Project update 3 of 7

Desk Frame & GridBox Housing

by Florian EichWe come bearing gifts! A small one, a bigger one and a preview of things to come.

The small one

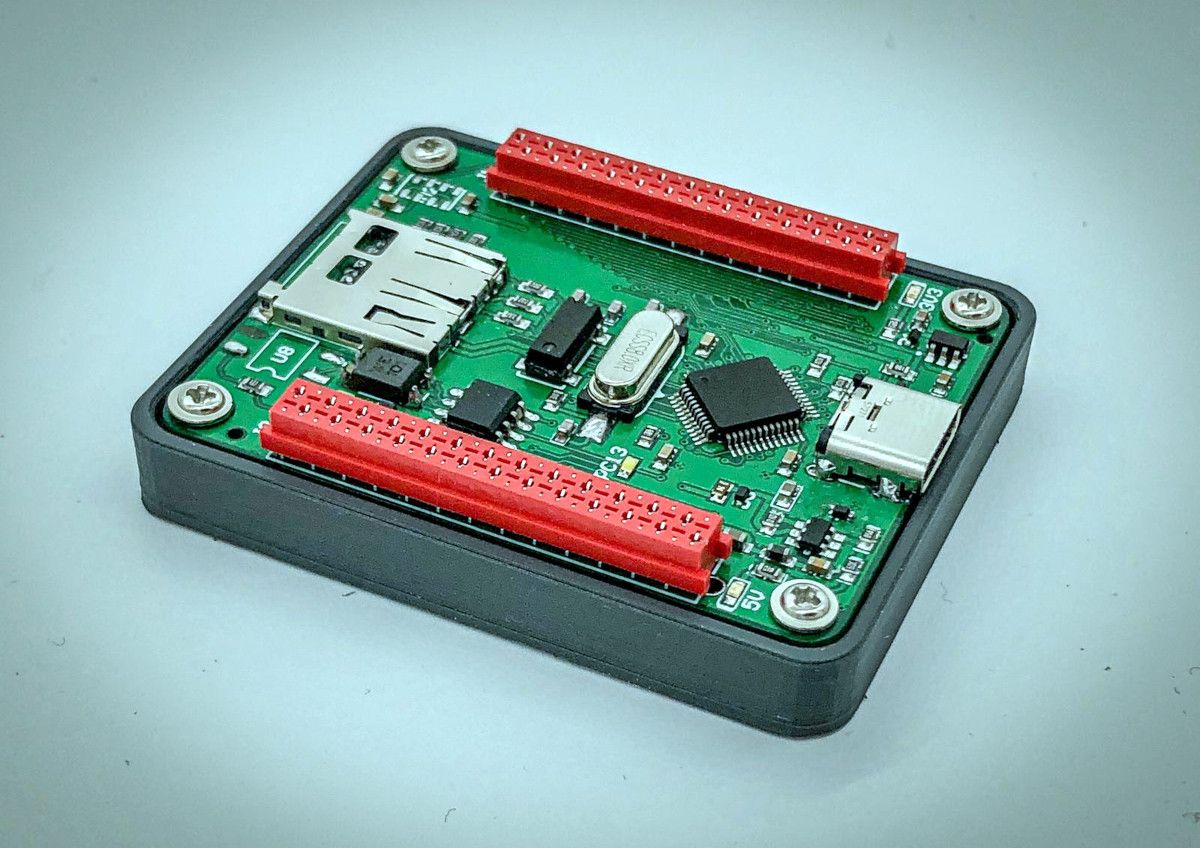

When working with development boards, the pins on the underside of the PCB are always naked on the surface - the desk, the mat or worse: something on a vehicle that has a lacquered finish! We solve this problem with the desk frame:

Yeah, yeah it’s a gimmick. And yeah, yeah, we’re perhaps a bit OCD about the whole "pins on the working surface" thing. Nevertheless, we like this little detail and wanted to share it with you. It also has holes, so you can use it to cleanly bolt your mini::base to the wall if you like!

The desk frame will be included with every starter pack. It’s 3D printed, and we’re also making the design available through our GitHub repo.

