’s still a substantial amount of elbow grease required to trim, assemble, finish, and test all the pieces. Artisan craft takes time, and we’re going to leave Kurt to do what he does best. Our best guess is probably we’ll start shipping Heirlooms in about 2 months, but if Kurt feels he needs a little more time to make things perfect, then xobs and I are willing to wait on shipping so that Kurt can deliver a product with a craftsmanship that he’s happy with.

This brings us to the question of the fate of the Novena project going forward. Clearly, the Heirlooms are a once-in-a-lifetime production run, and so the intrepid backers of our campaign will also be the only ones to ever own one: the only way to get an Heirloom is to be an heir (or if you’re lucky, one will end up on the secondary market).

For the mainline Novena product, we’re in a bit of a conundrum. There seems to be an expectation among some prospective buyers that now the campaign is done, Novenas should be “in stock” and available for impulse purchase with overnight shipping. After all, that’s how most laptops are sold, right?

The problem with this assumption is that someone has to take a risk on how many laptops might get sold, to enable products to be just sitting on the shelf waiting for a buyer. That someone who has to take the risk turns out to be…us. And we’re just a couple of guys working out of a home office. Frankly, there was a lot of customization and tooling involved; because of the small volume (relative to mainstream laptops) we didn’t make much money off of the Novena campaign – it was a labor of love. At the end of the day, we simply don’t have the hundreds of thousands of dollars required to pre-build units and have them sit in Crowd Supply for months hoping someone buys them.

As a result, our next move is to sell off our production excess as spare parts. We currently have the “hot dog and buns” problem – hot dogs come in packs of 6, buns in packs of 8, and now that the party is over, we’ve got some extra buns, but not enough hot dogs to make a whole meal. Once the final laptops have been produced and we are 100% sure that all our backers will receive the units they are promised, with a reserve for the rare defective unit that gets out there, we’re going to tally what’s left over and make them available for people to buy. This means you’ll see a few battery boards, battery packs, eDP adapters, cables, LCDs, case kits and other odds and ends come available, while supplies last, on Crowd Supply in a bit over a month.

As for new production, we’re committed to supporting the Novena ecosystem by stocking main boards for the foreseeable future; we’ll take the cash risk to make sure a supply of this critical component is available, although there may be gaps in availability if demand picks up. It takes us about four months from commitment to shipment – many of Novena’s parts are ordered directly from other factories (Novena mainboards are actually made in the US!), and those factories take about 23 months to manufacture and deliver their stock to us – so we’ll endeavor to topup our Novena mainboard stock about twice a year. If we had a steady pipeline of orders, the effective latency of production would be less, but at our volumes every production run basically starts from scratch. This is the reality of low-volume, bespoke production.

Our commitment to build and inventory just the motherboards means we’re looking to lock up around $100,000 of our cash to serve the Novena community. It’s definitely a burden, but we want the world to know we’re serious about supporting the ecosystem; at the very least, we want the maintainers of various Linux distros to have sufficient confidence in on-going availability to use our motherboards to power their build farms, thereby ensuring timely software updates for our entire userbase.

Fortunately, Crowd Supply is stepping in to manage the production of non-motherboard parts & accessories for both desktop and laptops, and they’re planning to make these available for the foreseeable future. Like the motherboards, production will be run in small batches and if demand picks up, availability will be spotty as the factories come up to speed.

Thanks again to everyone who made this campaign so successful. You are a big part of this equation, so we’ll be listening in the IRC channels and forums for your feedback. We’re excited to see where the Novena community goes!

Happy hacking!

bunnie & xobs

We’ve included a gallery of additional Heirloom development & construction photos for you to enjoy.