Project update 10 of 13

The True Cost of Batch 3D Printing

Happy New Year everyone!

tl;dr version: I was able to bring a small batch of a cool product to market without going broke!

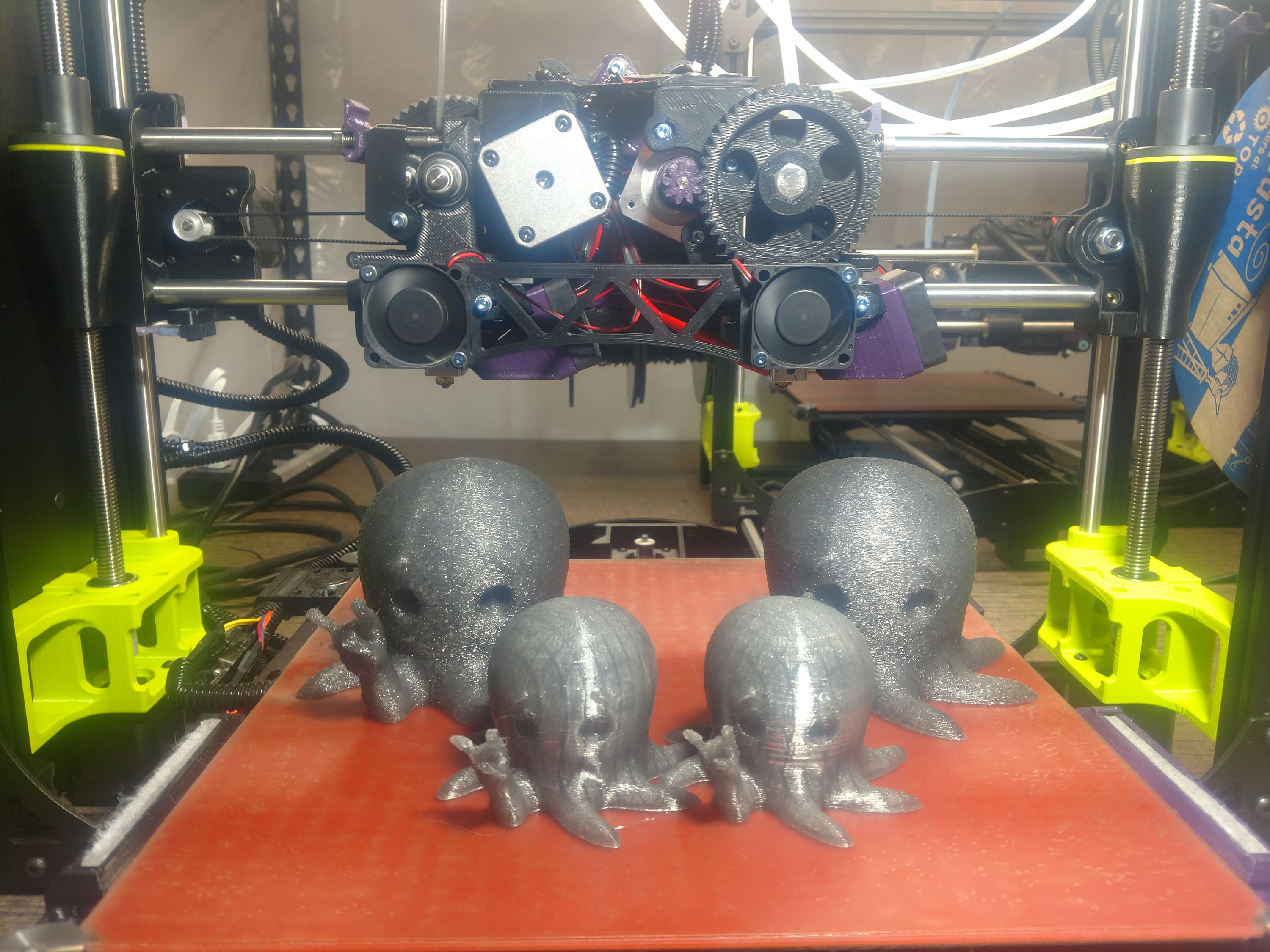

With all of the first batch Twoolheads shipped off and the holidays over, I’ve been able to take a step back and look at the numbers from the first production run using the Twoolhead. Overall the production went well, and the Twoolhead production setup put up some seriously impressive stats. The data and calculations are included in the BOM, but here are some highlights from the first production build of 6 Twoolheads:

- Total parts produced: 126

- Rejected parts: 6

- Yield: 95%

- Average per part print time: 34 min

- Average cost per part: $2.89

- Most expensive part: $6.38 (extruder body)

- Least expensive part: $0.61 (extruder latch)

- Total cost of printed parts per Twoolhead : $61.09

- Average output (0.5mm noz): 44 g/hr

- Average output (0.8mm noz): 70 g/hr

- Cost per gram (0.5mm noz): $0.21/g

- Cost per gram (0.8mm noz): $0.13/g

Cost breakdown:

Printer cost: 38% (full cost of TAZ6 + Twoolhead bundle spread out over 30 hrs/wk use for 1 year)

Labor: 32% ($15/hr to flip printers. This money went back into the coprintpro r&d fund, but should be accounted for.)

Material (CSL ABS): 27% ($42.95/kg, Chroma Strand Labs ftw)

Space cost: 2% ($1/sqft/month rental rate for commercial/industrial space in south Denver area)

Electricity cost: 1% ($0.0916/kWh (commercial electric rate in the Denver area)

If I had tried to create the Twoolhead with traditional injection molding, the up front cost would have been in the tens of thousands of dollars at least. Instead, I was able to deliver a cool product to early adopters at a reasonable price without going broke. Pretty cool, right?

If anyone has questions about the numbers or would like me to help calculate the cost of producing their own product with the Twoolhead, please reach out! Thanks again to everyone who supported the first production batch of Twoolheads!!

Cheers

-bam