The bigger one

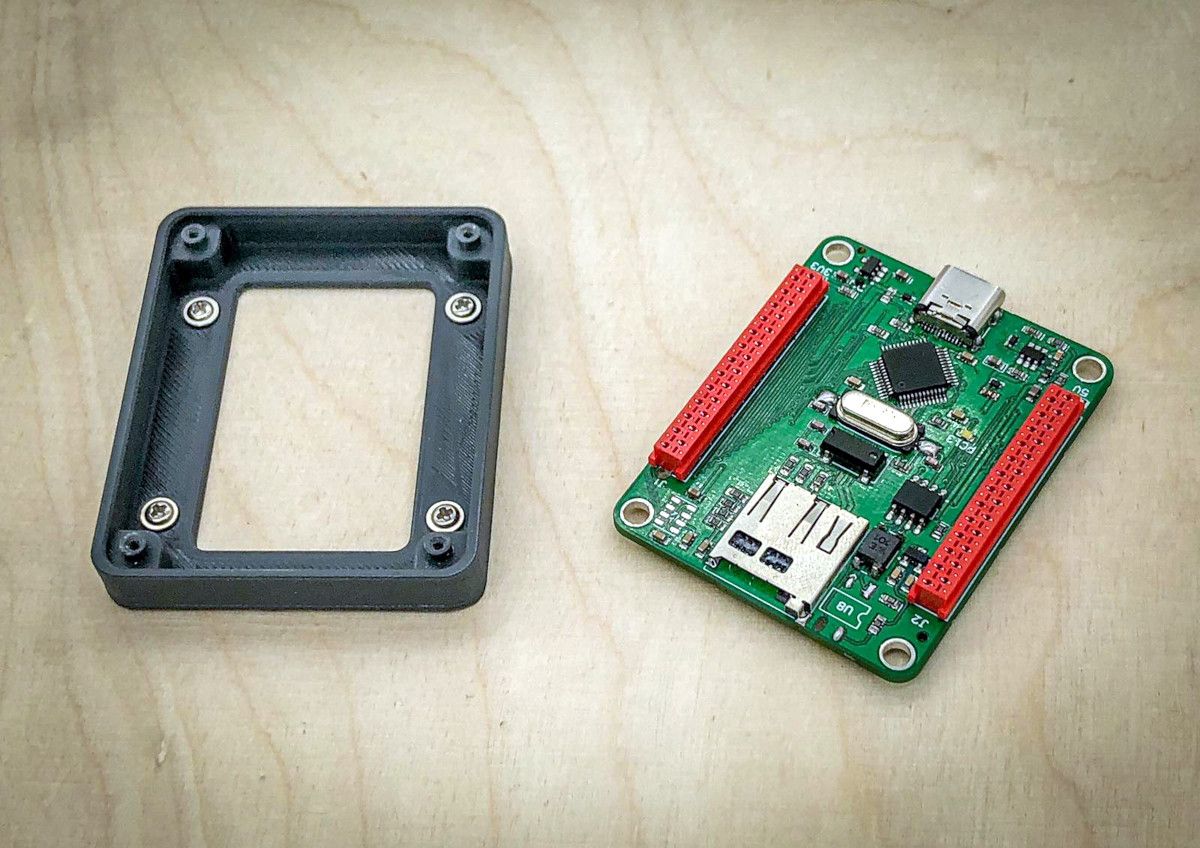

The philosophy of the project is to be ready for prototyping, and potentially ready for a product application. But to achieve that, the boards cannot stay "naked" - they need a housing! Ideally of course, we would like that housing to be solid, IP certified for a vehicle application, all the good stuff.

We can’t give the housing an IP rating (just yet), but we still believe this is a solid start to protect a mini::base plus mini::grid stack from the environment:

For our own applications, we are looking at machining the housing from aluminium, but it is designed to be 3D printed for now. We’re considering offering it for sale in both versions at some point, but in any case, we’ll be making the designs available through our GitHub repo.

The Preview

More housings are in the works! It’s not our primary focus so it’s not the fastest work ever, but there is a PitBox (housing for mini::base plus mini::pit) in the works, and then some other nice wrappings for things we haven’t announced yet. We’re worth subscribing to!

Stay up to date by checking out our campaign page, following our updates, and visiting the bmc::board website.